Process for producing inductive coil by printed circuit board

A technology for printed circuit boards and inductance coils, which is used in the assembly of printed circuits with electrical components, coil manufacturing, and signal inductance without a magnetic core. It can solve the problems of cumbersome processes, high costs, and large differences in inductance , to achieve uniform inductance, improve performance, and shorten the production cycle.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

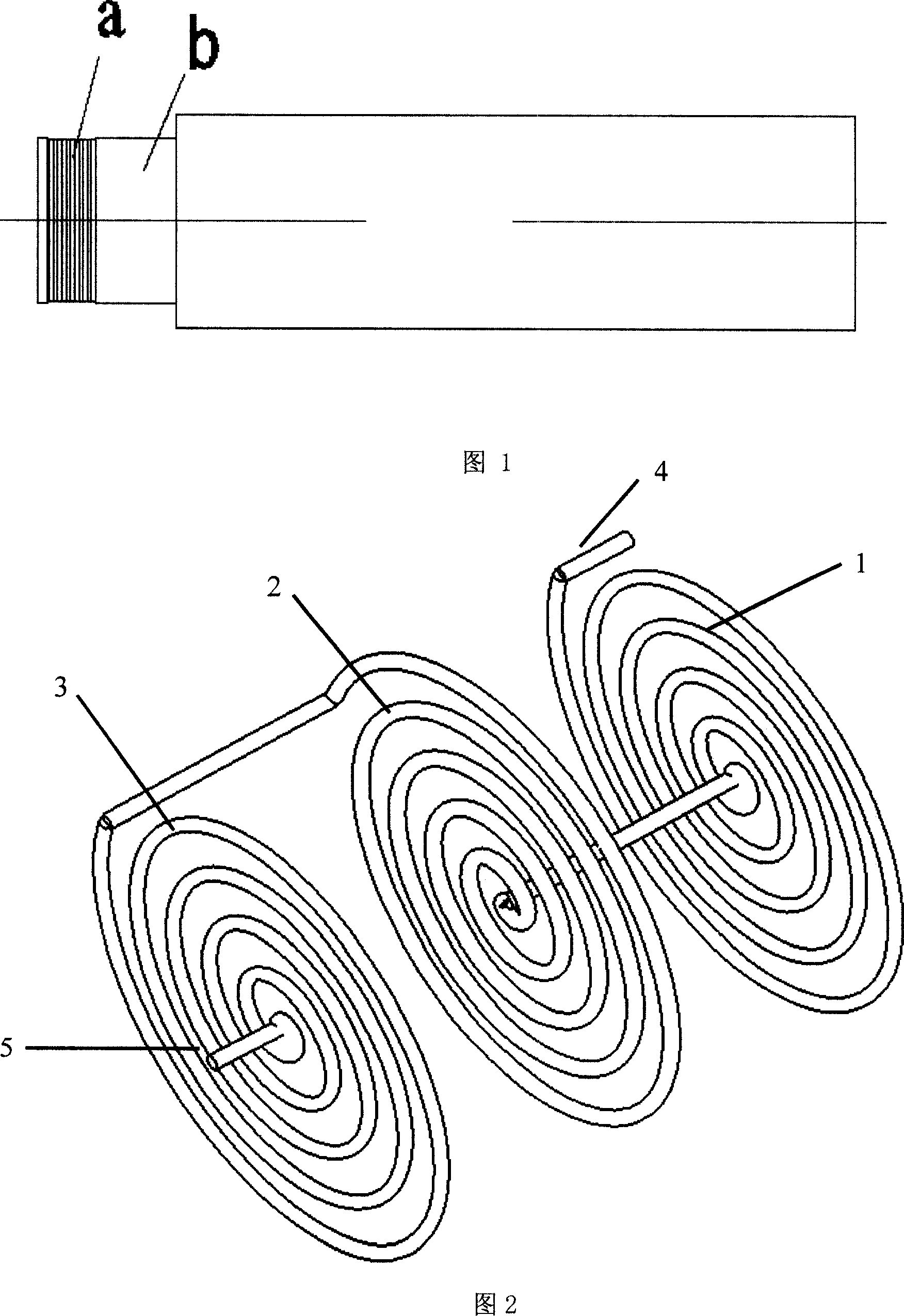

[0017] The inductance coil L is the sensitive element of the eddy current sensor, and its performance parameters directly affect the static and dynamic performance of the eddy current sensor. As shown in Figure 1, it is an inductance coil of a traditional eddy current sensor. This kind of inductance coil is troublesome to wind, and the inductance of the processed inductance coil is not uniform. Make the inductance coil on the printed circuit board, first design a multi-layer circuit board, and design a spiral coil on each layer, and design the number of turns of the coil according to the different requirements for the inductance of the inductance coil and wire size. The two adjacent layers of coils on the circuit board are connected to each other through buried holes and through holes on the printed circuit board. The winding direction of the adjacent two layers of coils is shown in Figure 2. The first layer of coils 1 is clockwise from outside to inside. Winding, when windin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com