Method of automating a thermographic inspection process

An inspection process and aspect technology, applied in the field of infrared camera and other camera inspection systems, that can solve problems such as errors, inappropriate camera settings, failure to inspect mechanical features, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

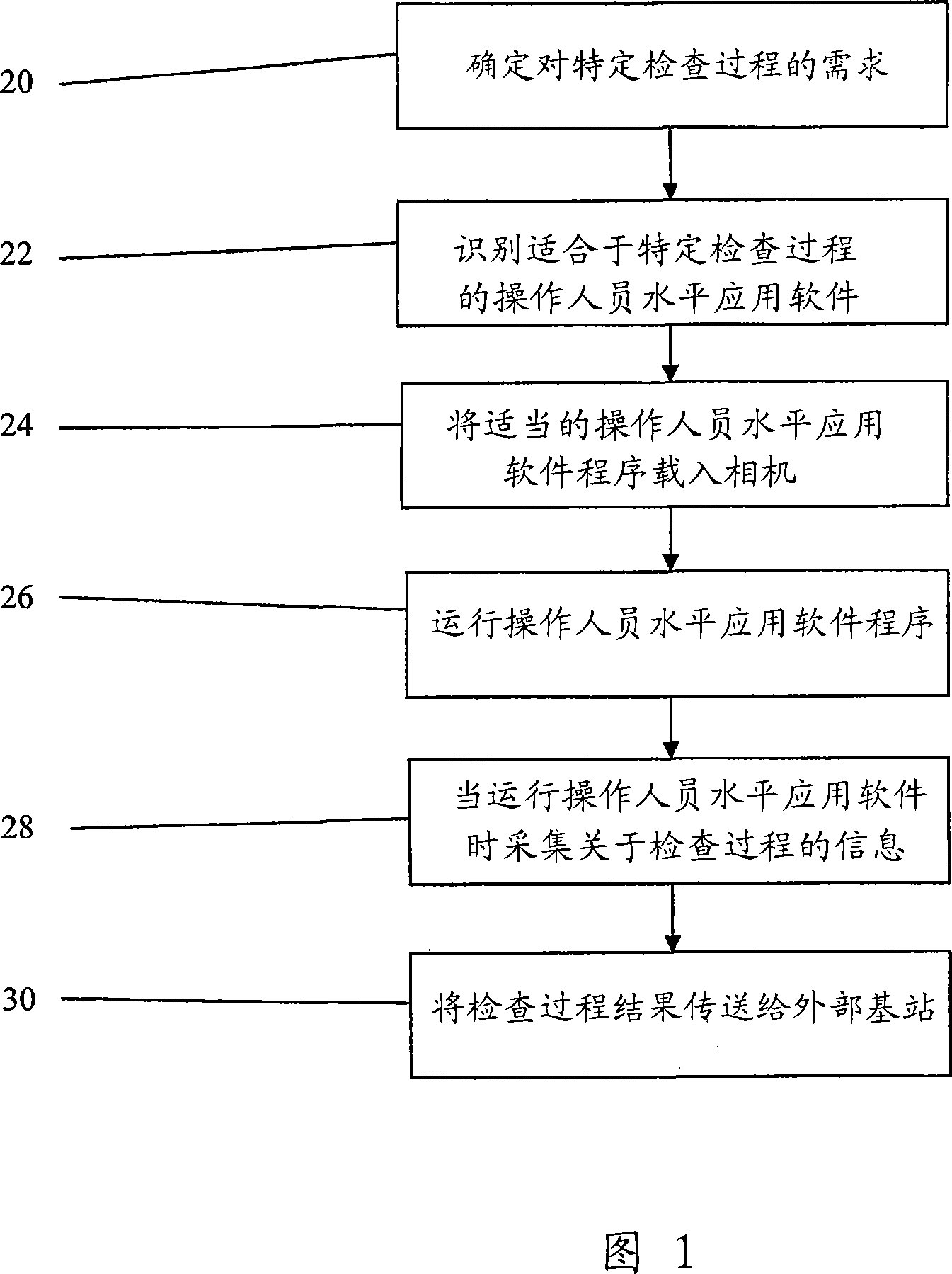

[0021] Automated thermographic inspection processing extends existing technologies for infrared inspection processing. By utilizing automation, less skilled and less trained operators are able to use more complex and capable infrared inspection systems used by inspectors, technicians, security personnel, engineers, and others who rely on infrared imaging , to perform temperature recording or monitoring, or other examinations for discerning, distinguishing, or identifying properties revealed by changes in temperature and / or emissivity in equipment, machinery, animals, humans, or other substances.

[0022] In the most preferred embodiment, the process involves the use of a portable programmable focal plane infrared (IR) camera comprising an uncooled radiative infrared focal plane array, plus a visual camera built into a lightweight, hand-held unit with Built-in data storage memory, liquid crystal display (LCD), or similar display for displaying image data, microprocessor, microp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com