Multi-mode control system for variable camshaft timing devices

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

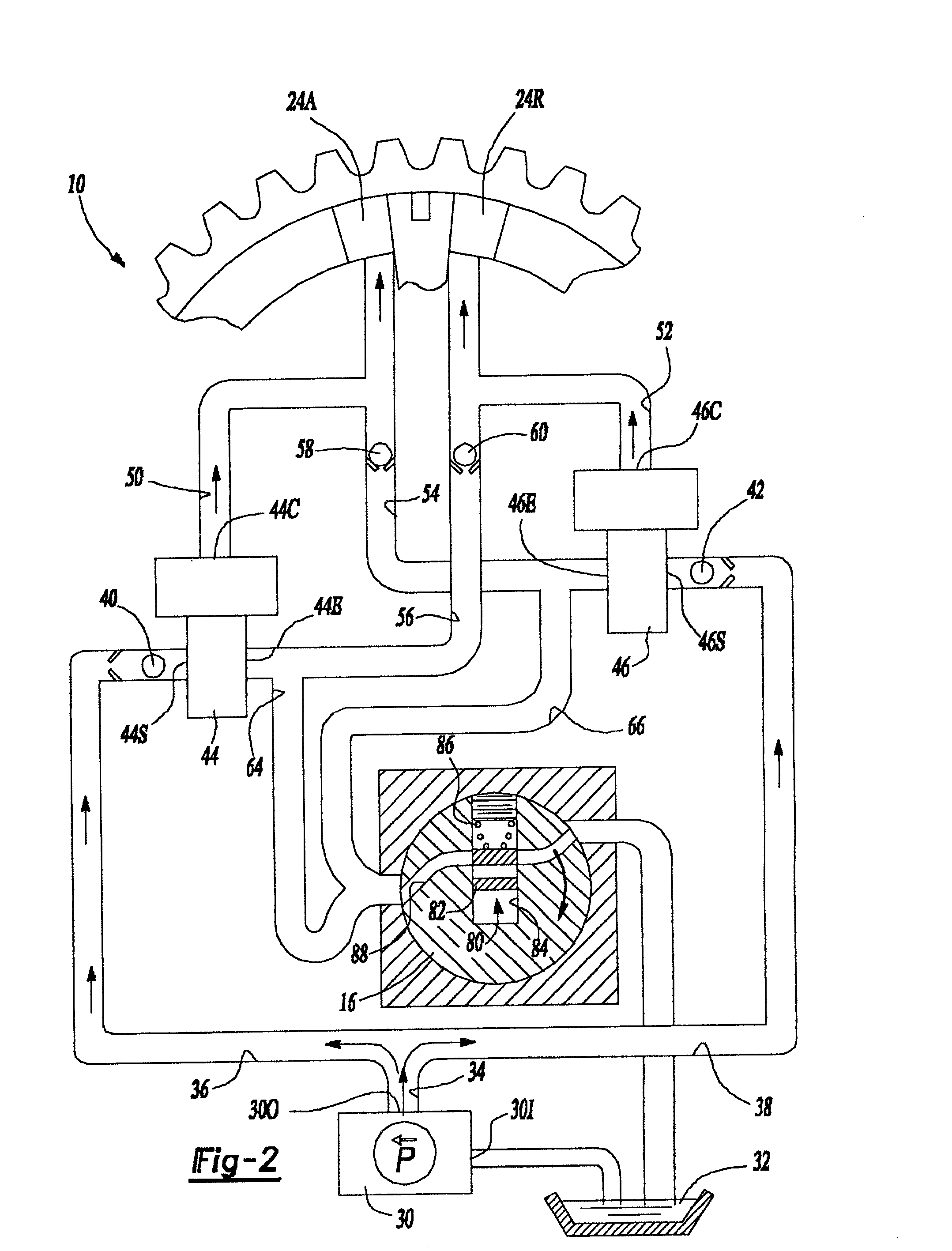

[0037] In general, an hydraulic timing system is provided for varying the phase of one rotary member relative to another rotary member. More particularly, the present invention provides a multi-mode Variable Camshaft Timing system (VCT) that is powered by, or is responsive to, engine oil under pressure from a pump and / or from engine oil under pressure pulsations inherent as a result of the tongue pulsations that occur in a rotating camshaft. While the present invention will be described in detail with respect to internal combustion engines, the VCT system is also well suited to other environments using hydraulic timing devices. Similarly, the fluid medium described herein is preferably engine oil, but any other standard hydraulic fluid may be used. Accordingly, the present invention is not limited to only internal combustion engines.

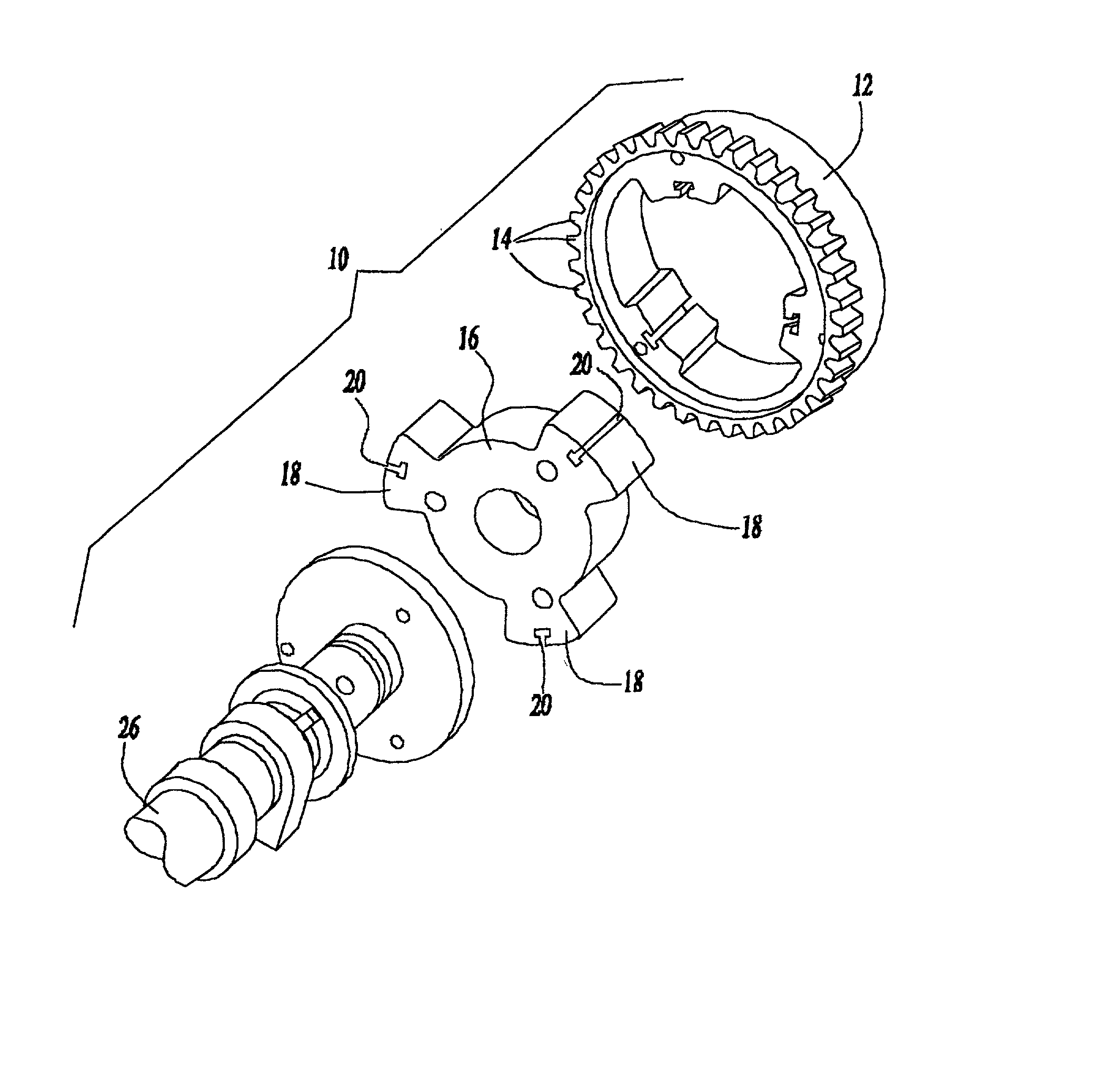

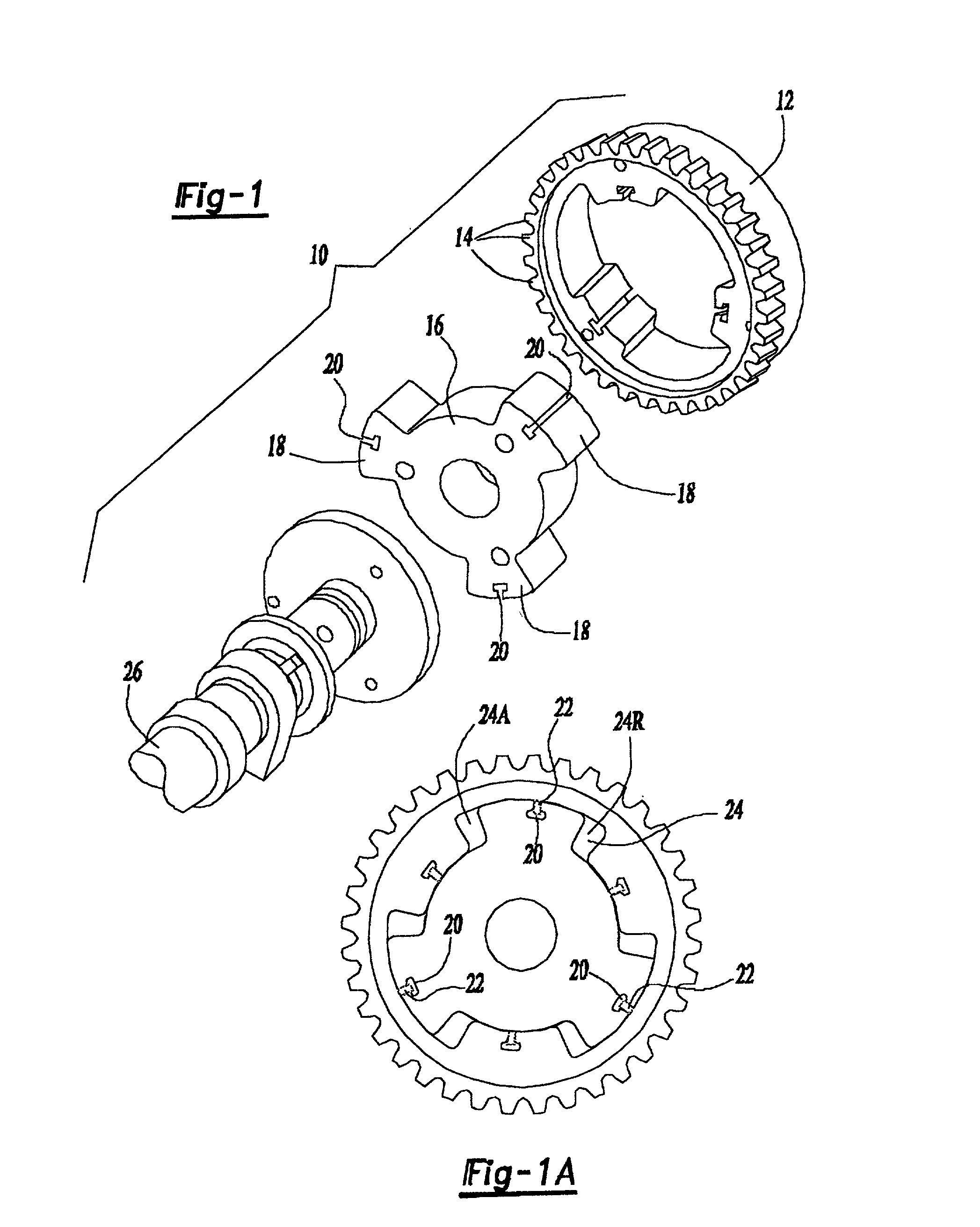

[0038] Referring now in detail to the Figures, there is shown in FIG. 1 a VCT apparatus 10 according to the preferred embodiment of the present inventio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com