Feed apparatus for dry desulfurizing digester

A feeding device, dry desulfurization technology, applied in separation methods, chemical instruments and methods, dispersed particle separation, etc., can solve problems such as non-normal operation, numerical differences, affecting the digestive system, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

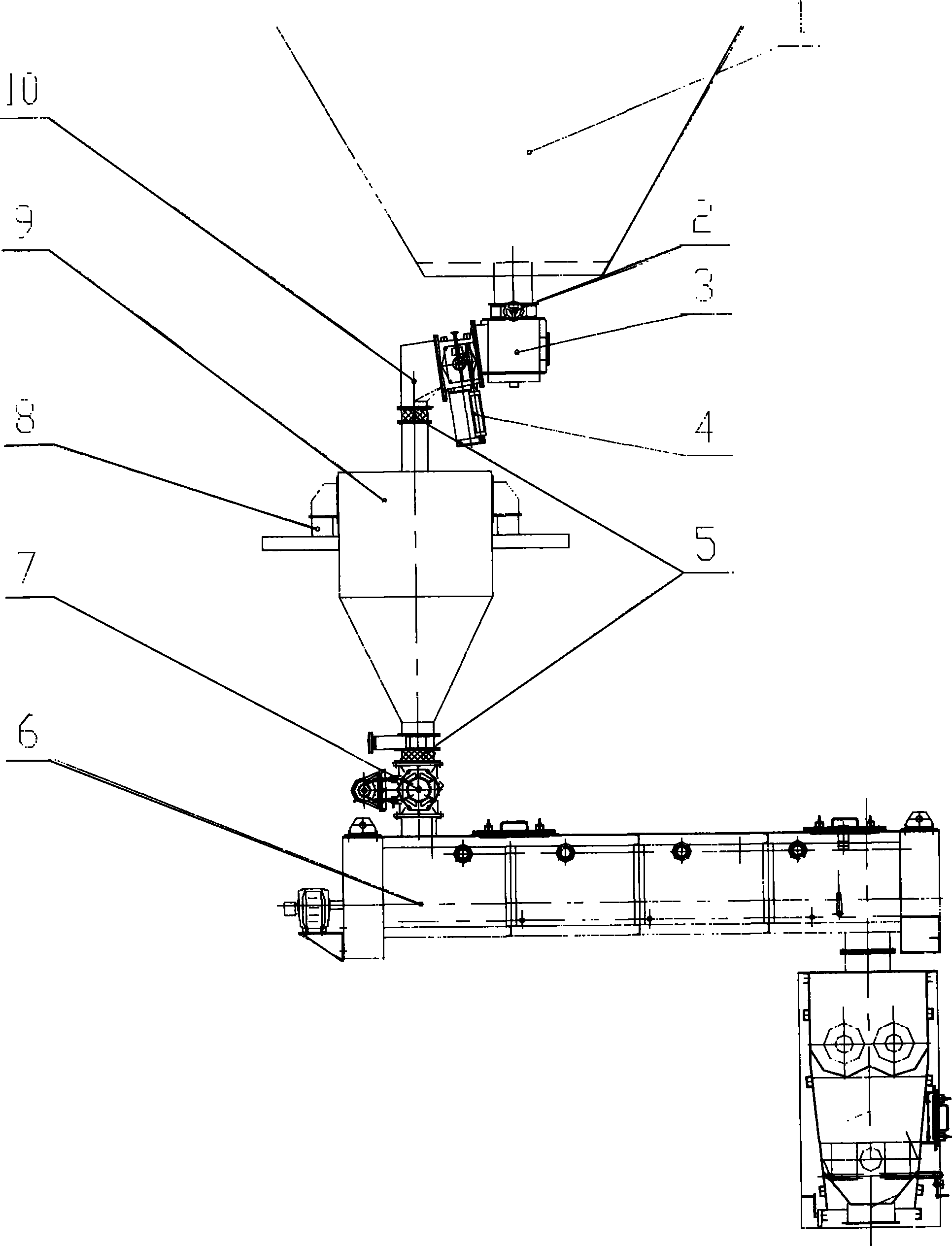

[0010] A feeding device for a dry desulfurization digester shown in the figure is composed of a flapper valve, an aeration box, a material flow control door and a discharge tank, and an intermediate warehouse ( 9), a weighing element (8) is arranged in the intermediate bin (9), and a frequency-modulated rotary feeder (7), a weighing element (8) and a frequency-modulated rotary feeder are installed below the outlet of the intermediate bin (9). The controllers (7) are respectively connected to the controller through cables; the connection between the intermediate bin (9) and the discharge tank (10) and the frequency-modulated rotary feeder (7) is connected through a flexible expansion joint (5).

[0011] When the digester system starts, the intermediate bin (9) starts to feed, and the calcium oxide passes through the bin (1) through the flapper valve (2), the aeration box (3), the material flow control door (4), and the discharge tank (10 ), enter the intermediate warehouse (9)....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com