Laser processing method

A laser processing method and technology for processing objects, applied in metal processing, stone processing equipment, laser welding equipment, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

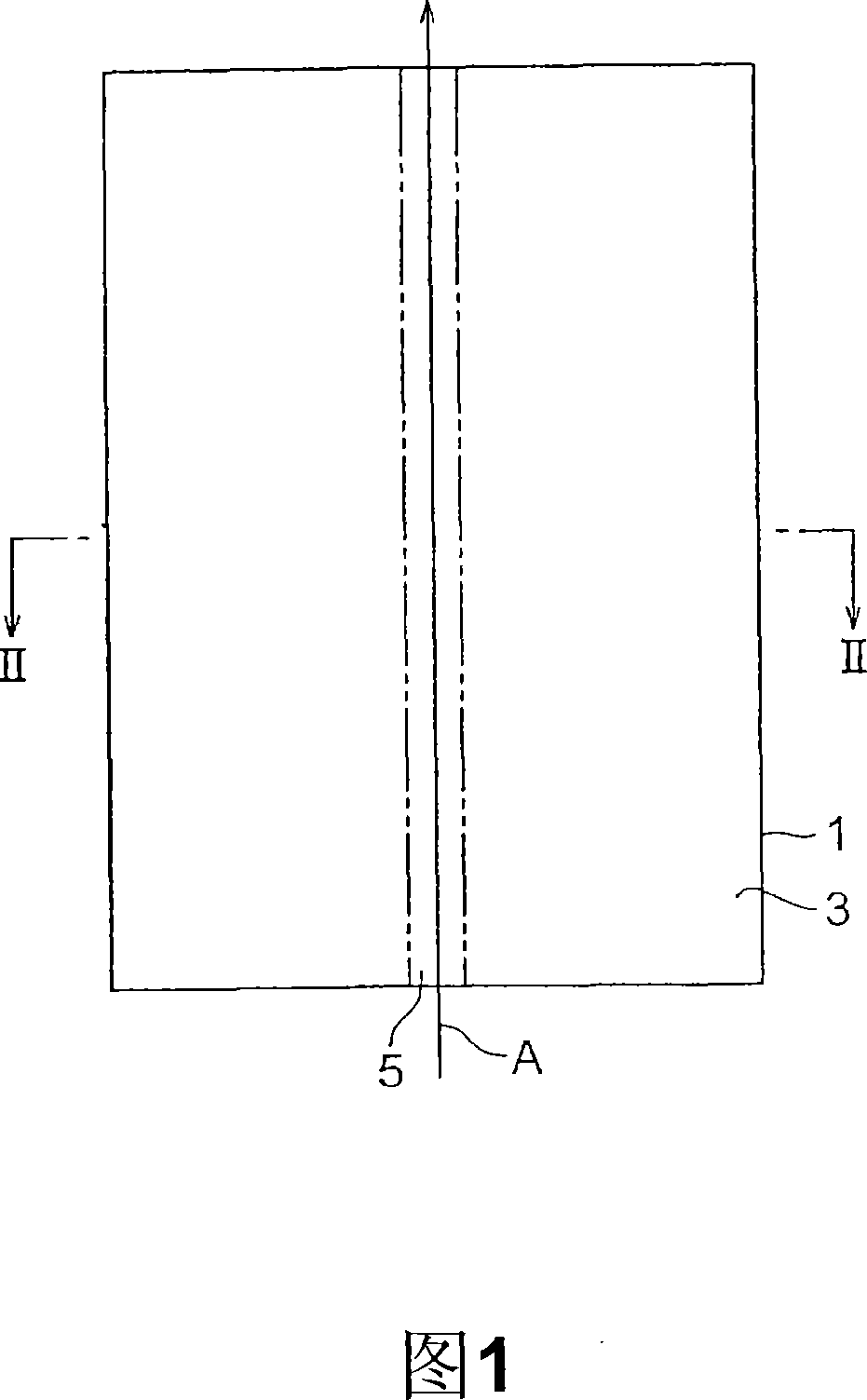

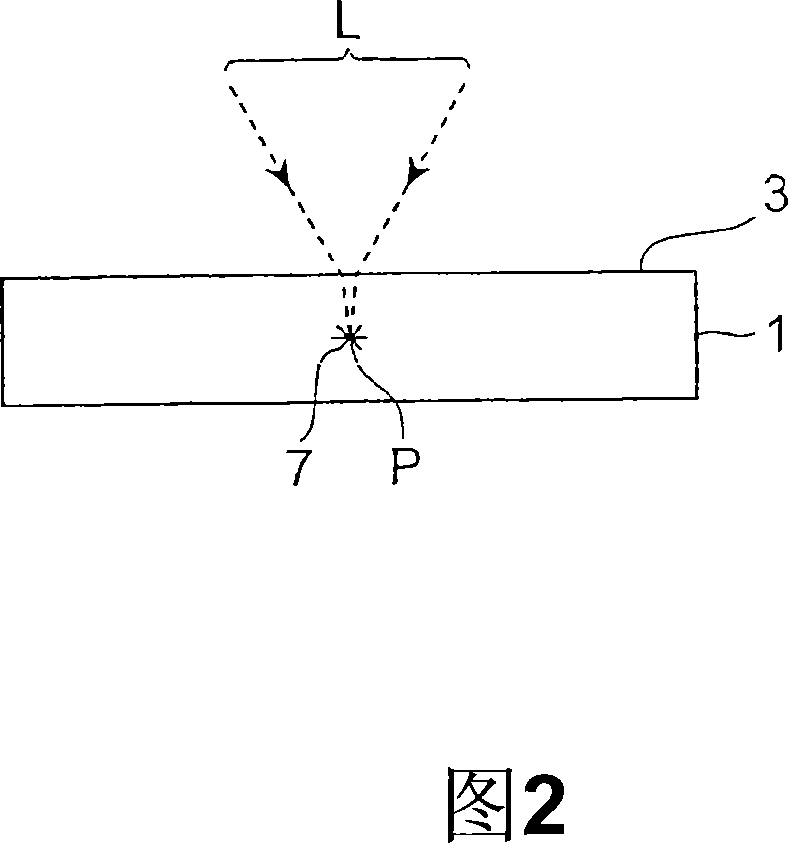

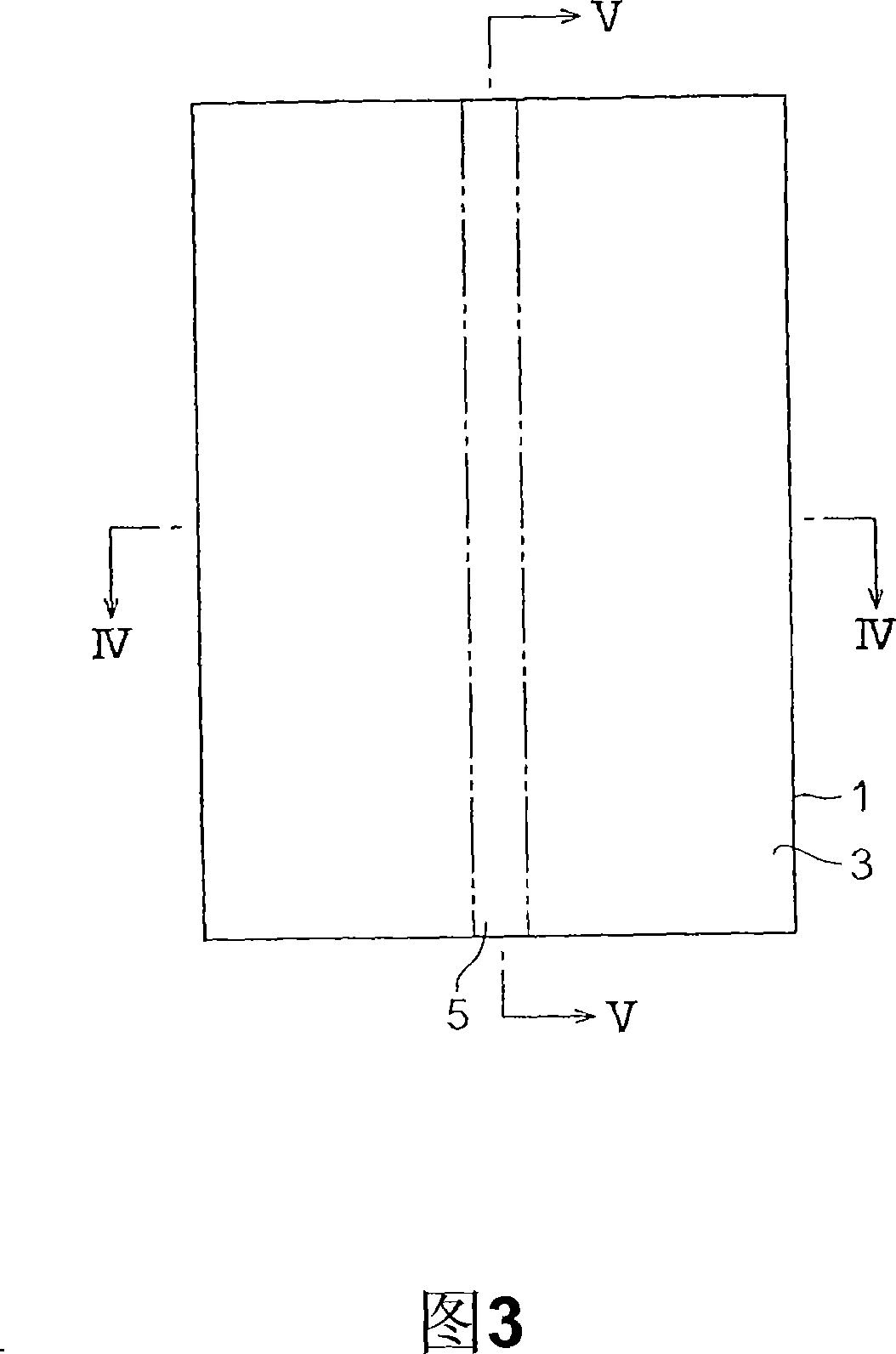

[0066] Hereinafter, preferred embodiments of the present invention will be described in detail with reference to the drawings. In the laser processing method of the present embodiment, a phenomenon called multiphoton absorption is utilized in order to form a modified region inside the object to be processed. Therefore, first, a laser processing method for forming a modified region using multiphoton absorption will be described.

[0067] The band gap (band gap) E G When it is still young, it becomes optically transparent. Therefore, the condition for absorption on the material is hv>E G . However, even if it is optically transparent, if the intensity of the laser is increased very much, then nhv>E G Absorption occurs on the material under the conditions (n=2, 3, 4, ...). This phenomenon is called multiphoton absorption. In the case of pulsed waves, the intensity of the laser is determined by the peak power density (W / cm 2 ) determined, for example, at a peak power densit...

PUM

| Property | Measurement | Unit |

|---|---|---|

| wavelength | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| transmittivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com