Medium caliber high explosive dual-purpose projectile with dual function fuze

a projectile and dual-functional technology, applied in the field of fuze, can solve the problems of unarmored, threats, chemical energy projectiles that are less effective against soft targets, and unwanted variations in performan

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

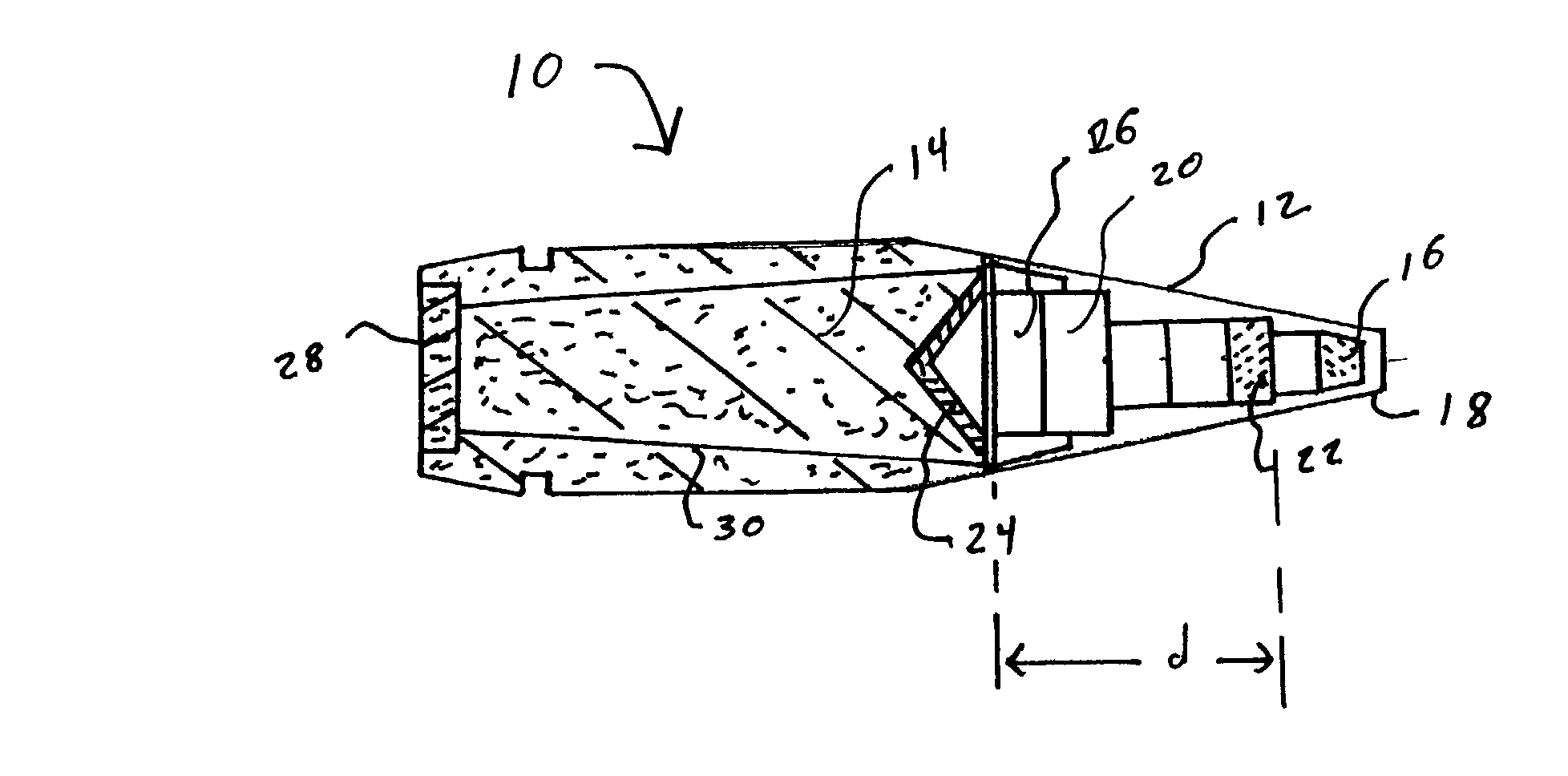

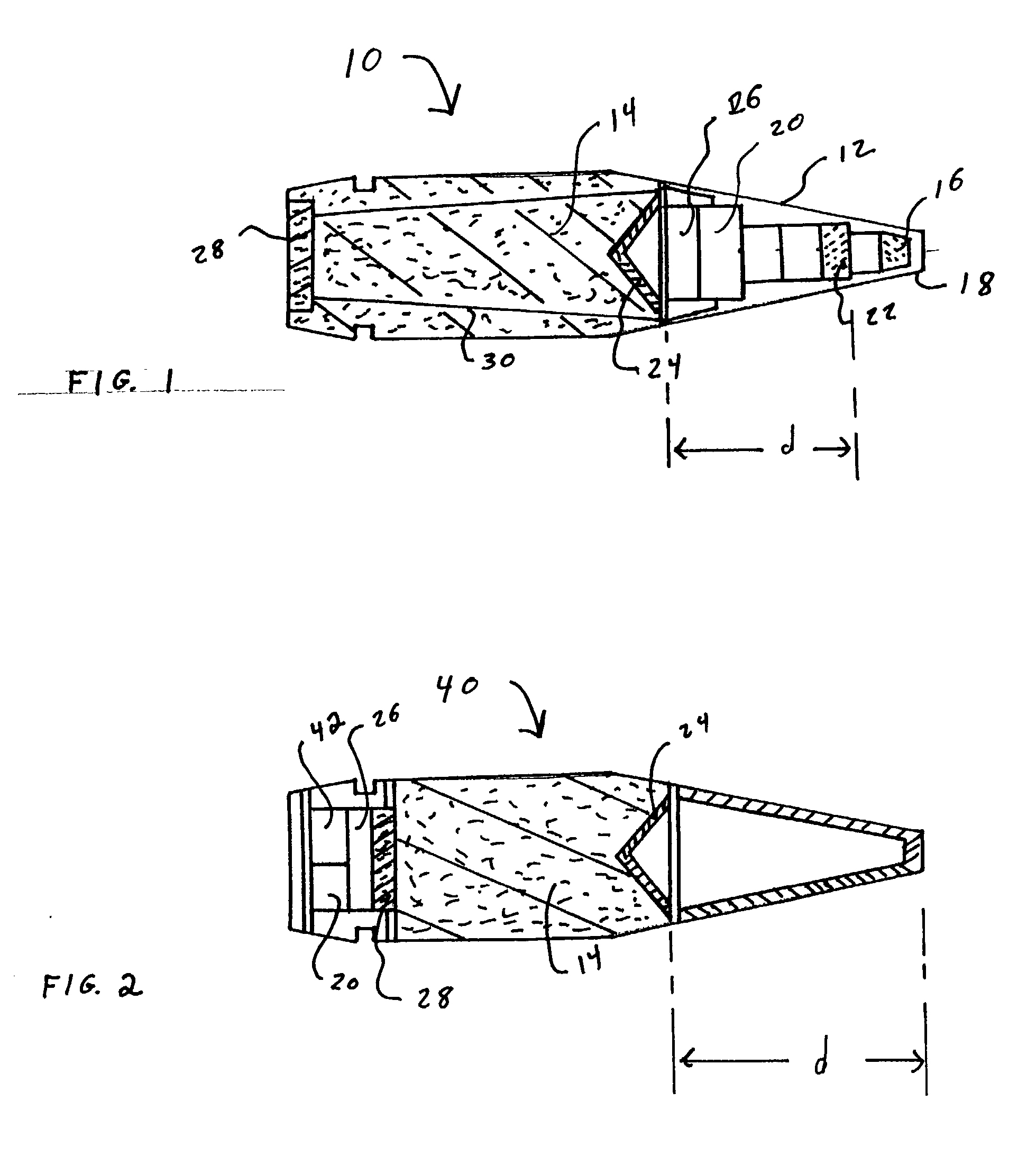

Image

Examples

Embodiment Construction

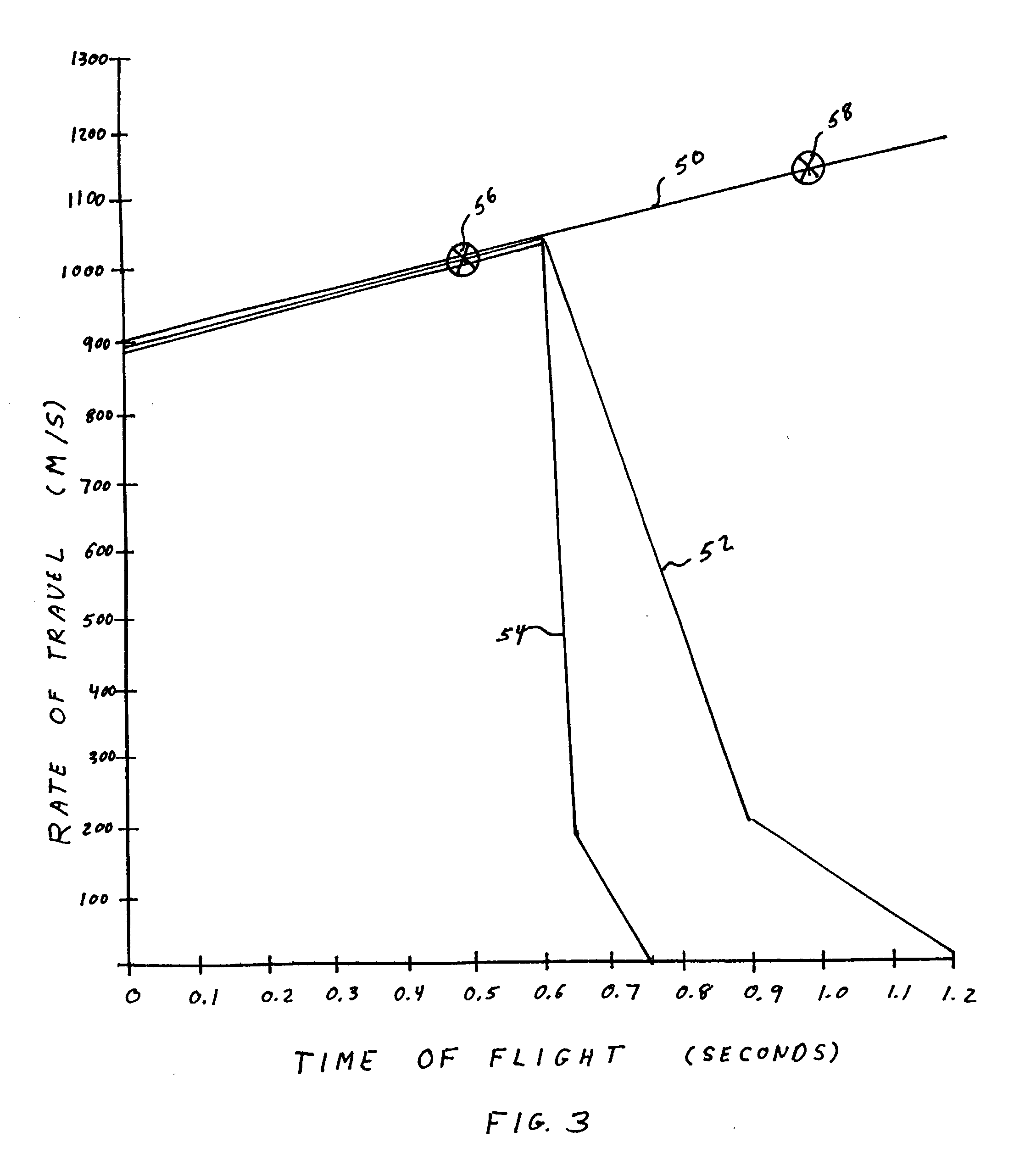

[0055] A piezoelectric crystal from Kinetic Ceramics, Inc. of Hayward, Calif. having a rated sensitivity of 0.37 mV / g was incorporated into a simulated projectile. Weights were dropped on the nose of the projectile from varying heights to simulation impact accelerations of varying g-forces. An impact acceleration force of from 1,000 g to 10,000 g was deemed to simulate impact with a soft target and an impact acceleration in excess of 20,000 g was deemed to simulate impact with a hard target. The voltage generated by the piezoelectric crystal following these simulated impact was recorded. As shown from FIG. 5, the target type was readily determined from the voltage output. An output of about 3 volts or less corresponded to a soft target and an output of about 4.4 volts or more corresponded to a hard target. There was a standard deviation in the measured voltages of about .+-.17%.

[0056] It is apparent that there has been provided in accordance with the invention a fuze that fully sati...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com