Drying method and drying apparatus for coating layer

a drying apparatus and coating layer technology, which is applied in the direction of lighting and heating apparatus, drying machines with progressive movements, furnaces, etc., can solve the problems of uneven thickness of coating layer, unevenness or mura generation, and poor conditions of coating layer

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] In the present invention, it is preferable that a blow-drying apparatus is provided after a drying apparatus. In this case, when much solvent (especially organic solvent) remains in the solution cast on a web, the drying unevenness easily generated. Therefore, in the present invention, the coating solution contains preferably at least 50% by mass.

[0031] Further, the effect of the present invention is very effective, when the organic solvent is contained in the coating solution, otherwise when only one or more organic solvent is used as a solvent of the coating solution. Furthermore, the effect of the present invention is more effective, when the boiling point of the organic solvent is low.

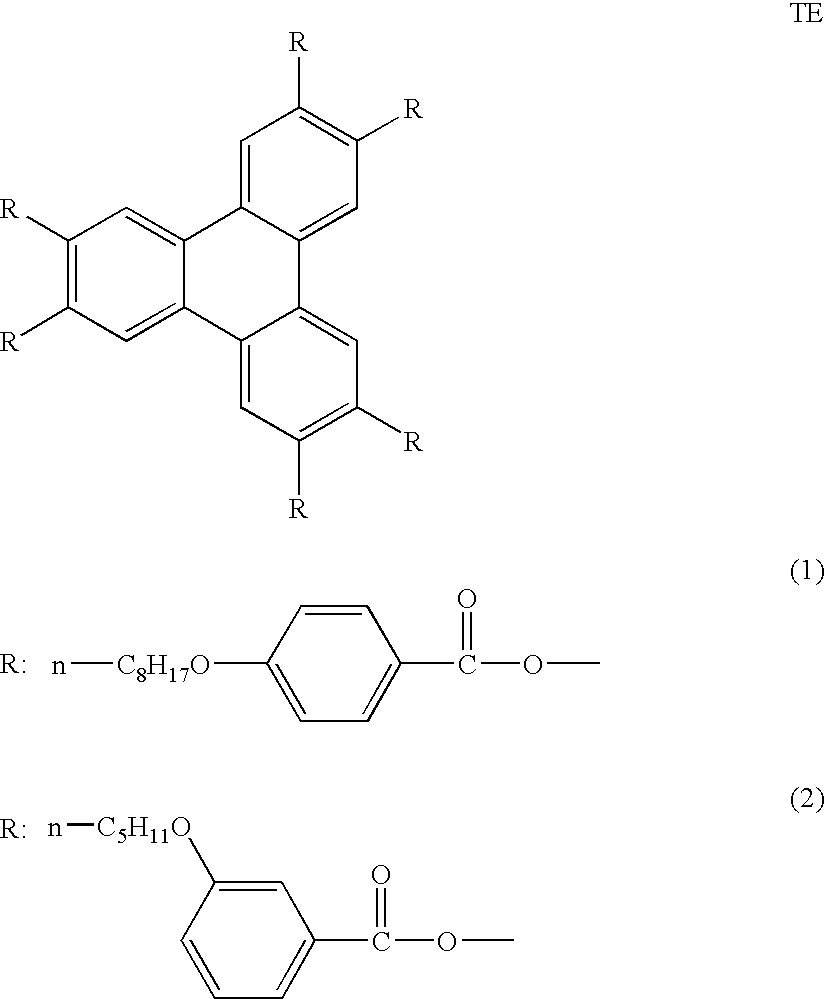

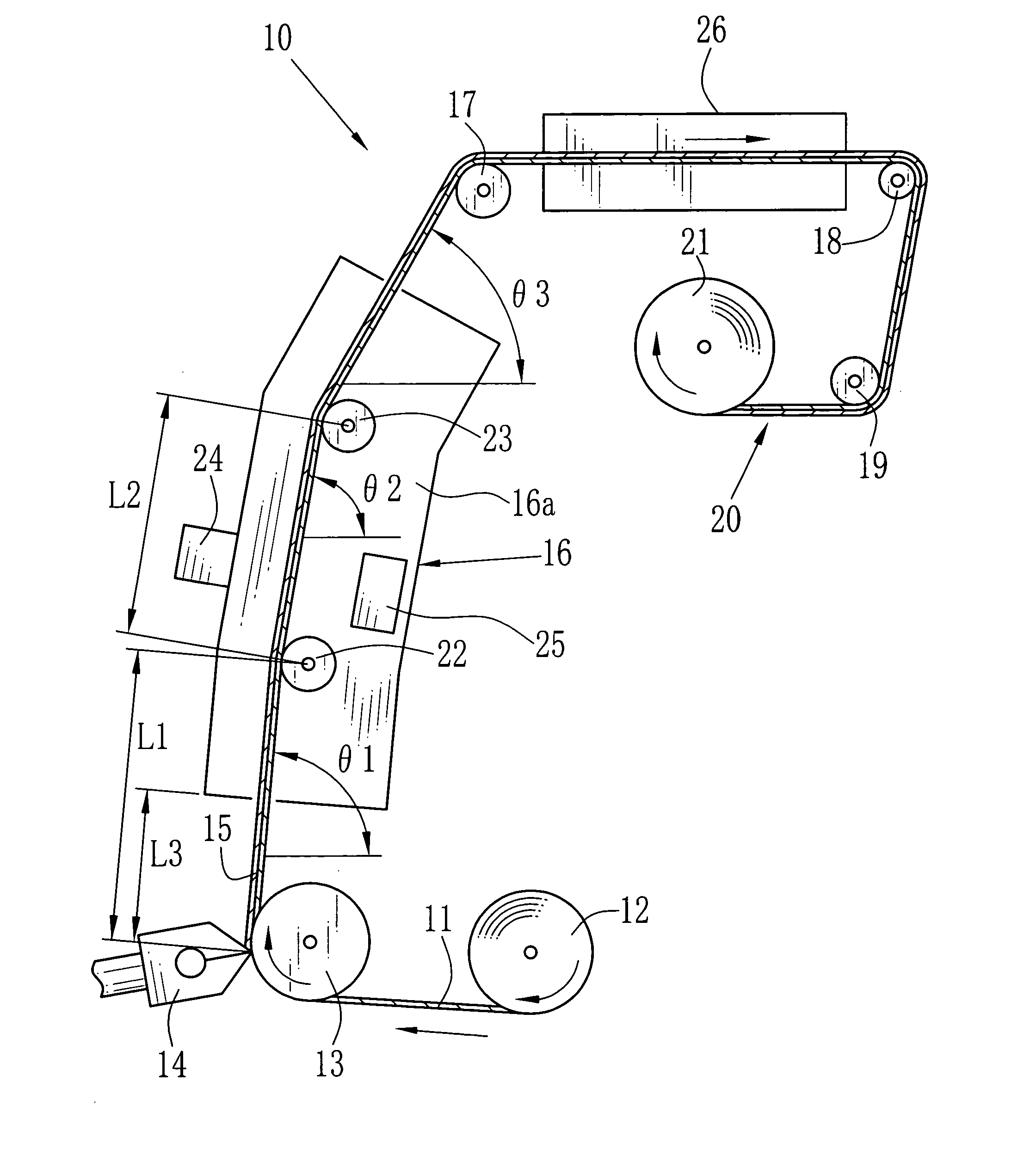

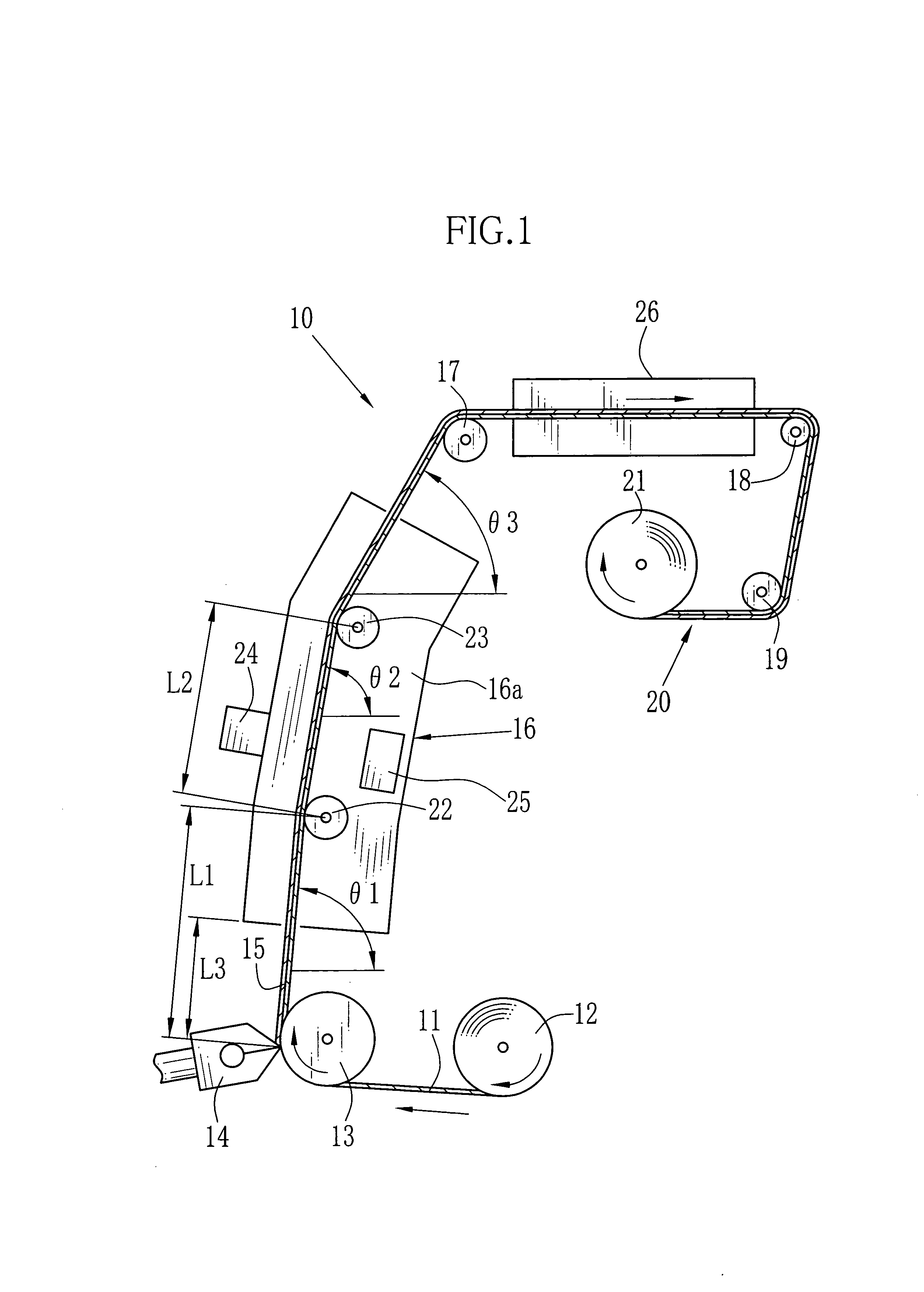

[0032] In FIG. 1, a coating / drying line 10 has a feeding apparatus 12, a back-up roller 13, an extrusion die 14, a drying apparatus 16, rollers 17-19, and a winding apparatus 21. The feeding apparatus 12 unwinds and feeds a web 11 wound in a web roll. The back-up roller 13 confront to the ex...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com