Shelf stable carbonated milk beverage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

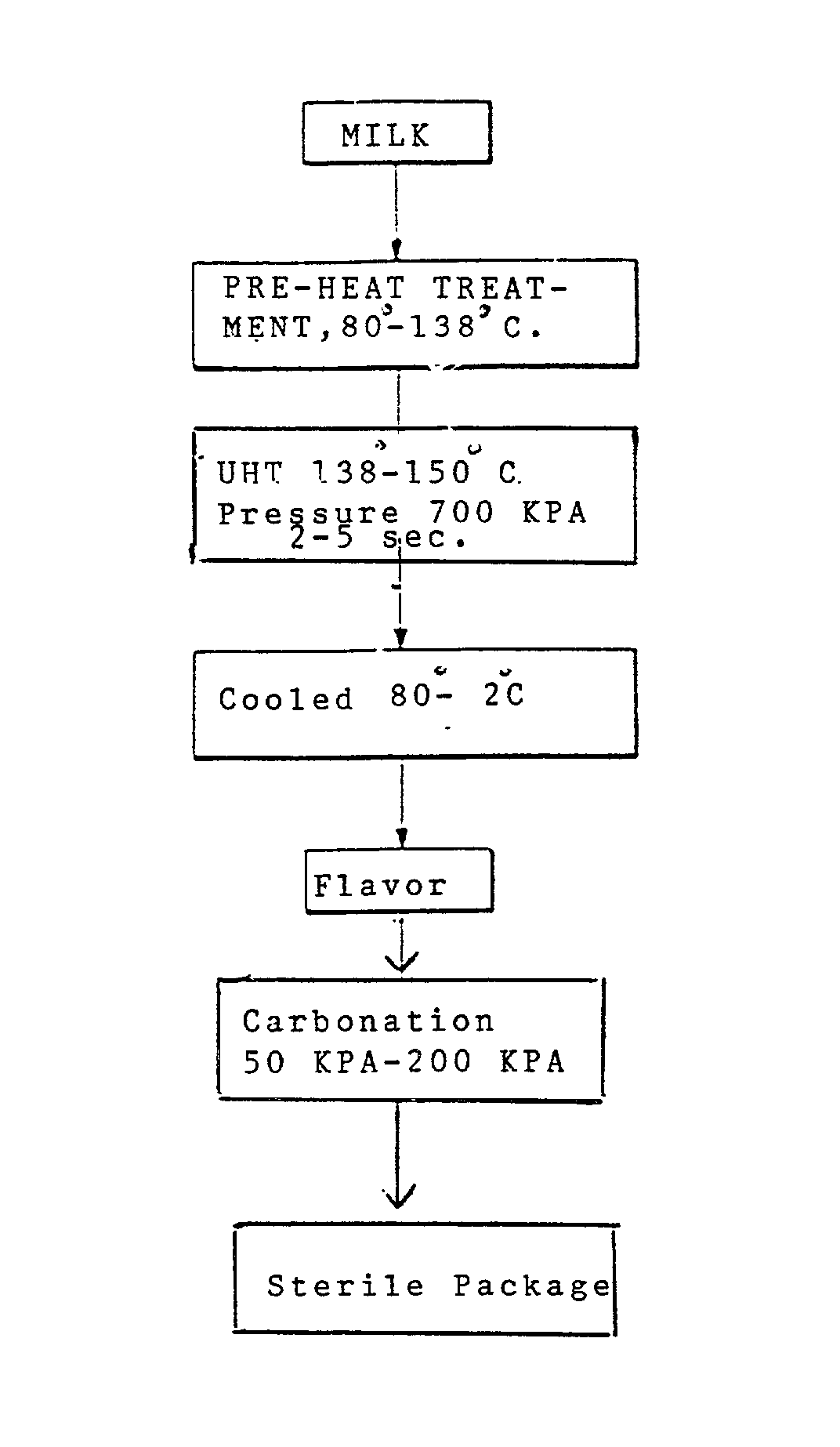

[0018] A. (Ultra Heat Treatment)

[0019] The milk sample, optionally containing any suitable, conventional or desirable additives is pumped from a stainless steel mix tank to an ultra heat treatment (UHT) plant where in the first stage which is the UHT pre-heater being a plate heat exchange, the milk is indirectly heated from a temperature of from 4 to 8 degrees centigrade to a temperature of about 138 degrees centigrade. After attaining a temperature of 138 degrees centigrade the milk is ultra heated from 138 to 150 degrees centigrade in the UHT heater where it is held at a pressure of 700 KPA or an appropriate pressure for about 2.25 seconds within limits as required to kill microorganisms, pathogens, bacteria and the like.

[0020] It is noted the precise conditions can change such as at a temperature of 153 degrees centigrade or similar. Thereupon it is cooled, preferably to below 10 degrees centigrade, more preferably to 2 degrees centigrade immediately. At this point a flavoring ag...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com