Imaged articles comprising a substrate having a primed surface

a technology of imaged articles and substrates, applied in the direction of instruments, signs, transportation and packaging, etc., can solve the problems of insufficient wetting of imaged articles with non-contact printing methods, typical image defects, and generally inability to dilute screen printing ink

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

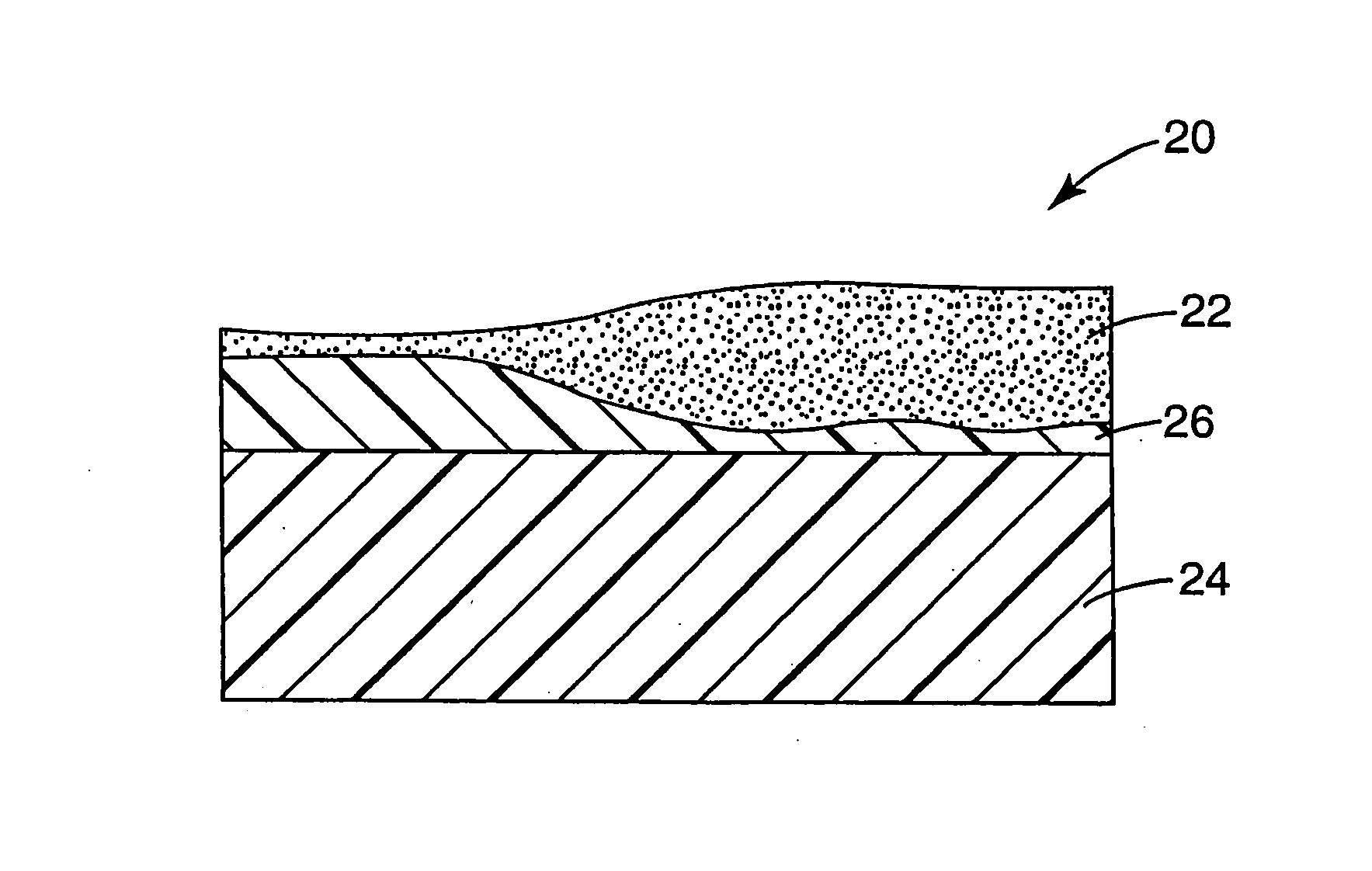

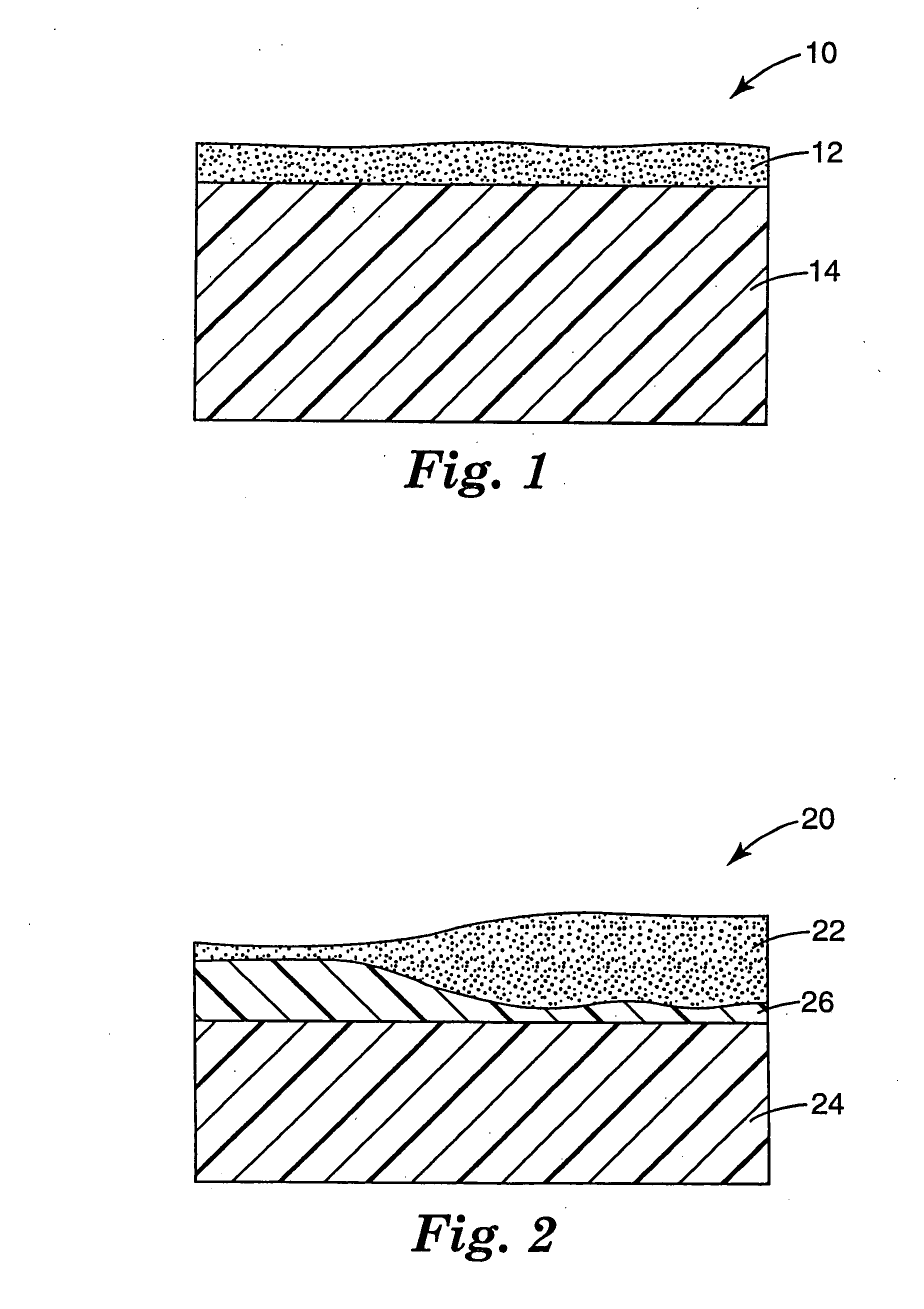

Image

Examples

example 13

[0181] Example 13 was prepared in the same manner as Example 4 except Primer K was used. The results were as follows.

180-10 Primed with Primer K

[0182]

12 Primer K Ink Uptake Dot Size Thickness Rating (microns) Comments 0.5 microns Good 207 Excellent resolution and good image 1.0 microns Good 193 Excellent resolution and good image 2.7 microns Good 180 Excellent resolution and good image

example 14

[0183] Example 14 was prepared in the same manner as Example 4 except for using Primer P. The results were as follows:

Substrate 180-10 Primed with Primer P

[0184]

13 Primer P Ink Uptake Dot Size Thickness Rating (microns) Comments 0.5 microns Good 171 Good resolution, some banding 1.0 microns Good 165 Good resolution, some banding 2.7 microns Good 166 Good resolution, some banding

example 15

[0185] Example 15 was prepared in the same manner as Example 4 except for using Primer Q. The results were as follows.

[0186] 180-10 Primed with Primer Q

14 Primer Q Ink Uptake Dot Size Thickness Rating (microns) Comments 0.5 microns Good 172 Good resolution and good image 1.0 microns Good 168 Good resolution and good image 2.7 microns Good 181 Good resolution and good image

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

| temperature | aaaaa | aaaaa |

| entrance angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com