Composite wood floor

A solid wood composite floor and floor technology, which is applied in the direction of floors, buildings, building structures, etc., can solve the problems of insufficient longitudinal strength, fracture, and easy stress, and achieves low production cost, high efficiency, and strong anti-deformation ability. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

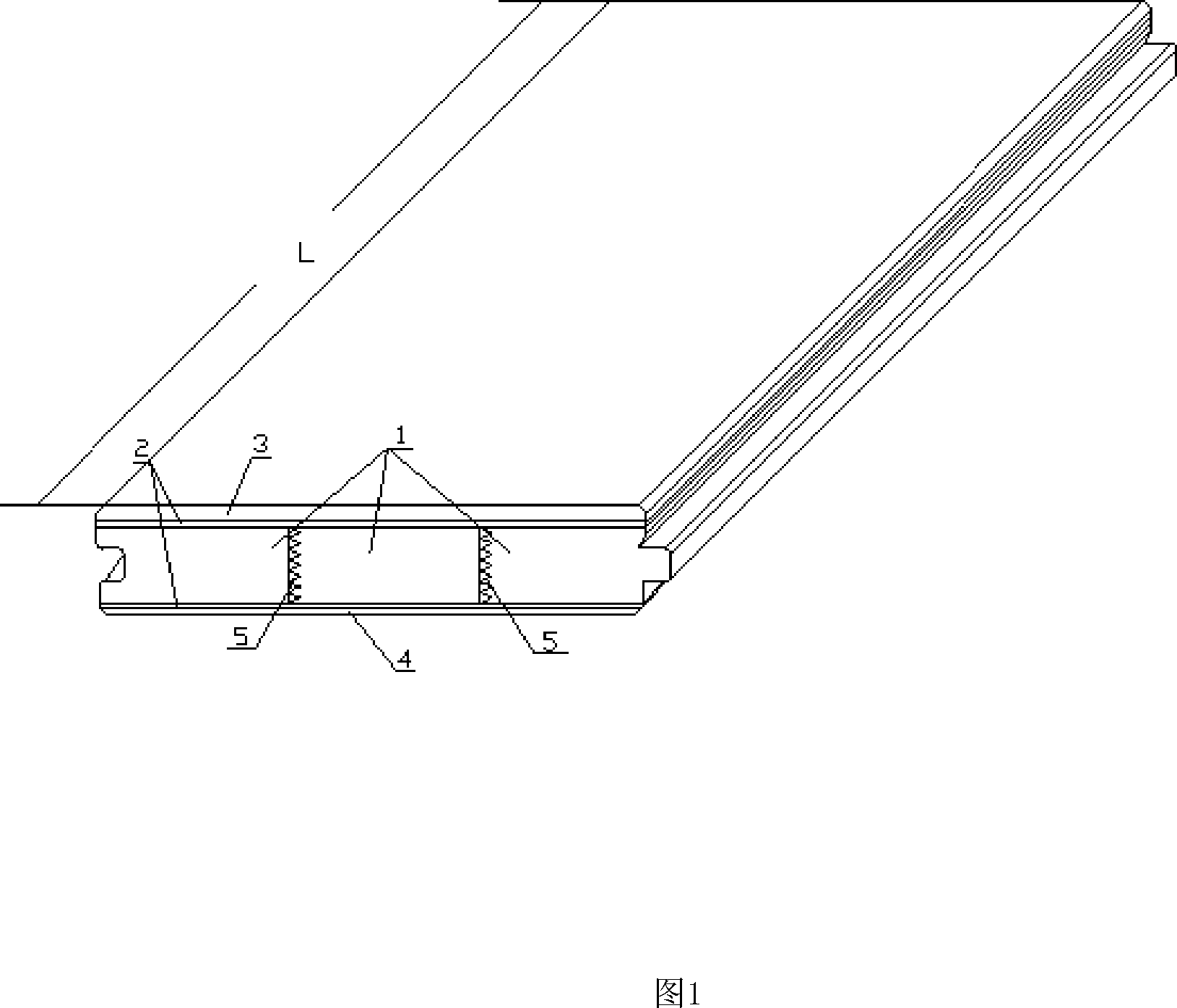

[0011] Embodiment of the present invention: the present invention adopts a five-layer structure including a core layer 1, two balance layers 2, a surface layer 3 and a bottom layer 4, and a core layer 1 is arranged between the two balance layers 2, and a surface layer 3 and a bottom layer 4 are respectively arranged on both sides. Adopt conventional techniques, especially combine mature blockboard technology with solid wood flooring technology, and the five-layer structure of the floor is arranged vertically and horizontally according to the direction of wood fibers. The direction is the same, and the horizontal arrangement means that the direction of the fiber is consistent with the direction of the long side and the short side of the solid wood composite floor, that is, perpendicular to the L direction, and the core layer 1 adopts 2 to 7 whole lengths or connected lengths. It is best when 3 to 5 pieces are used, and one side of the rectangular wooden strip is processed into a...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap