Polyester resin compositions with reduced emission of volatile organic compounds

A resin composition, the technology of the composition, applied in the field of low profile additives, low VOC products and parts, A-type SMC mixture, unsaturated polyester field, can solve the problem of unable to reduce VOC emissions and so on

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

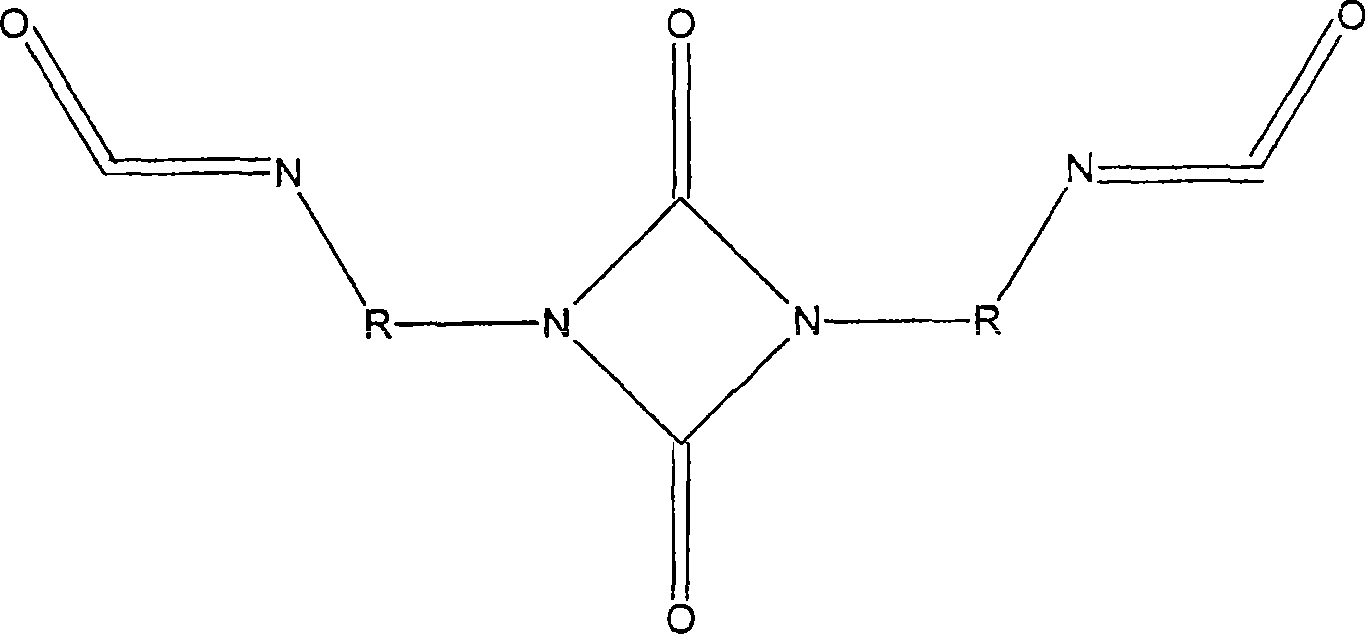

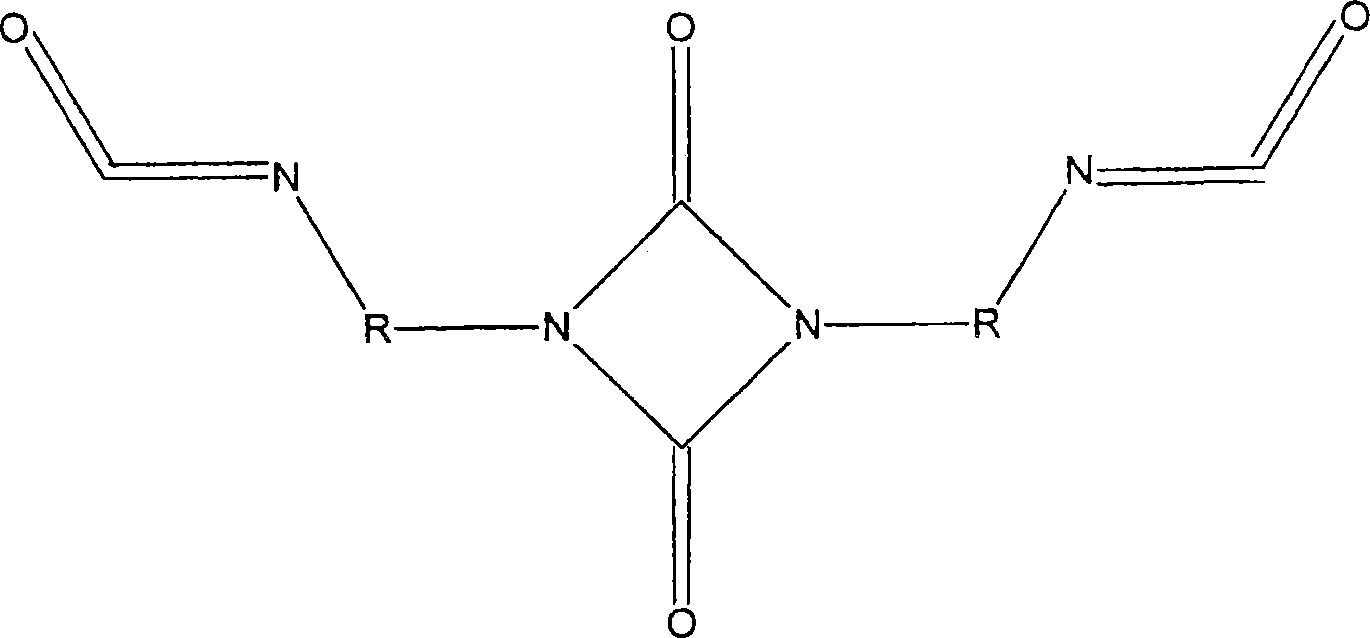

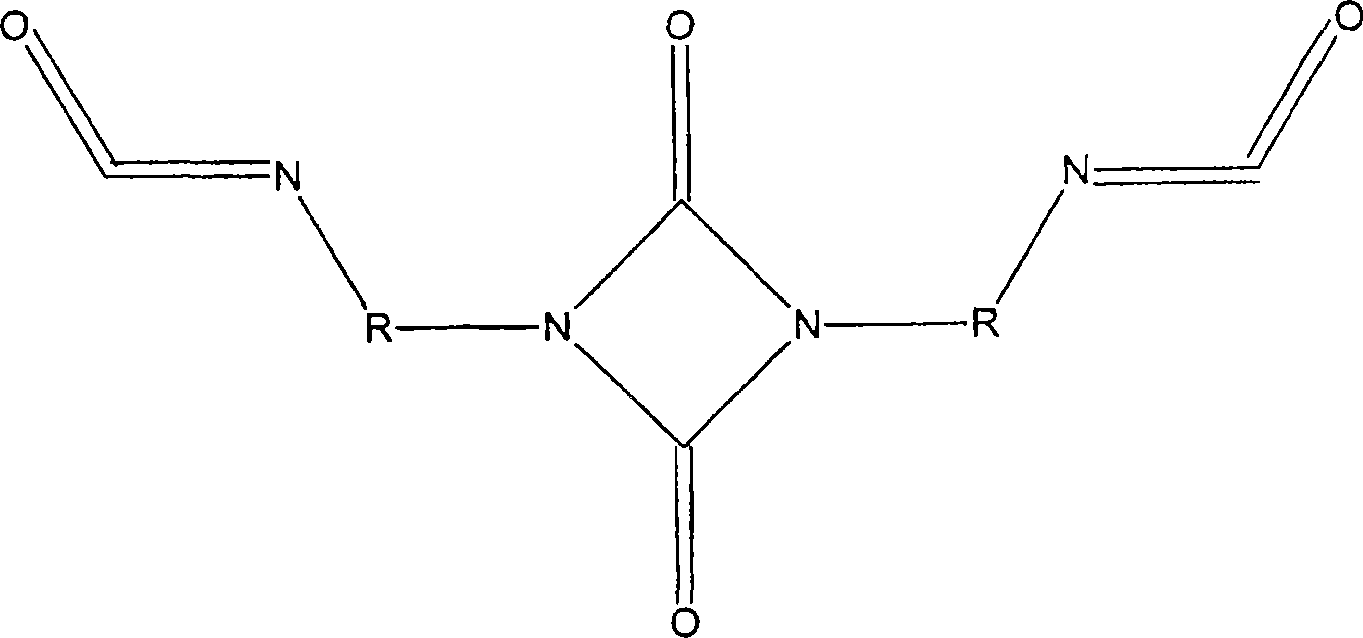

Method used

Image

Examples

Embodiment 1

[0098] Example 1) SMC with LP-polyester modified by Desmodur TT-G, based on 0.9 parts Trigonox 117 and tempered board (190°C, 30 minutes)

[0099] Headspace measurement conditions:

[0100] Sample size: 0.5×0.5cm

[0101] Sample mass: 300mg

[0102] Number of samples measured: 3

[0103] Temper the SMC board at 190°C for 30 minutes

[0104] Prepare various SMC compositions with different uretdione component contents according to the components shown in Table 1, just adopt the amount of uretdione component in the preparation process of LPA-A component to make the urea in the SMC composition The diketone content reached the expected value.

[0105] table 3:

[0106] Desmodur TT

[0107] 3 shows that tempering reduces the concentration of styrene below the detection limit. If 0.4 or 0.5 part of Desmodur TT-G is incorporated into the LP-polyester, so is ethylhexanol. Because of the high vapor pressure, the concentrations of tert-butanol and acetone are signifi...

Embodiment 2

[0108] Example 2) Desmodur TT-G is added to the SMC of the formulation as a separate component, based on 0.9 Part Trigonox 117 and tempered plate (19°C, 30 minutes)

[0109] Headspace test conditions such as embodiment 1

[0110] Table 4:

[0111] Desmodur TT

[0112] From the above results it is known that the addition of Desmodur TT-G (as a separate component) to the SMC formulation results in less reduction in ethyl hexanol. Therefore, it is even more effective to incorporate Desmodur TT into the LP-Polyester.

PUM

| Property | Measurement | Unit |

|---|---|---|

| shrinkage | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com