Stationary electrolyte concentration cell for measuring sulfur content of molten iron

A concentration-difference battery and solid electrolyte technology, applied in the field of electrochemistry, can solve problems such as insufficiency, achieve the effects of rapid pretreatment, reduce production costs, and improve desulfurization efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

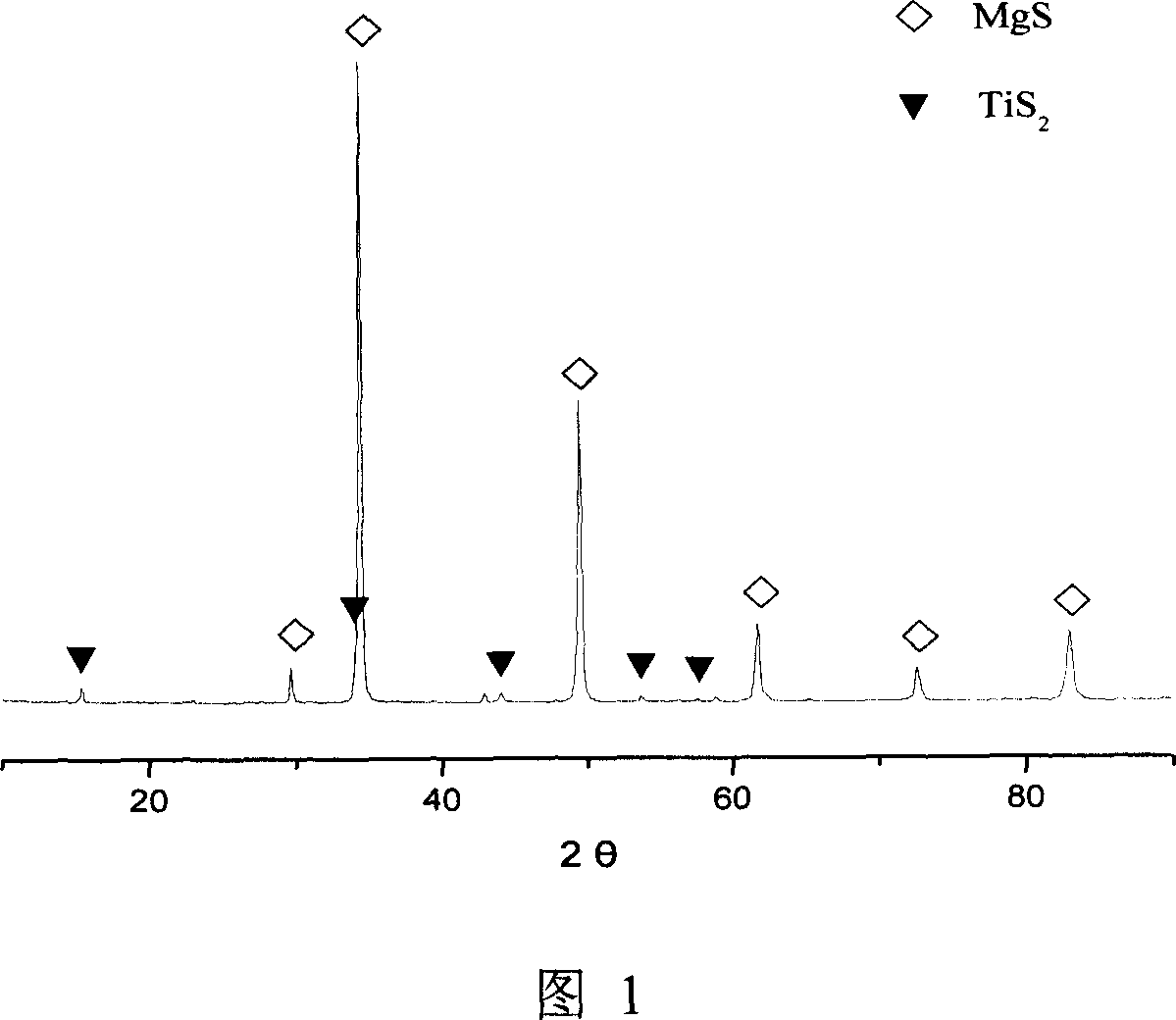

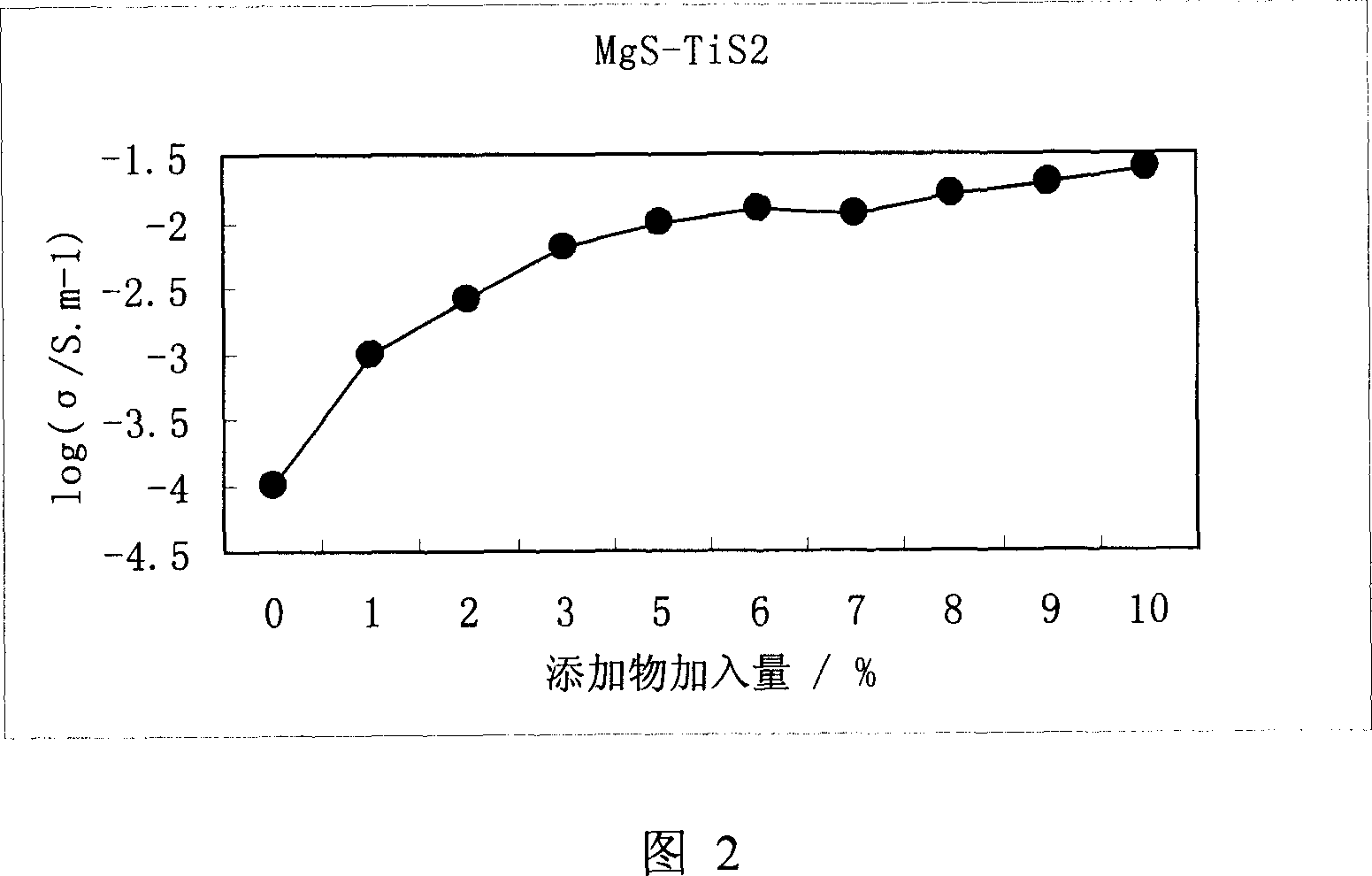

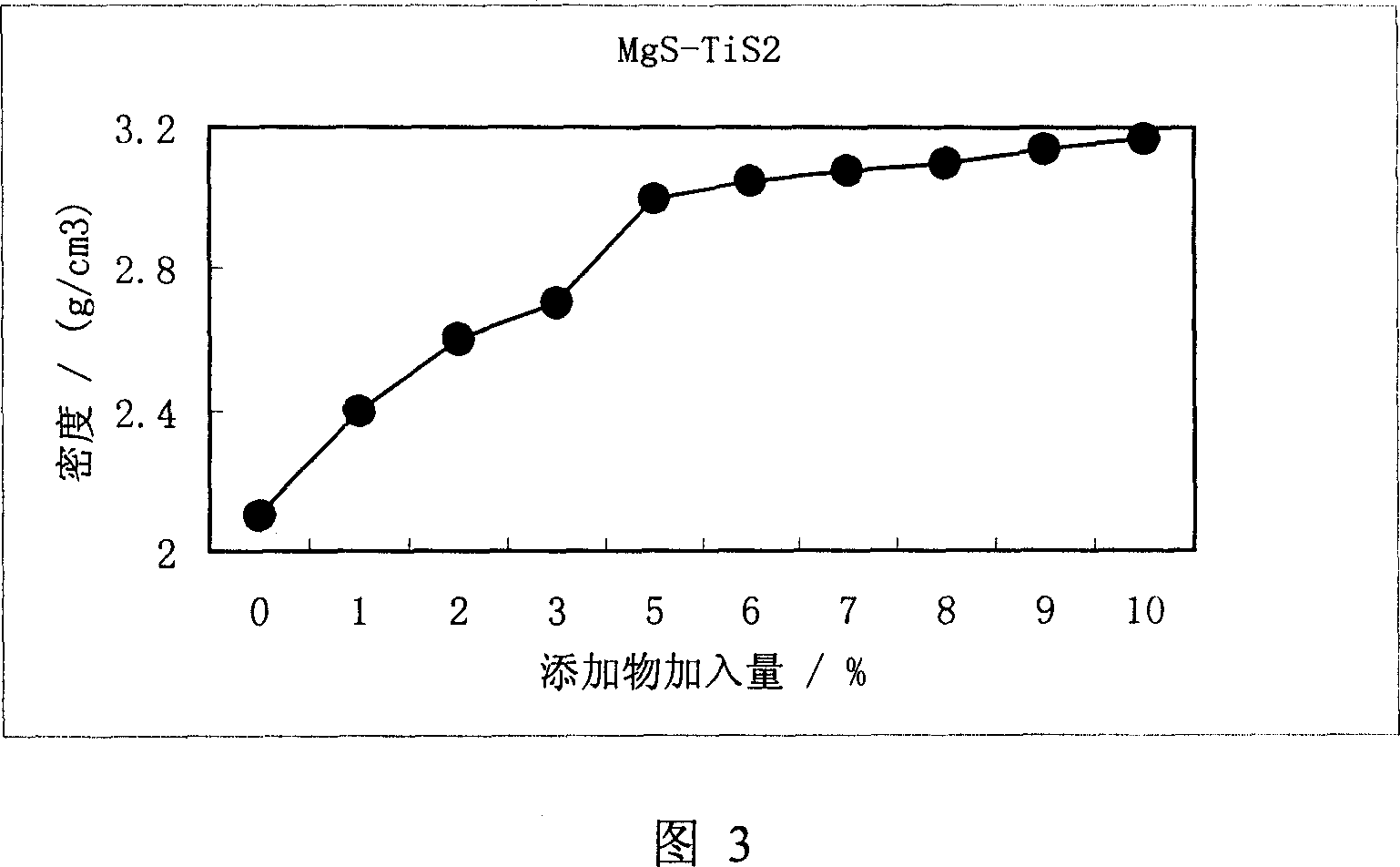

[0024] The main index affecting the performance of solid electrolytes is the ionic conductivity of solid electrolytes. In addition, the densification degree of the solid electrolyte itself also has an important influence on the stability and reproducibility of the test electromotive force signal. The present invention chooses MgS-TiS 2 as a solid electrolyte. Its ratio is shown in Table 1,

[0025] solid electrolyte

components

Proportion

MgS-TiS 2

MGS

100

99.0

97.0

95.0

93.0

91

90

88

85

TiS 2

0

1.0

3.0

5.0

7.0

9.0

10.0

12

15

[0026] Solid Electrolyte MgS-TiS 2 Experimental process: Weigh the synthesized sulfides according to the proportion shown in Table 1, and mix them evenly. Press the mixed sulfide powder into a sample of 5×10mm at a pressure of 200MPa. Put the pressed solid electr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com