Temperature and condensation control system for functional tester

a temperature and condensation control and functional tester technology, applied in the direction of electronic circuit testing, measurement devices, instruments, etc., can solve the problems of affecting the accuracy of affecting the accuracy of test results, so as to reduce the exposure of test equipment and chips, prevent condensation on surfaces, and reduce the effect of condensation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

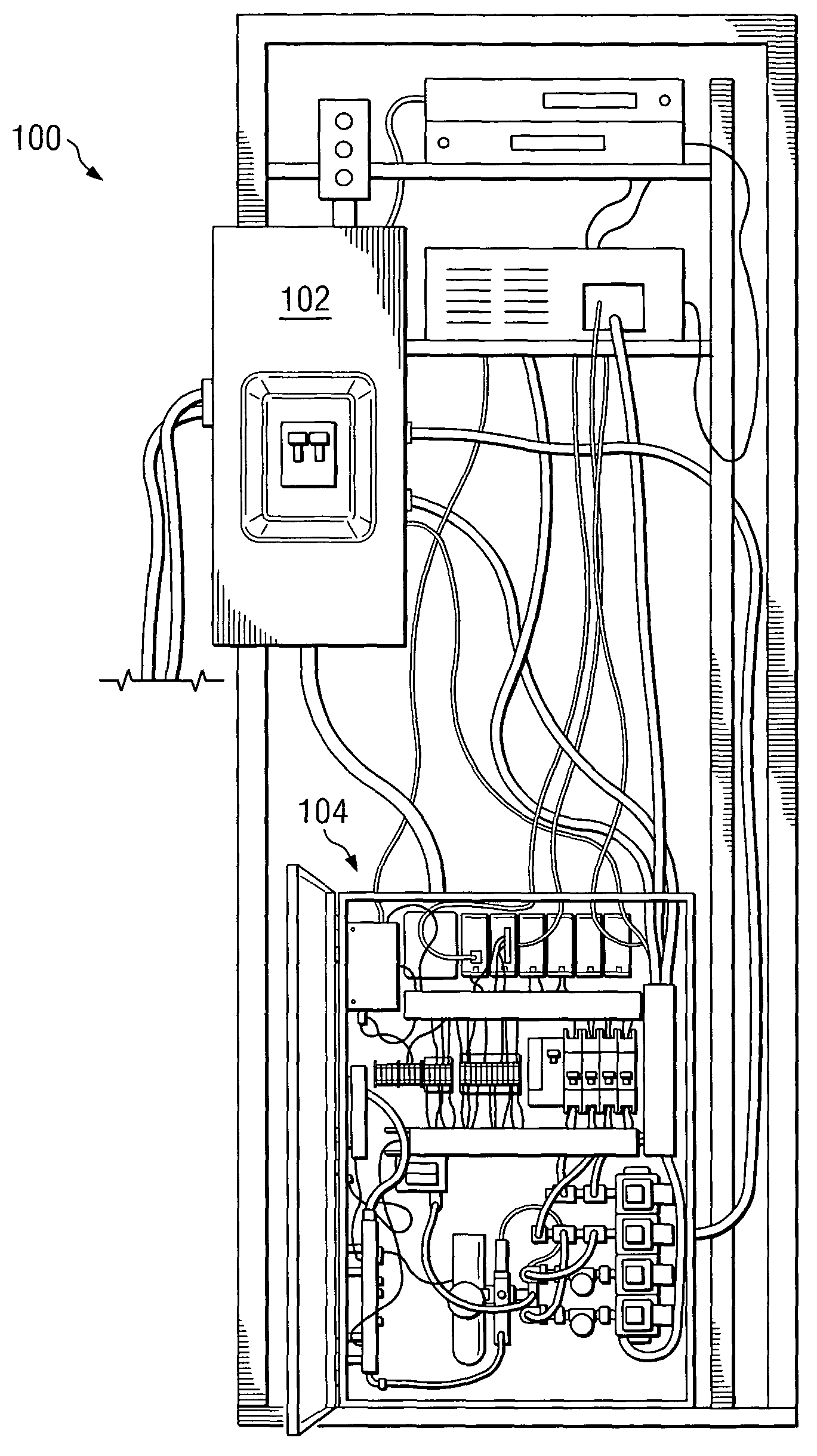

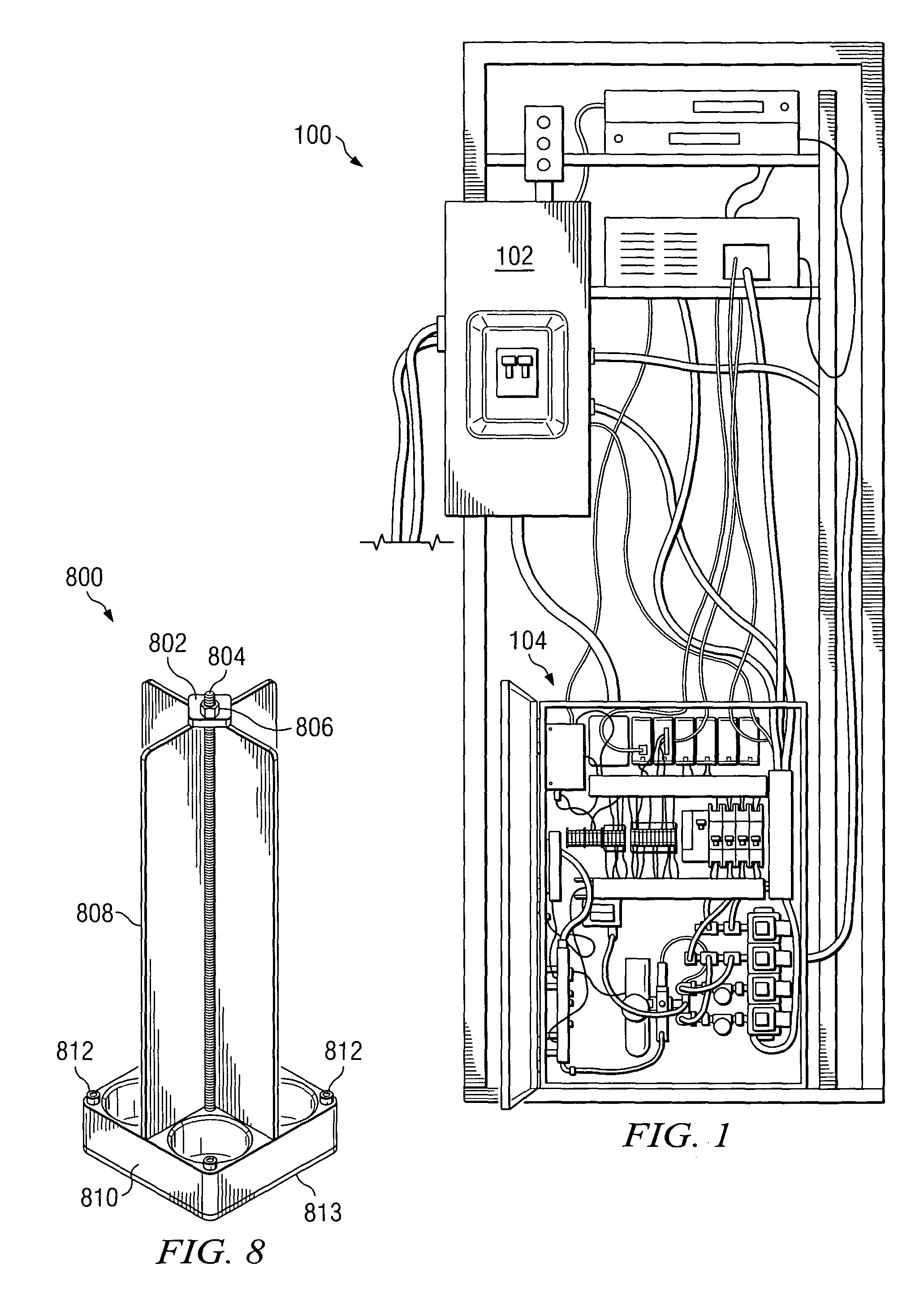

[0021] The present invention is described with reference to the several figures. FIG. 1 shows a rear view of a testing unit consistent with a preferred embodiment. Unit 100 includes equipment necessary for performing testing of chips, such as a nest (not shown, see FIG. 3), thermal control box 104, and power box 102. In addition, innovative testing unit 100 includes a chiller for supplying cooled fluid, and card for receiving the chip to be tested. In a preferred embodiment, the nest centers on the location where the tested chip sockets to the card.

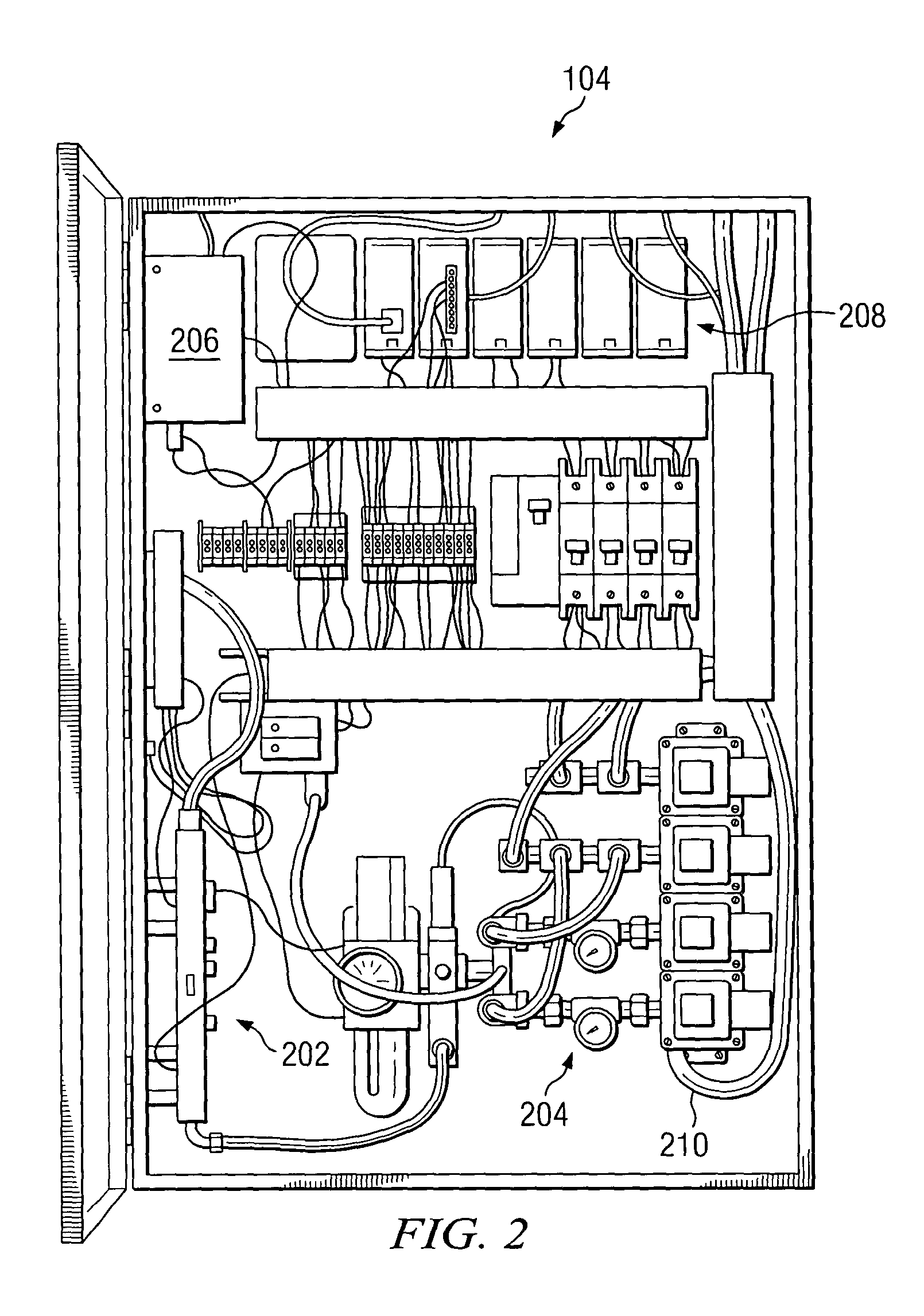

[0022]FIG. 2 shows a detail of the thermal control box. The box 104 is preferably filled with dry air to reduce condensation, as described below. In a preferred embodiment, it includes air / helium controls 202 which provide control for injection of dry air where condensation control is required. Compressed air is also used to drive the cold plate up and down, while helium is preferably used to improve the thermal interface between the chi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com