Surface self-cleaning daily-use bionic ceramic production method

The technology of a structural surface and a manufacturing method is applied in the field of the manufacture of self-cleaning daily-use ceramics with a bionic structural surface, which can solve the problems of easy dirtying, few consumers adopt, and difficult to clean, and achieve the effect of prolonging the service life.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

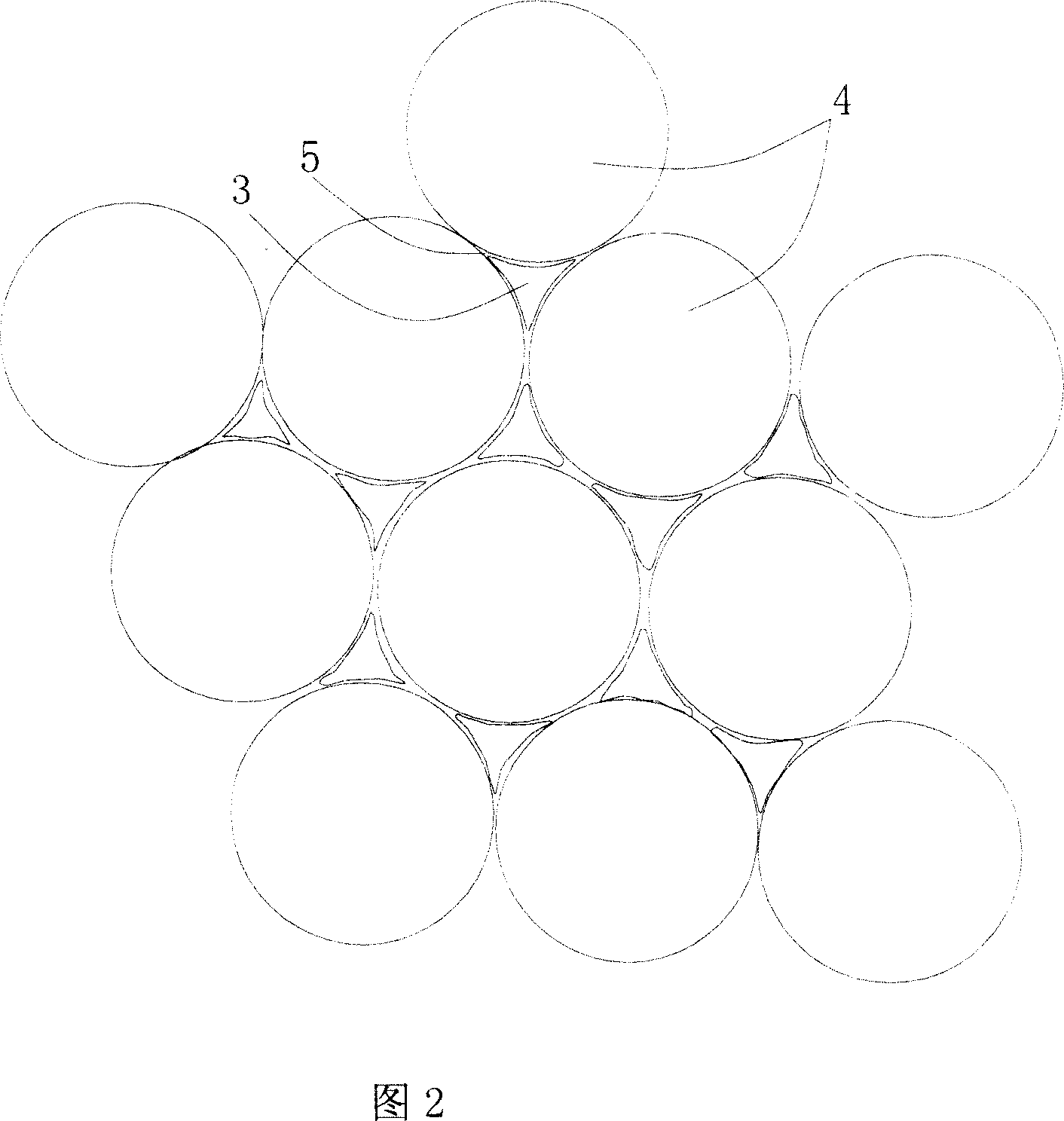

[0014] Please refer to shown in Fig. 2, below in conjunction with embodiment will illustrate the manufacture method of a kind of bionic structure surface self-cleaning household ceramics adopted by the present invention, its technological process:

[0015] The first step, ceramic products: mix various ingredients such as kaolin, talc, alumina and bluestone in a certain proportion to form a mixture, and then uniformly mix plastic additives and ceramic carriers with the mixture to form a batch. The batch material is extruded and dried to form a ceramic green body, and finally the ceramic green body is heated according to different firing temperatures to make it fired into ceramic products;

[0016] The second step, ceramic products and coating: while glazing the ceramic surface, the arrayed carbon nanotube film is covered on the surface of the fired ceramic product by using the sol, gel method and dipping and pulling method;

[0017] The third step, the firing of the coated prod...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com