Creping adhesive and products and process incorporating same

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

example

[0072] The following example was performed in order to compare base webs made according to the present invention with base webs that have been used in the past as a wiping product. In particular, base webs treated with a bonding material in accordance with the present invention were compared with base webs treated and creped with conventional bonding materials.

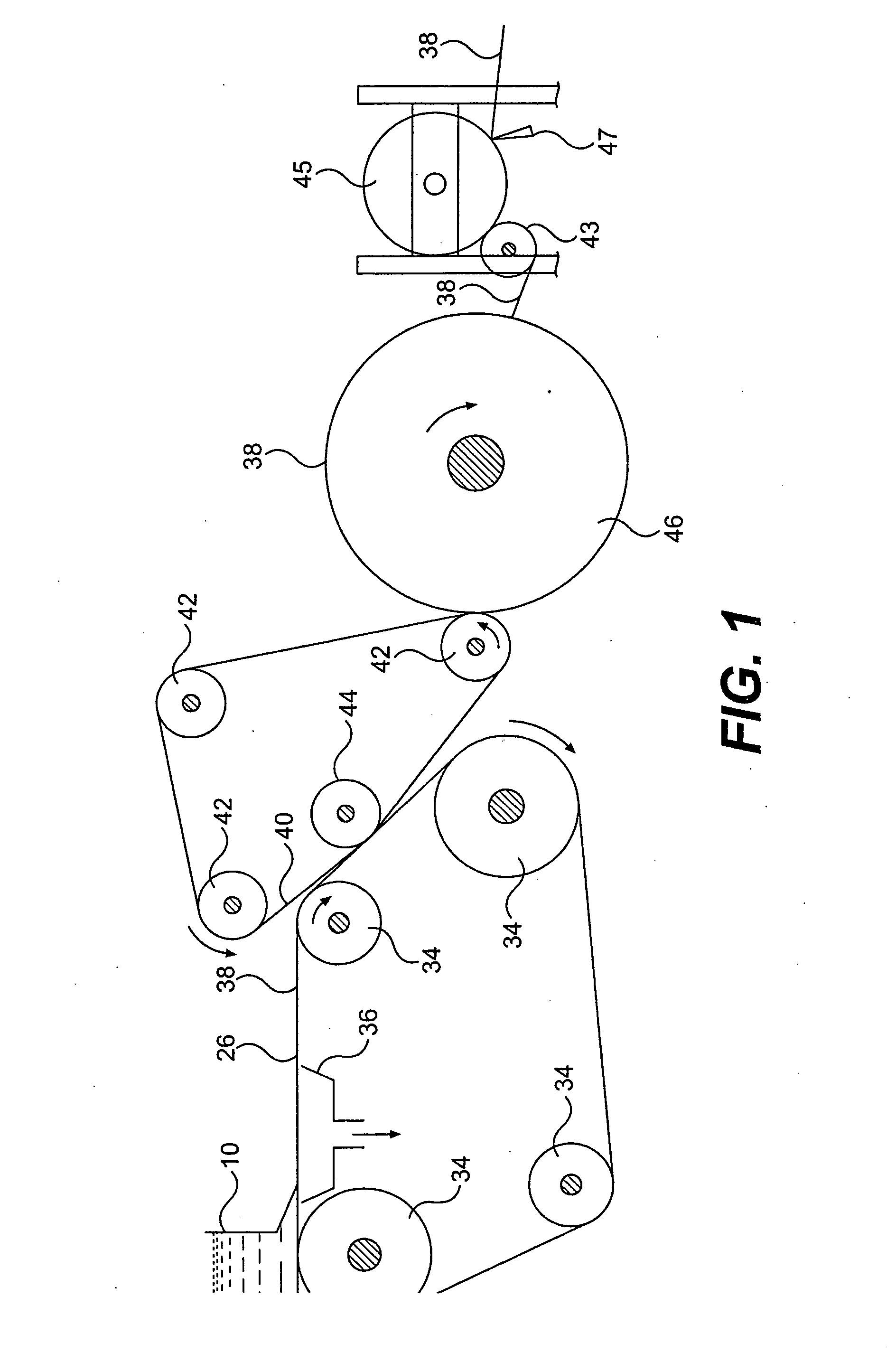

[0073] Specifically, in this sample, a fibrous web was formed according to a process similar to the one illustrated in FIG. 1. The fibrous web was made from pulp fibers, namely softwood fibers and had a basis weight of from about 39 pounds per ream to about 48 pounds per ream.

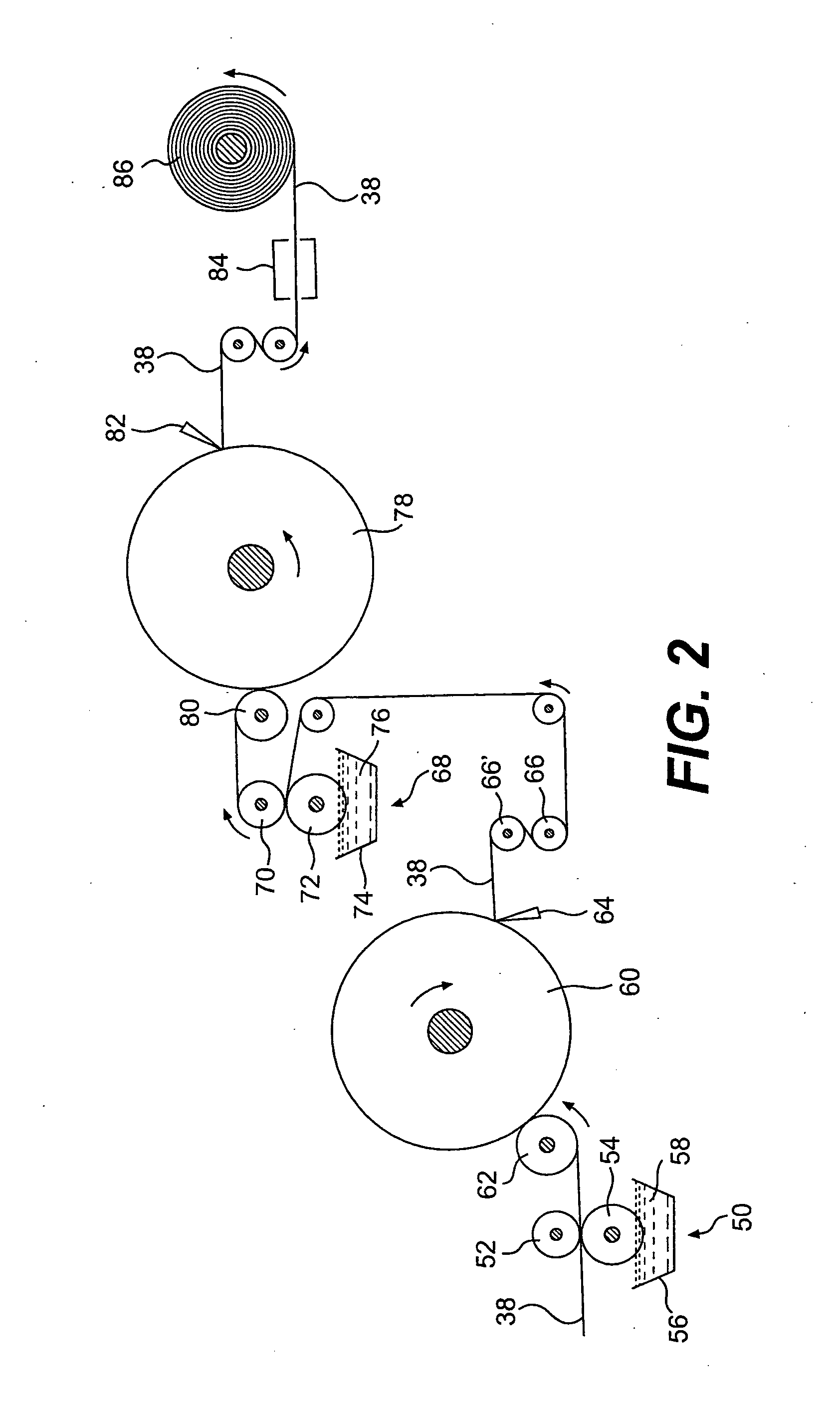

[0074] After the web was formed, a bonding material was printed on each side of the web and each side was creped similar to the process illustrated in FIG. 2. In one embodiment, representing the control, the bonding material used was a conventional creping adhesive containing a cross-linked ethylene vinyl acetate copolymer. In another embodiment, compos...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

| Fraction | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com