Enzyme catalysis method for continuous synthesis of lauroyl maltose under organic phase

A technology of lauric acid ester and maltose, applied in the field of food biochemical industry, can solve the problems of batch production not suitable for large-scale industrial production, complicated separation work, slow reaction rate, etc., and achieves mild conditions, simple separation and purification, and increased yield Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

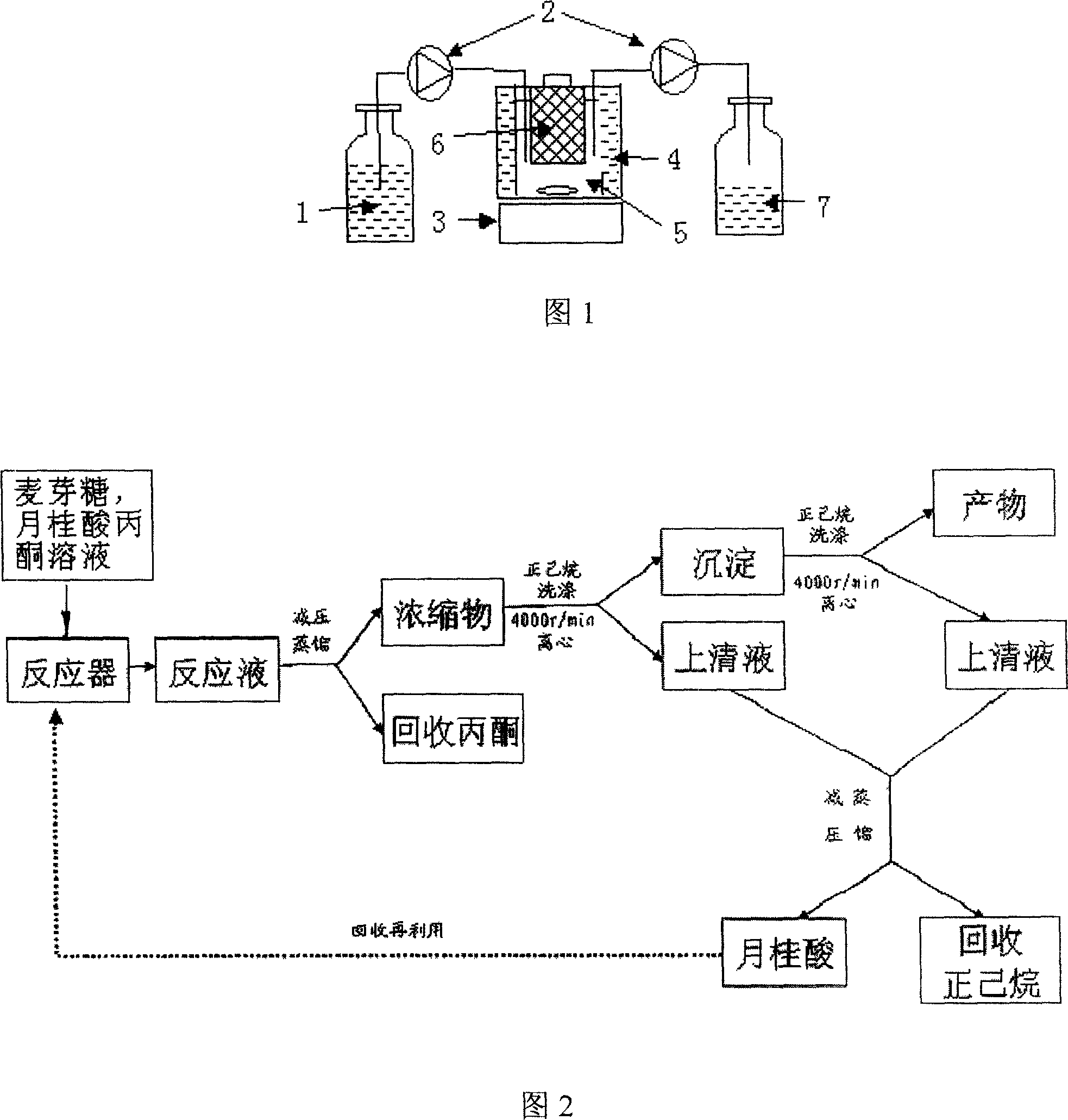

Method used

Image

Examples

Embodiment 1

[0035] At the beginning of the reaction, the concentration of maltose was 25mmol / L (2.125g), 250ml of 100mmol / L acetone laurate solution, 20g / L lipase, and 8g / L maltose was added to the reactor every day after the reaction, 100mmol / L. L lauric acid acetone solution enters the reactor at a flow rate of 0.36 ml / min, and reacts for 10 days. The yield and the amount of product obtained after separation and purification are shown in Table 1.

[0036] Table 1

[0037] Days

Embodiment 2

[0039]At the beginning of the reaction, the concentration of maltose was 50mmol / L (4.275g), 250ml of 200mmol / L lauric acid acetone solution, 40g / L lipase, and 12g / L maltose and 200mmol / L lauric acid were added every day in the reaction. The acetone solution enters the reactor at a flow rate of 0.2ml / min and reacts for 10 days. The yield and the amount of product obtained after separation and purification are shown in Table 2.

[0040] Table 2

[0041] Days

Embodiment 3

[0043] At the beginning of the reaction, the concentration of maltose was 100mmol / L, 250ml of 300mmol / L lauric acid acetone solution, and 60g / L lipase were added to the reactor. After that, 16g / L maltose was added every day in the reaction, and 300mmol / L lauric acid acetone solution was 0.15 The flow rate of ml / min enters the reactor and reacts for 10 days. The yield and the product volume obtained after separation and purification are shown in Table 3.

[0044] table 3

[0045] Days

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com