Heat radiation module and its heat pipe

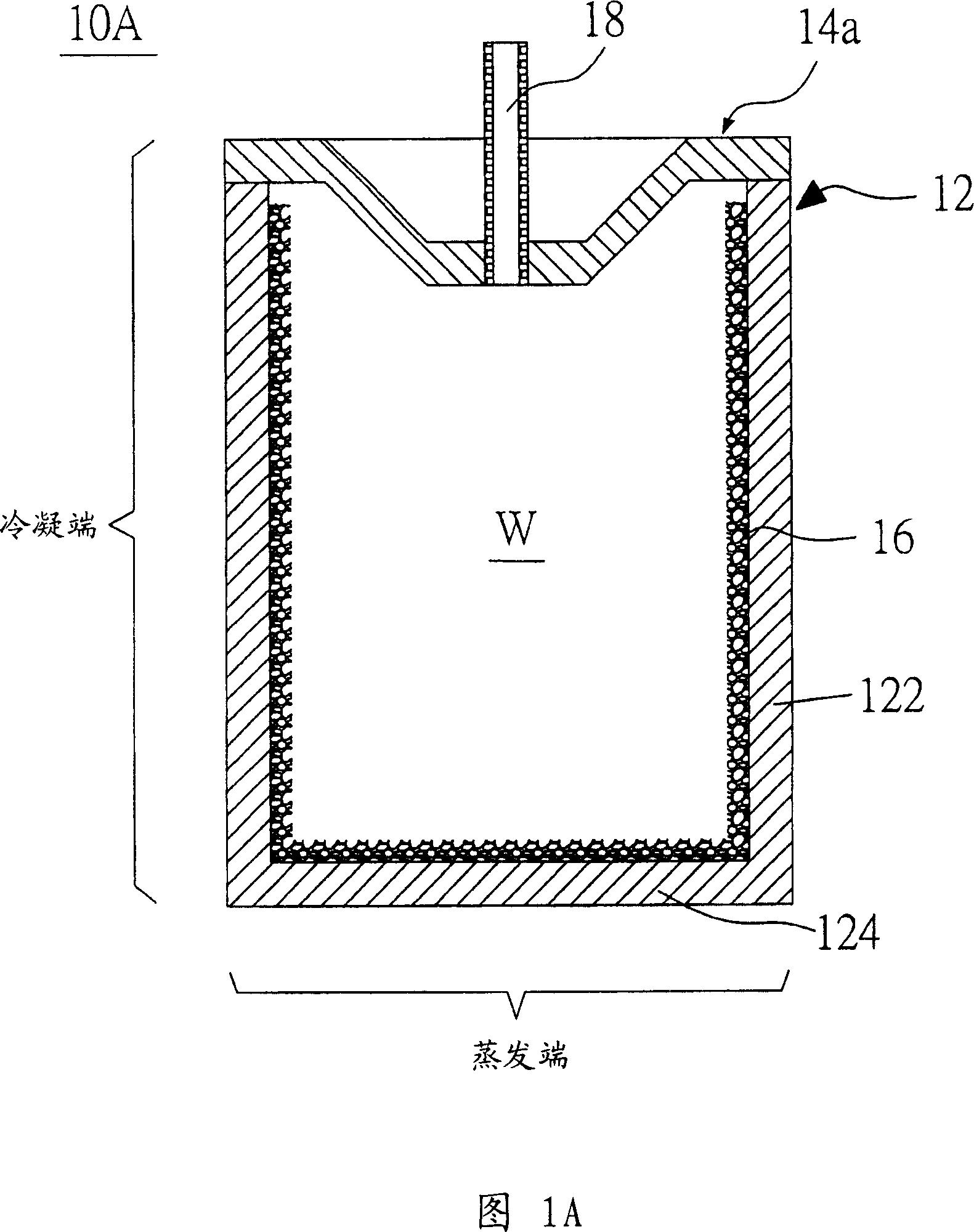

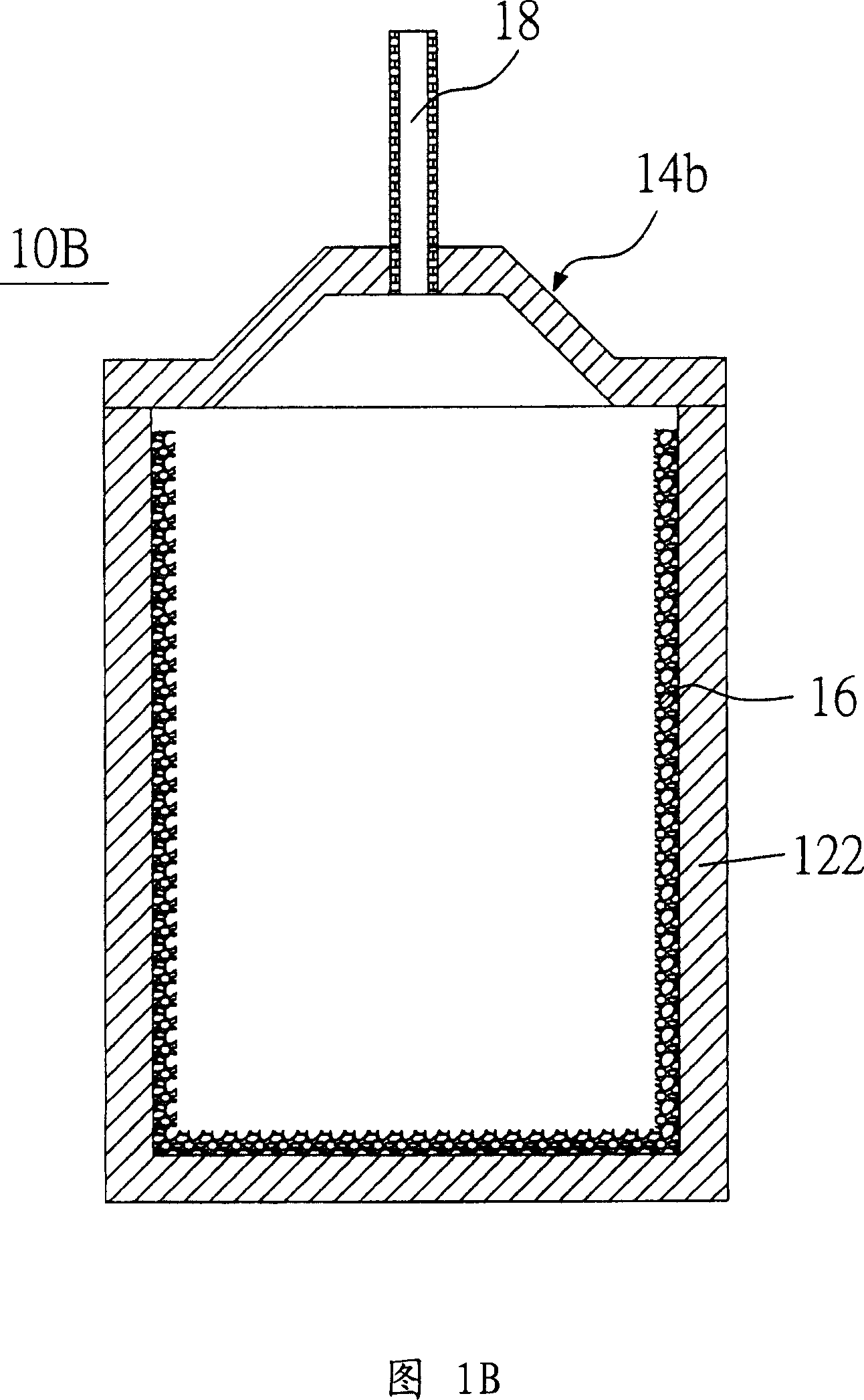

A heat dissipation module and heat pipe technology, applied in indirect heat exchangers, lighting and heating equipment, cooling/ventilation/heating transformation, etc., can solve the problem of increasing the volume of the heat pipe 10B

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

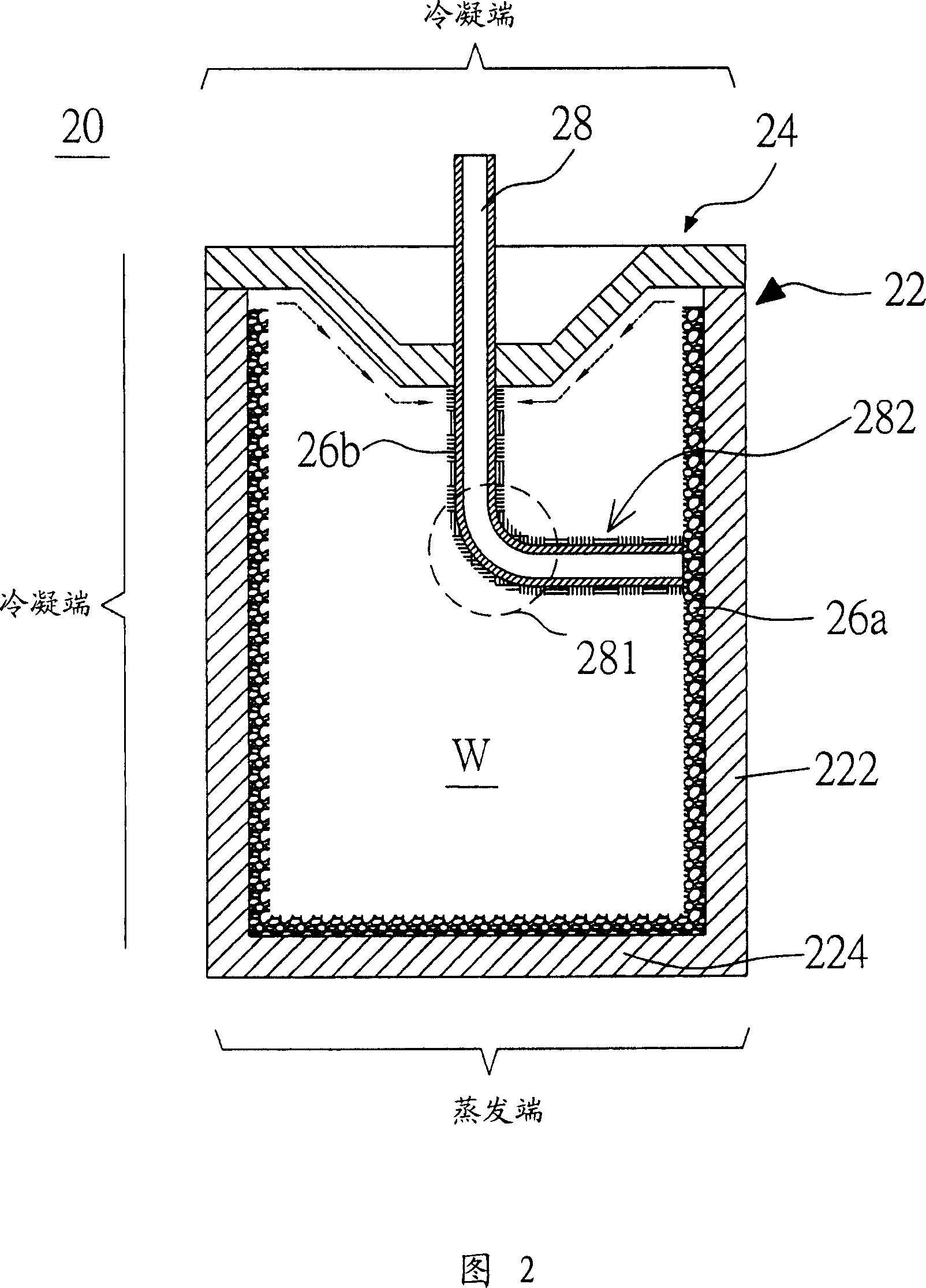

[0042] Embodiments of the heat dissipation module and the heat pipe thereof according to the present invention will be described below with reference to related drawings.

[0043] Please refer to FIG. 2 , which is a schematic diagram of a columnar heat pipe according to a preferred embodiment of the present invention. In FIG. 2 , the columnar heat pipe 20 includes a heat pipe body 22 , an upper cover 24 , a first capillary structure 26 a , a second capillary structure 26 b and a working fluid W filled inside the heat pipe 20 . The heat pipe body 22 has a bottom 224 and a side wall 222 surrounding the bottom 224, and the side wall 222 and the bottom 224 are integrally formed on the heat pipe body 22, or the side wall 222 and the bottom 224 can also be two The components are separated from each other, and the two components are combined to form the heat pipe body 22 .

[0044] On the inner wall of the heat pipe body 22 (that is, on the inner surface of the side wall portion 222...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com