Image detector having photoconductive layer, linear electrodes transparent to reading light, and signal-readout electrodes shaded from reading light

a photoconductive layer and image detector technology, applied in the field of image detectors, can solve the problems of increasing manufacturing costs, insufficient reading light entering the reading-side photoconductive layer, and increasing manufacturing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

first embodiment

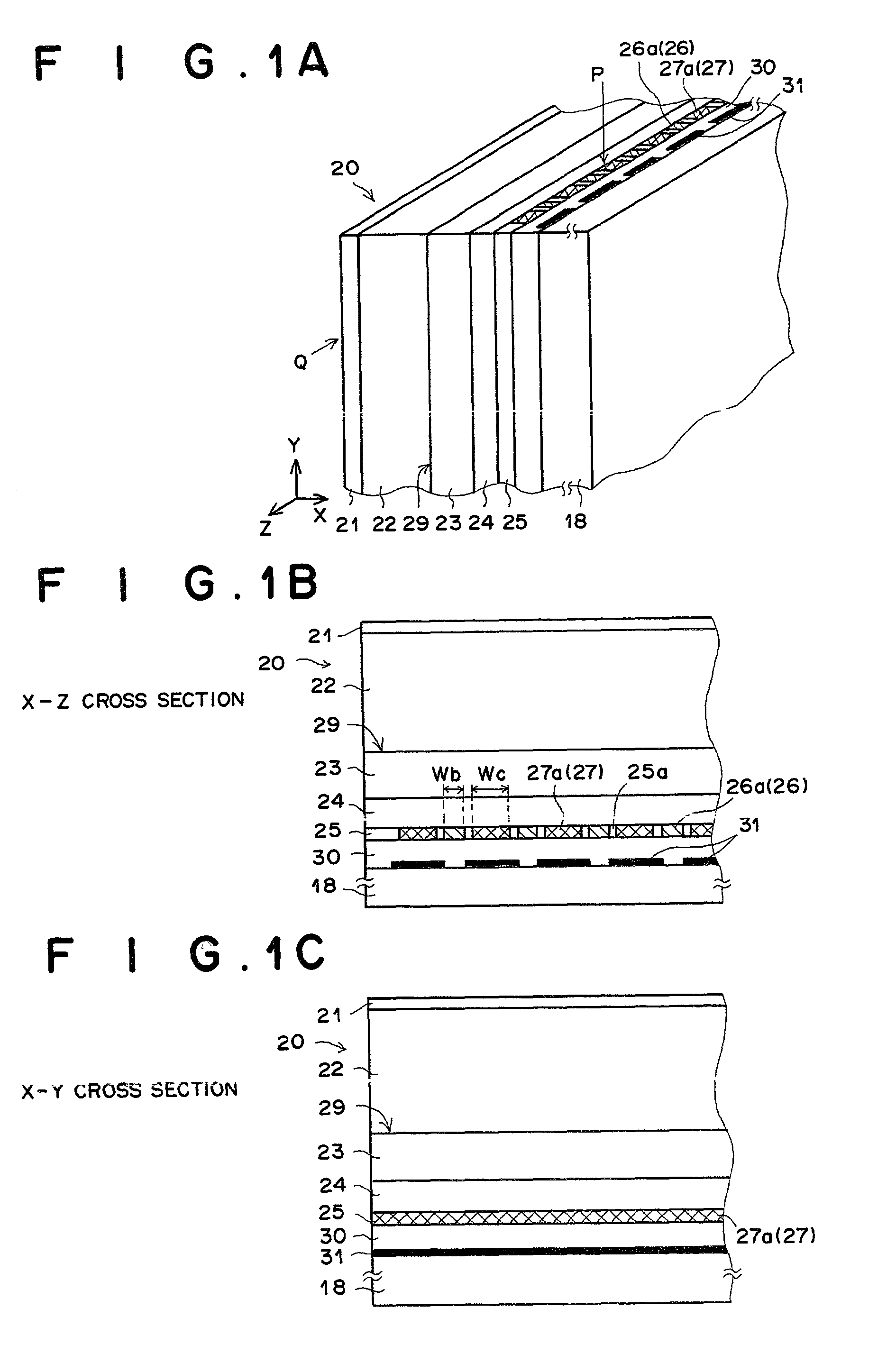

[0046] FIG. 1A a perspective view of a portion of a solid-state radiographic image detector as the first embodiment of the present invention, FIG. 1B illustrates an X-Z cross section of the portion of the solid-state radiographic image detector of FIG. 1A at the position indicated by the arrow Q in FIG. 1A, and FIG. 1C illustrates an X-Y cross section at the position of the portion of the solid-state radiographic image detector of FIG. 1A indicated by the arrow P indicated in FIG. 1A.

[0047] The solid-state radiographic image detector 20 illustrated in FIGS. 1A to 1C comprises a recording-side electrode layer 21, a recording-side photoconductive layer 22, a charge transport layer 23, a reading-side photoconductive layer 24, a reading-side electrode layer 25, an insulation layer 30, and a support 18, formed in this order.

[0048] The recording-side electrode layer 21 is transparent to recording light which carries image information. For example, the recording light is realized by X rays...

second embodiment

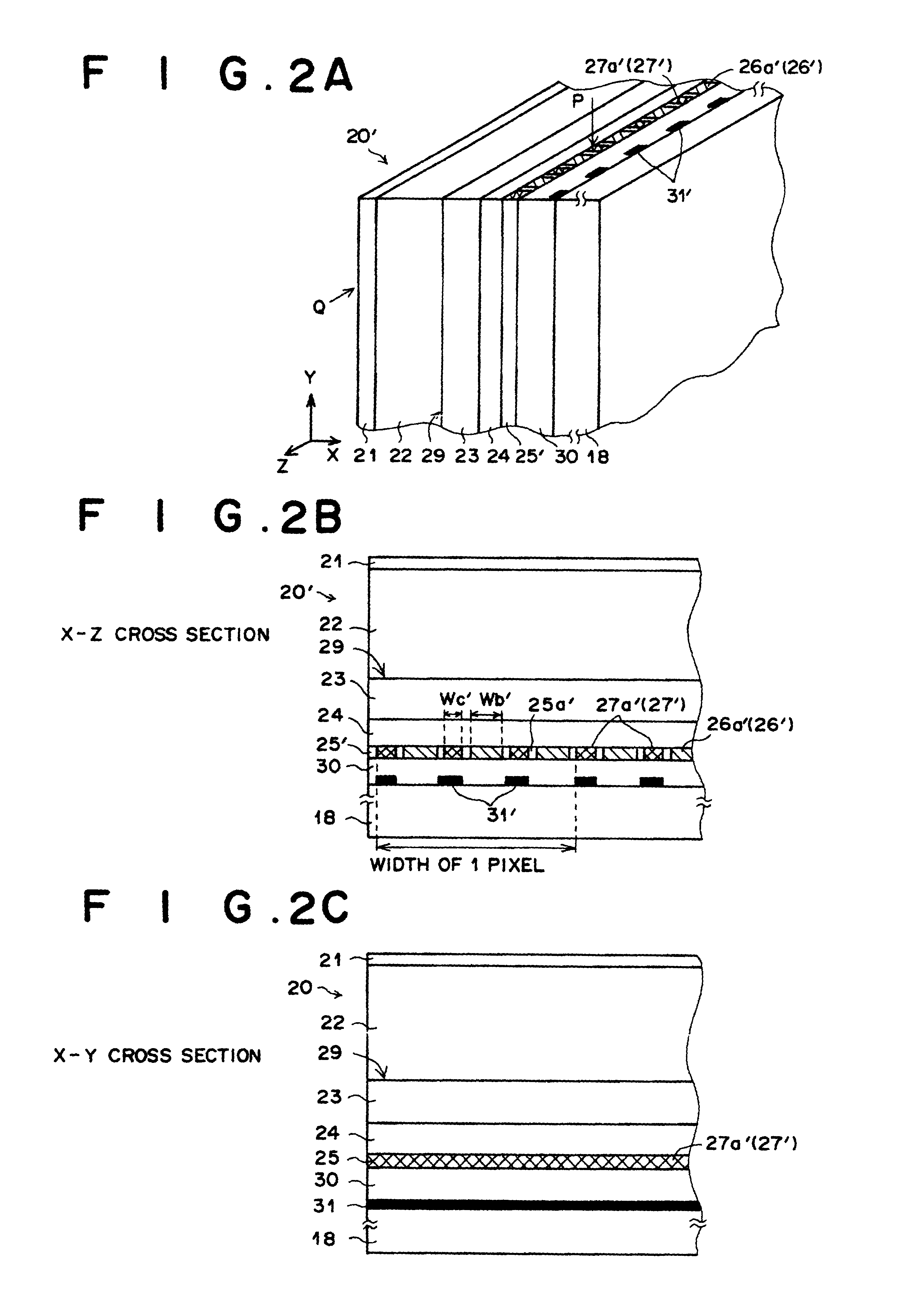

[0080] FIG. 2A is a perspective view of a portion of a solid-state radiographic image detector as the second embodiment of the present invention, FIG. 2B illustrates an X-Z cross section of the portion of the solid-state radiographic image detector of FIG. 2A at the position indicated by the arrow Q in FIG. 2A, and FIG. 2C illustrates an X-Y cross section at the position of the portion of the solid-state radiographic image detector of FIG. 2A indicated by the arrow P indicated in FIG. 2A. The solid-state radiographic image detector 20' illustrated in FIGS. 2A to 2C is identical to the solid-state radiographic image detector 20 illustrated in FIGS. 1A to 1C except for the features explained below. In FIGS. 2A to 2C, elements having the same reference numbers as FIGS. 1A to 1C have the same functions as the corresponding elements in FIGS. 1A to 1C.

[0081] In the solid-state radiographic image detector 20' illustrated in FIGS. 2A to 2C, a plurality of linear electrodes 26a' and a plural...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com