Transporting station and method for transporting fish in a transporting direction, which is transverse to their longitudinal extent, and fish-processing machine having such a transporting station

a transport station and transverse technology, applied in fish processing, butchering, fish arrangement, etc., can solve the problems of insufficient cutting, inability to separate the head from the body without yield loss, and inability to separate the fish lying on the side, so as to prevent the displacement of fish, facilitate the transfer of fish, and improve the effect of orientation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

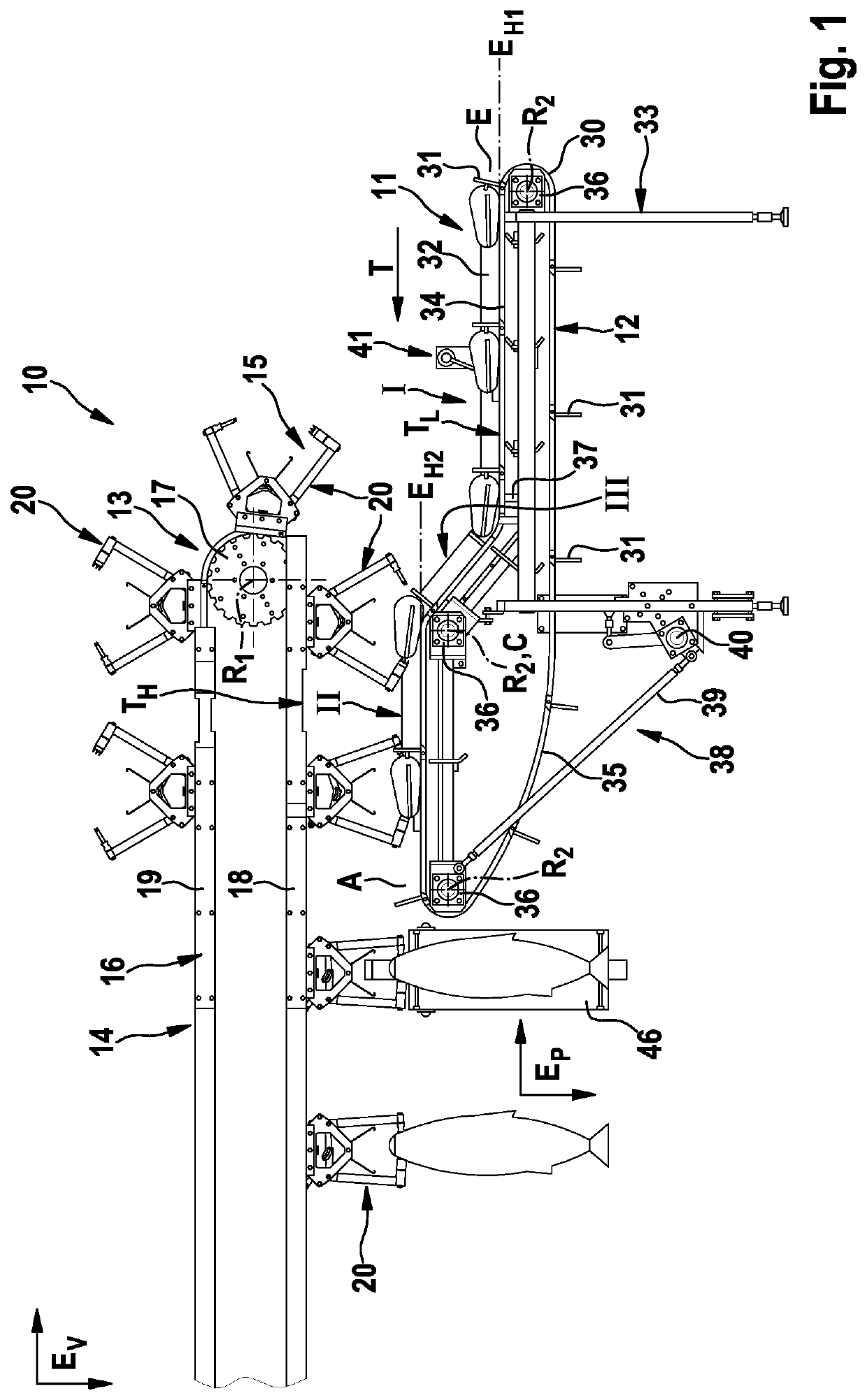

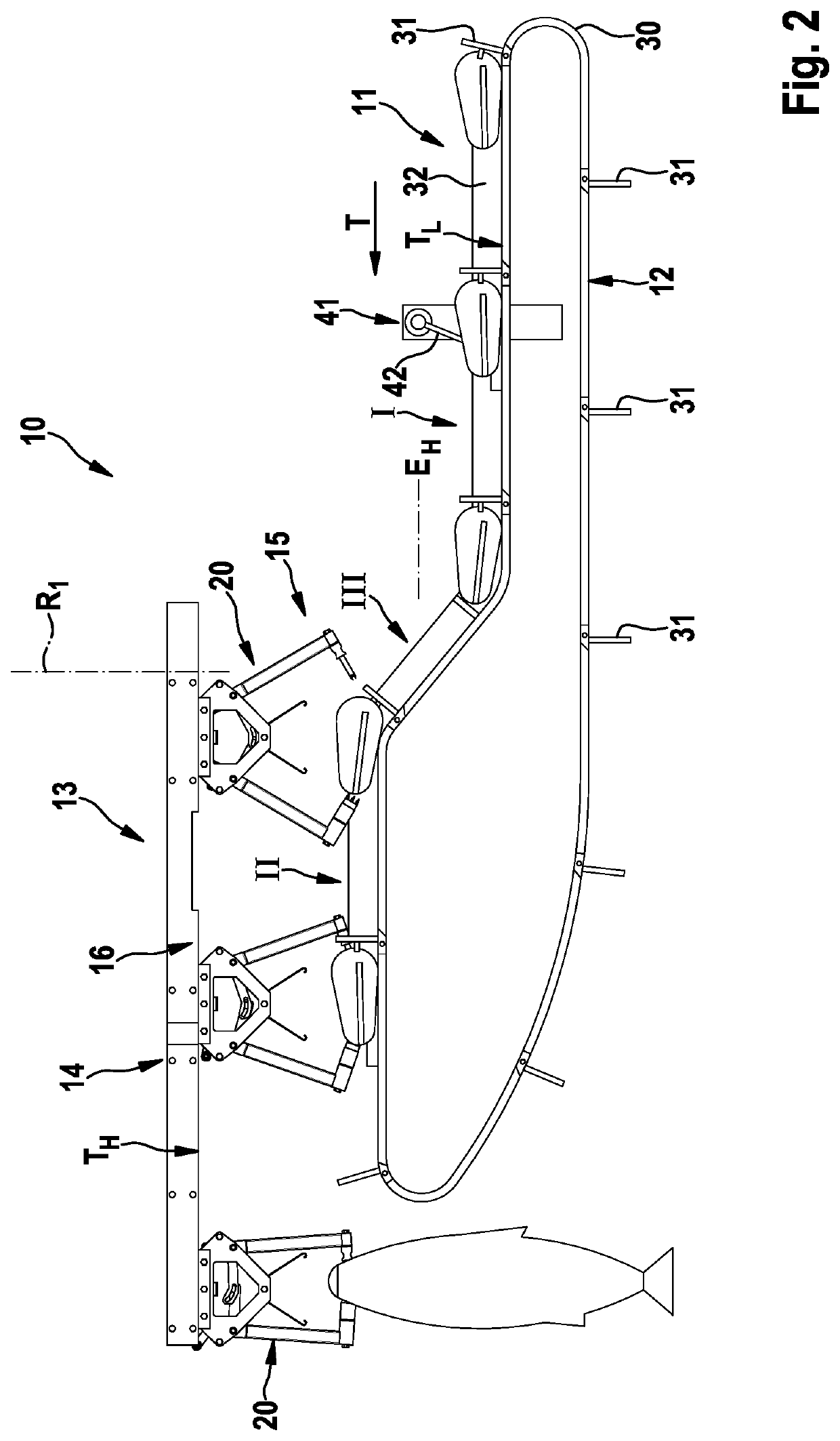

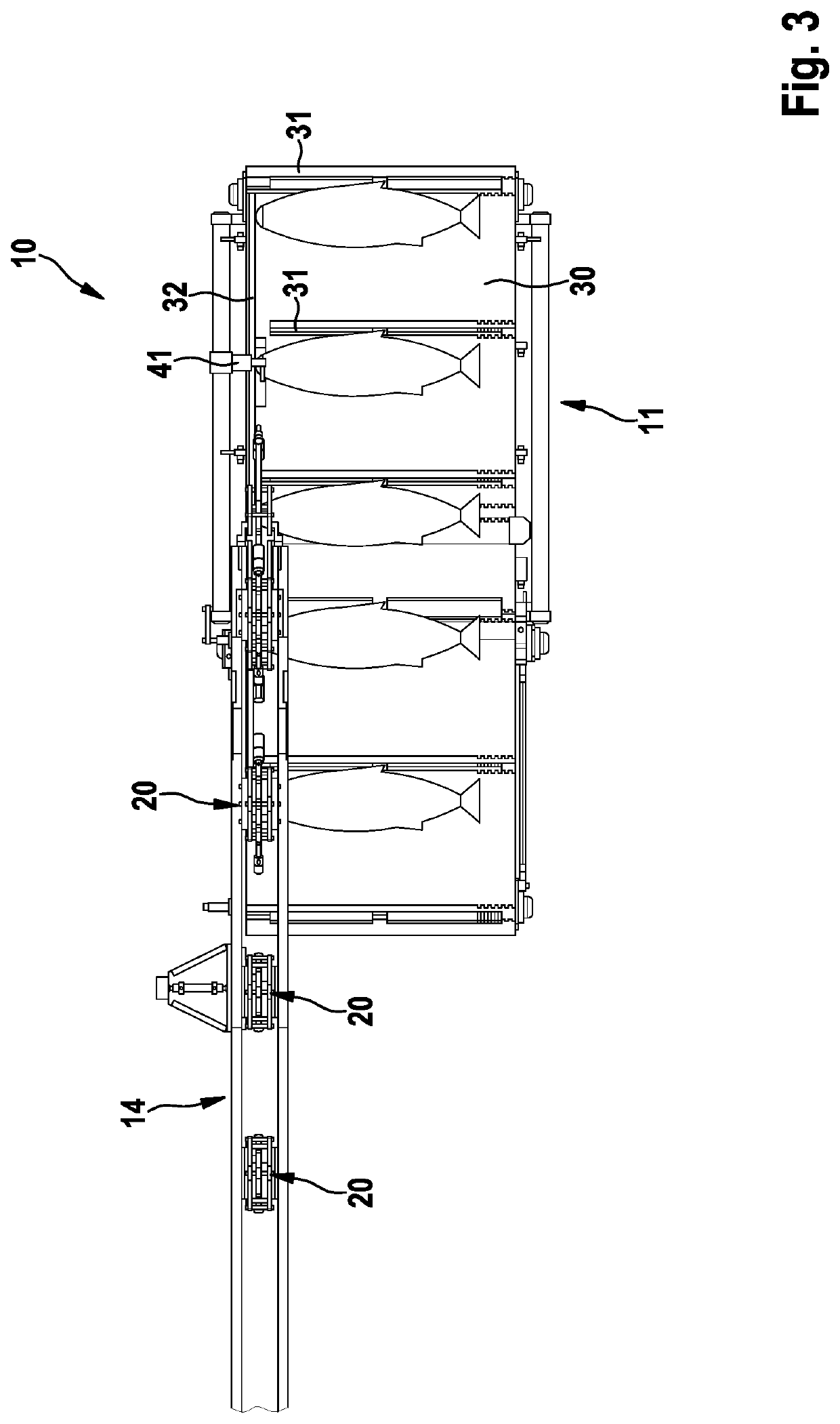

[0063]The transporting station illustrated in the drawing is used for changing the position of slaughtered salmon with opened abdominal cavities during transport abdomen-first in transport direction T from a horizontal to a suspended position. Of course, the transporting station according to the invention is also designed and configured for transferring the fish which are transported horizontally spine-first. The invention also relates in the same way to transporting stations with which other salmonidae and fish in general, whether slaughtered or unslaughtered, can be brought from a horizontal position into a suspended position.

[0064]The transporting station 10 illustrated in FIG. 1 is designed and configured for transporting fish transverse to their longitudinal extent in a transport direction T, and comprises a conveying device 11 for transporting individual, separated fish in a lying position along a transport path TL from an entry region E of the conveying device 11 to an exit r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com