Chlorine gas metering and leading-in device in phenylethene thermostable resin chloridization process

A high-temperature-resistant resin and styrene-based technology, applied in the field of chlorine gas metering and introducing devices, can solve the problems of complicated pipeline connections, complicated operations, and many storage tanks, and achieve the effects of improving physical and chemical performance indicators, wide application, and precise control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

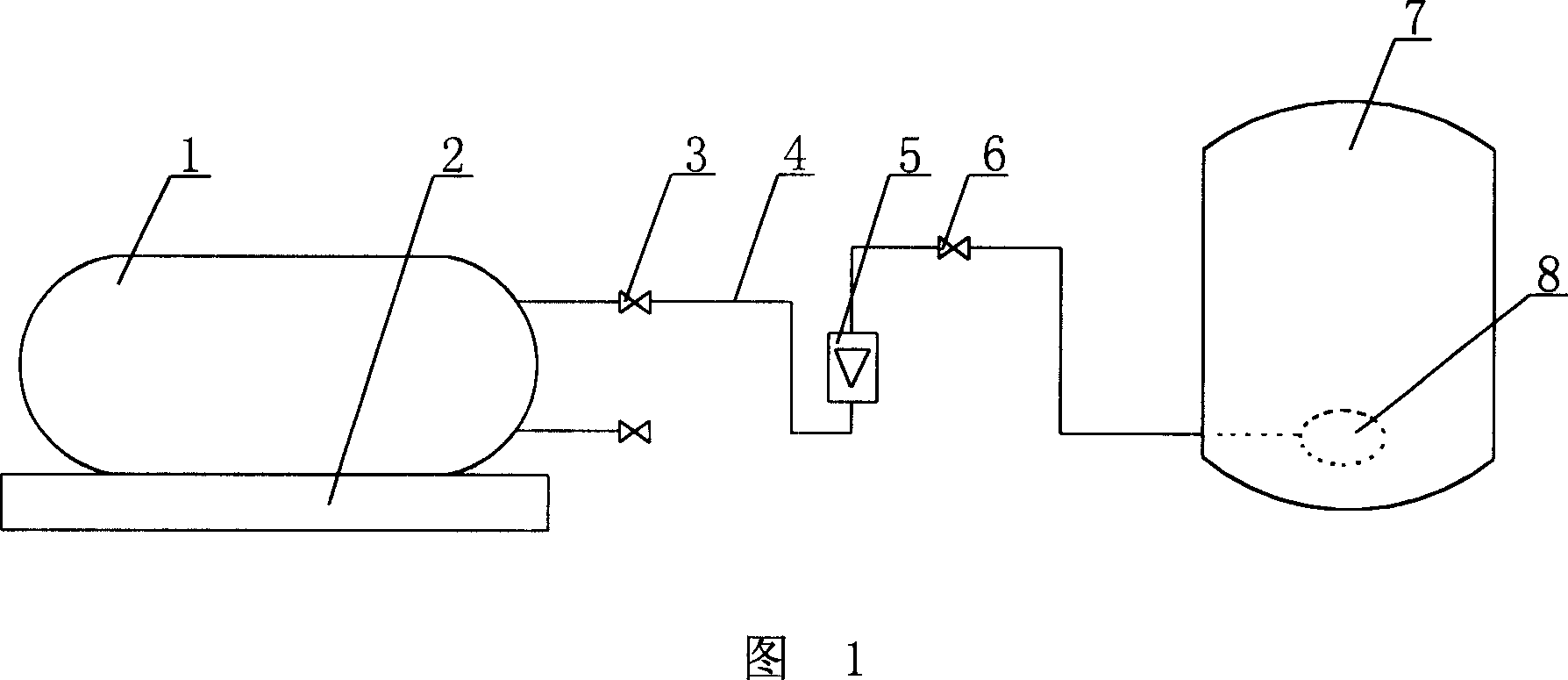

[0020] Embodiment 1 As shown in Figure 1, the chlorine gas metering and introducing device in the styrene-based high temperature resistant resin chlorination process consists of chlorine bottle 1, chlorine bottle continuous metering electronic scale 2, gas chlorine outlet valve 3, chlorine gas pipe 4, glass rotor flow rate Meter 5, chlorine gas regulating valve 6 and chlorine gas distributor 7, chlorine bottle 1 is placed on electronic scale 2, one end of chlorine gas pipe 4 is connected to chlorine bottle and then connected to gas chlorine outlet valve 3, glass rotameter 5, gas chlorine Regulating valve 6, the other end of which is installed with a chlorine gas distributor 8 extending into the styrene-based high-temperature-resistant resin chlorination reaction kettle 7, the chlorine gas pipe is inserted from the still body of the reaction kettle, and the chlorine gas distributor 8 is distributed with porous annular Tube.

[0021] Utilize this chlorine metering introduction d...

Embodiment 2

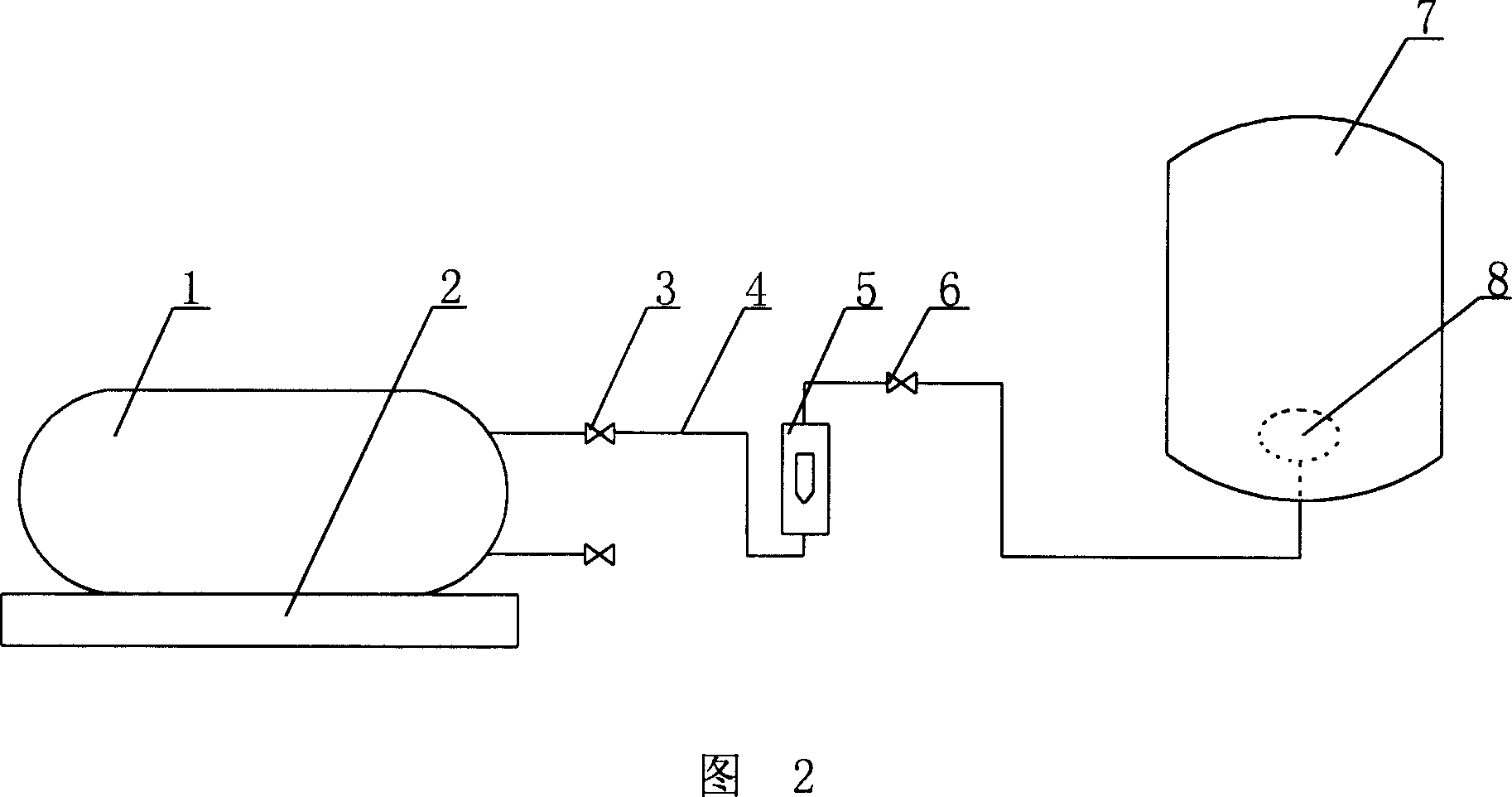

[0022] Embodiment 2 As shown in Figure 2, the chlorine gas metering and introducing device in the styrene-based high temperature resistant resin chlorination process consists of chlorine bottle 1, chlorine bottle continuous metering electronic spring scale 2, gas chlorine outlet valve 3, chlorine gas pipe 4, metal rotor flow rate Meter 5, chlorine gas regulating valve 6 and chlorine gas distributor 7. The chlorine bottle 1 is placed on the electronic scale 2. One end of the chlorine gas pipe 4 is connected to the chlorine bottle and connected to the chlorine gas outlet valve 3, the glass rotameter 5 and the gas chlorine regulator in turn. Valve 6, the other end of which is equipped with a chlorine gas distributor 8 extending into the styrene-based high-temperature-resistant resin chlorination reaction kettle 7, the chlorine gas pipe is inserted from the bottom of the reaction kettle, and the chlorine gas distributor 8 is a circular pipe with holes .

[0023] Utilize this chlor...

Embodiment 3

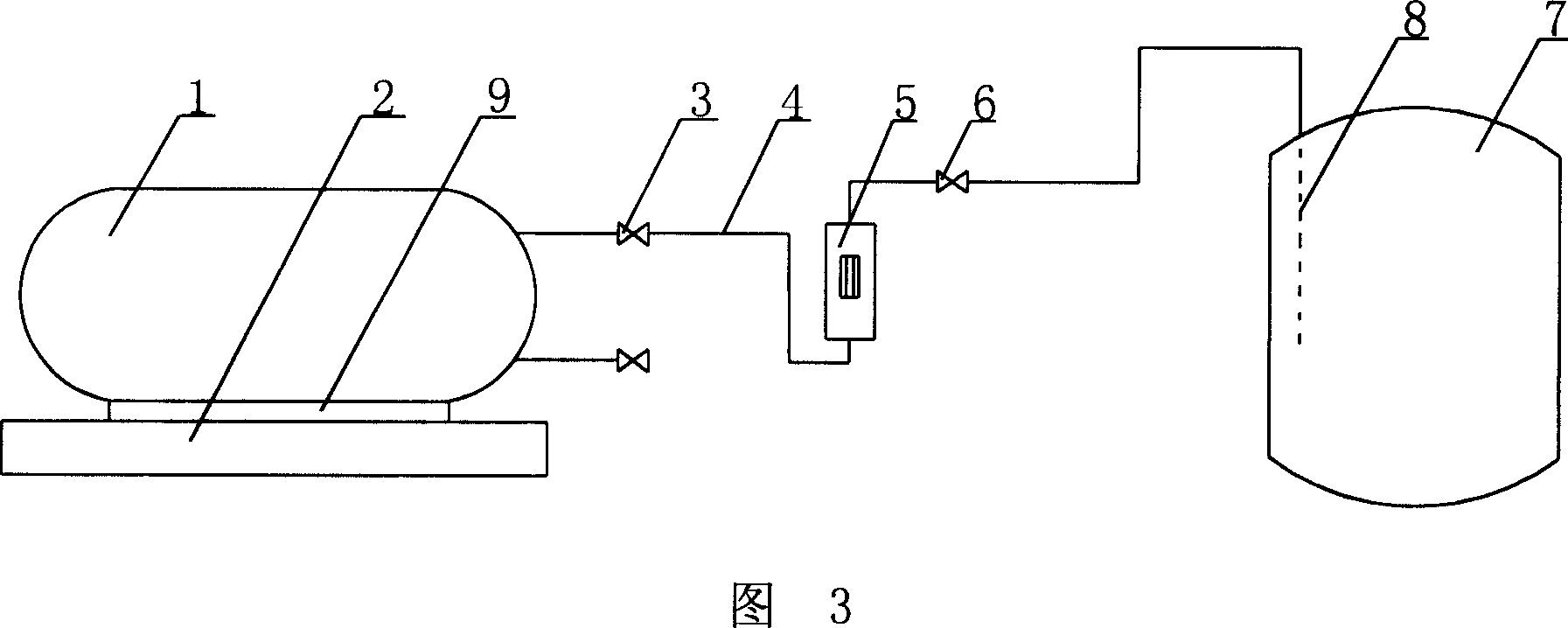

[0024] Embodiment 3 As shown in Figure 3, the chlorine gas metering and introducing device in the styrene-based high-temperature-resistant resin chlorination process consists of a chlorine bottle 1, a chlorine bottle continuous metering mechanical scale 2, a gas chlorine outlet valve 3, a chlorine gas pipe 4, and an orifice flow rate Meter 5, gas chlorine regulating valve 6 and chlorine gas distributor 7 are composed of, an electric heating device 9 is also arranged under the chlorine bottle 1, the chlorine bottle and the heating device are placed on the electronic scale 2, and one end of the chlorine gas pipe 4 is connected to the chlorine bottle and connected in sequence The gas chlorine outlet valve 3, the orifice flowmeter 5 and the gas chlorine regulating valve 6 are equipped with a chlorine gas distributor 8 extending into the styrene series high temperature resistant resin chlorination reaction kettle 7, and the chlorine gas pipe is connected from the top of the reaction ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com