Soft touch lifter

a lifter and soft touch technology, applied in the direction of lifting devices, mechanical conveyors, conveyors, etc., can solve the problems of increasing the overall cycle time of the automotive production line, increasing the overall cycle time of the framing system, etc., and achieve the effect of reducing the speed of impact of the tooling against the automotive body components

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

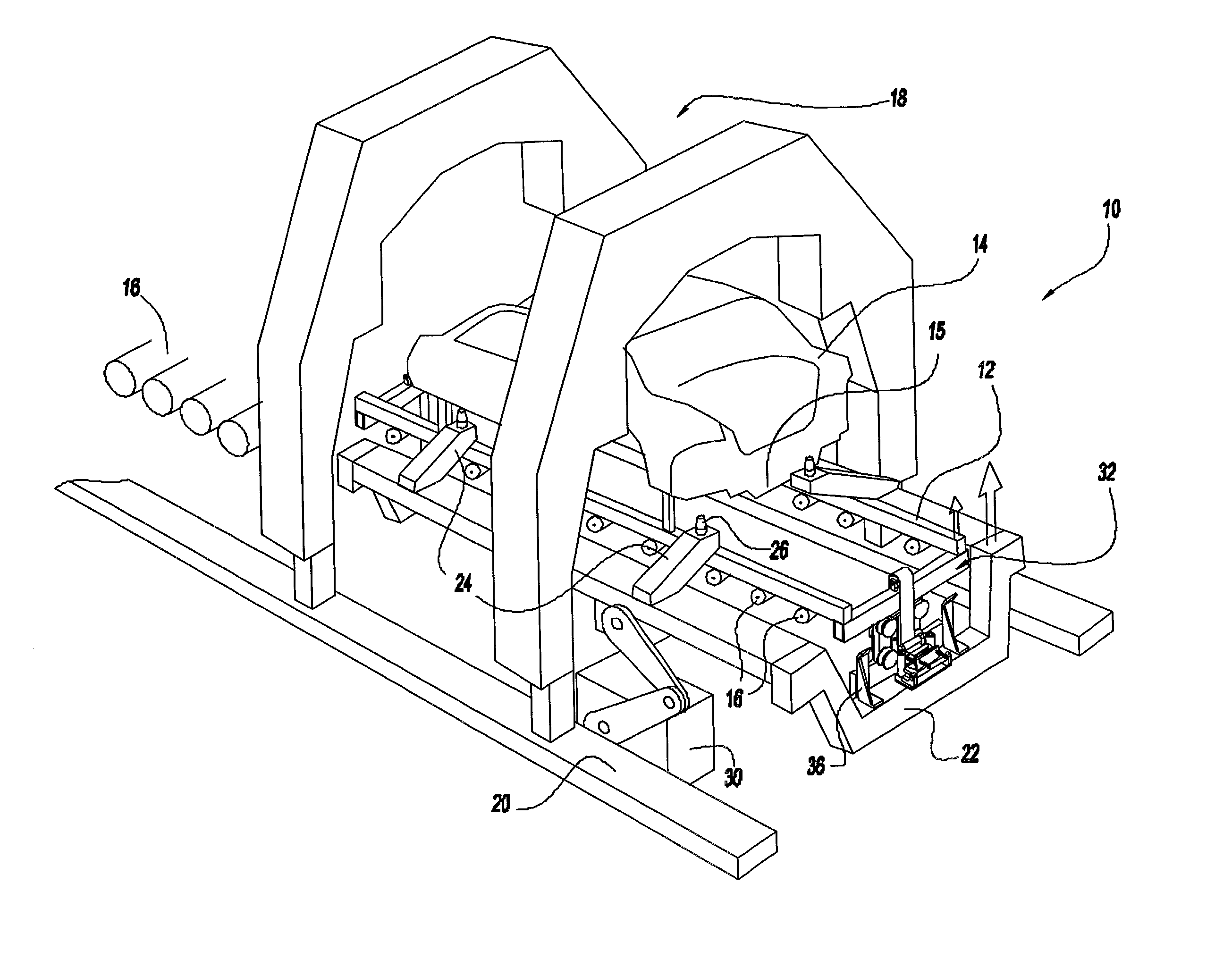

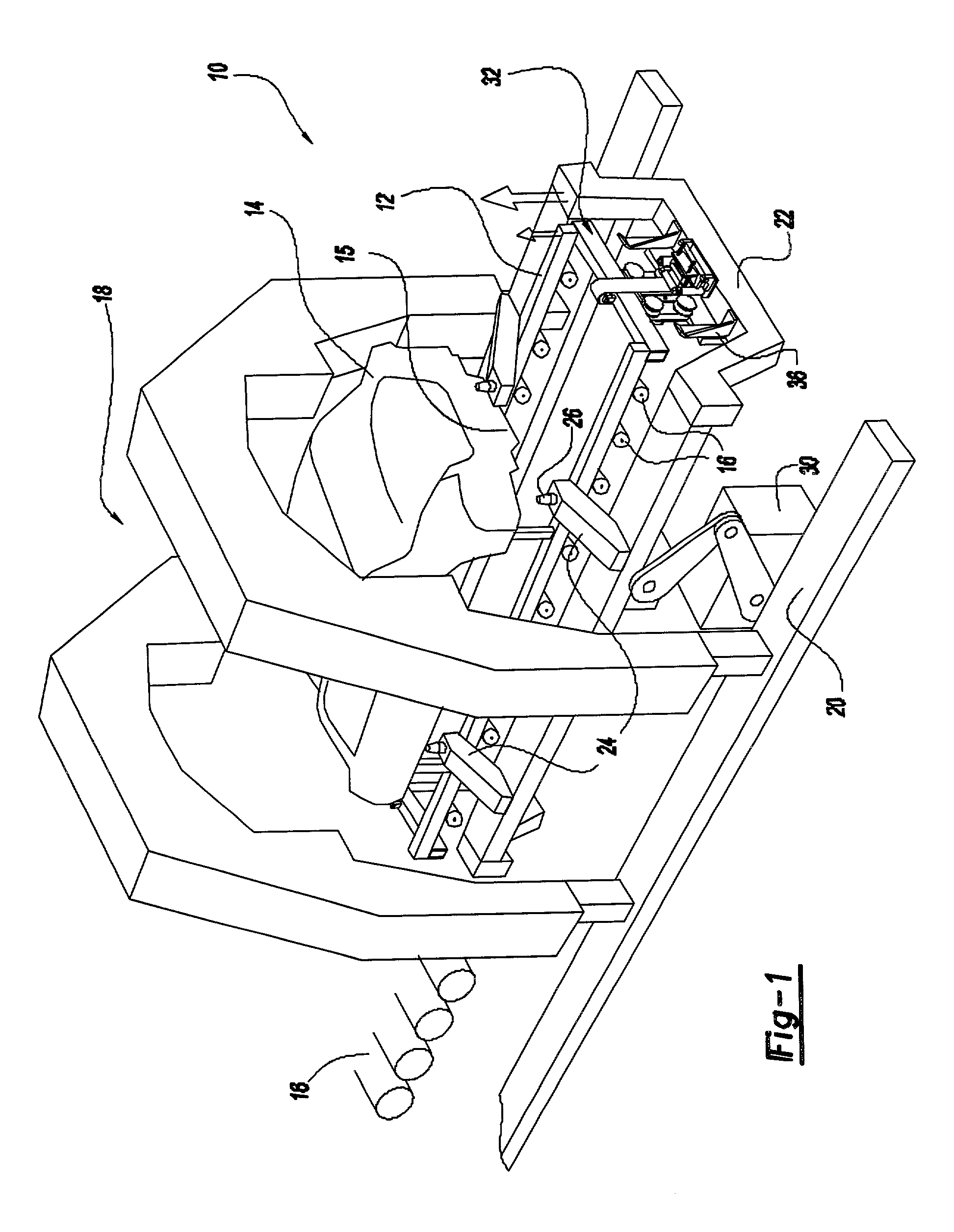

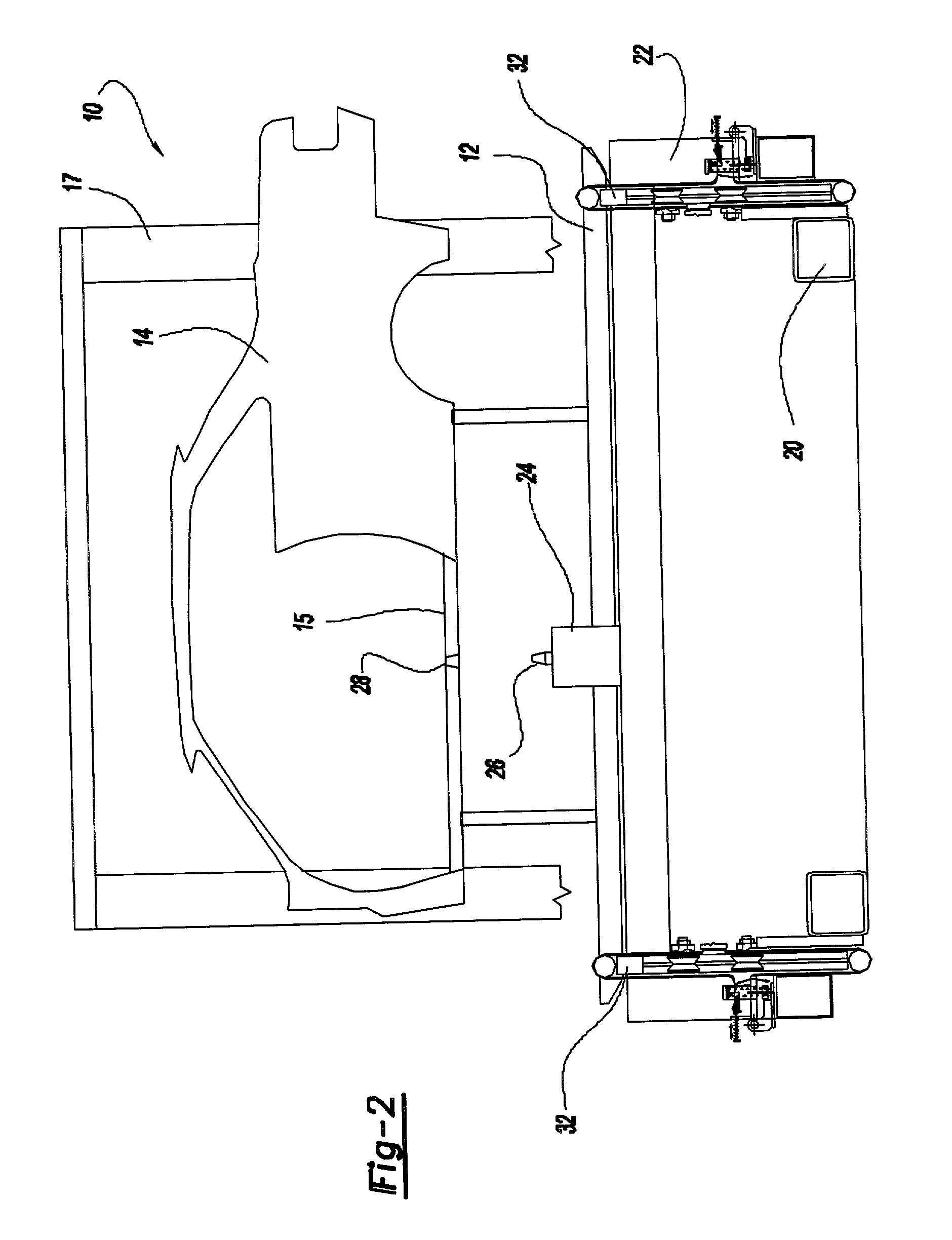

[0024] With reference first to FIG. 1, an elevational view of an automotive framing system 10 including a soft touch lifter of the present invention is illustrated. In the conventional fashion, a skid 12 supports two or more automotive body components 14, 15 which are either not attached together or only loosely attached together. These automotive body components 14, 15 are supported on the upper surface of the skid 12. The skid 12, together with its supported body components 14, 15, is transported by any conventional means, such as a roller conveyor system 16 (illustrated diagrammatically) to a geometry station 18.

[0025] With reference now to FIGS. 1, 2 and 4-6, the geometry station 18 includes a base 20 which is fixed relative to a ground support surface. A lift frame 22 is vertically slidably mounted to the base 20 and movable between a lower position, illustrated in FIGS. 1, 2 and 4, and an upper position, illustrated in FIG. 6. In the conventional fashion, an automotive underbo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com