Structured reclosable packaging

a technology of reversible packaging and structure, which is applied in the field of reversible packaging with interior support, can solve the problems of not meeting the needs of the modern consumer, the design of the bag is not suitable for the modern consumer, and the bag packaging generally cannot maintain a predetermined shape or configuration, and cannot stand upright, etc., to achieve the effect of reducing the overall production cost, minimizing the required materials, and cost-effectiv

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

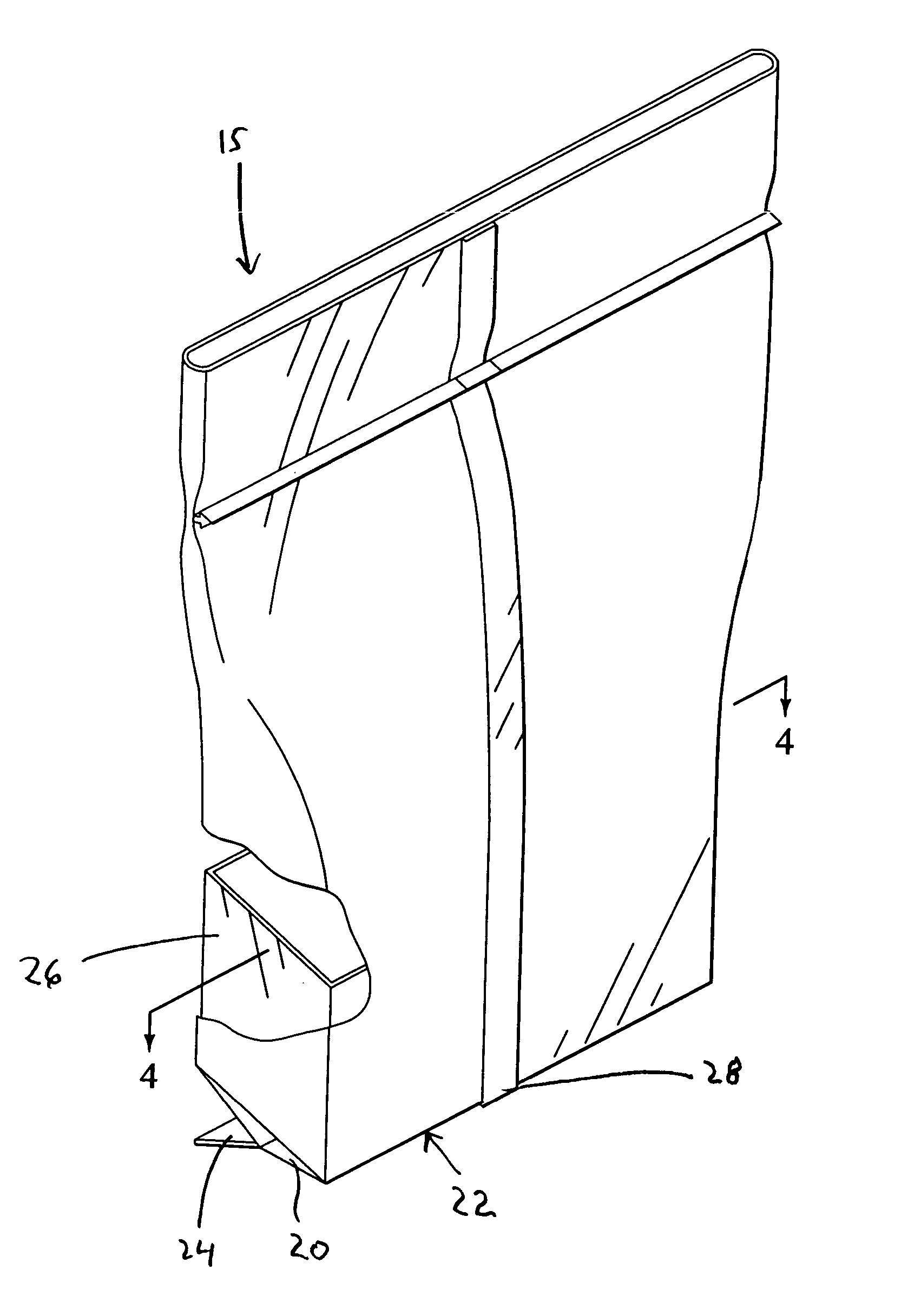

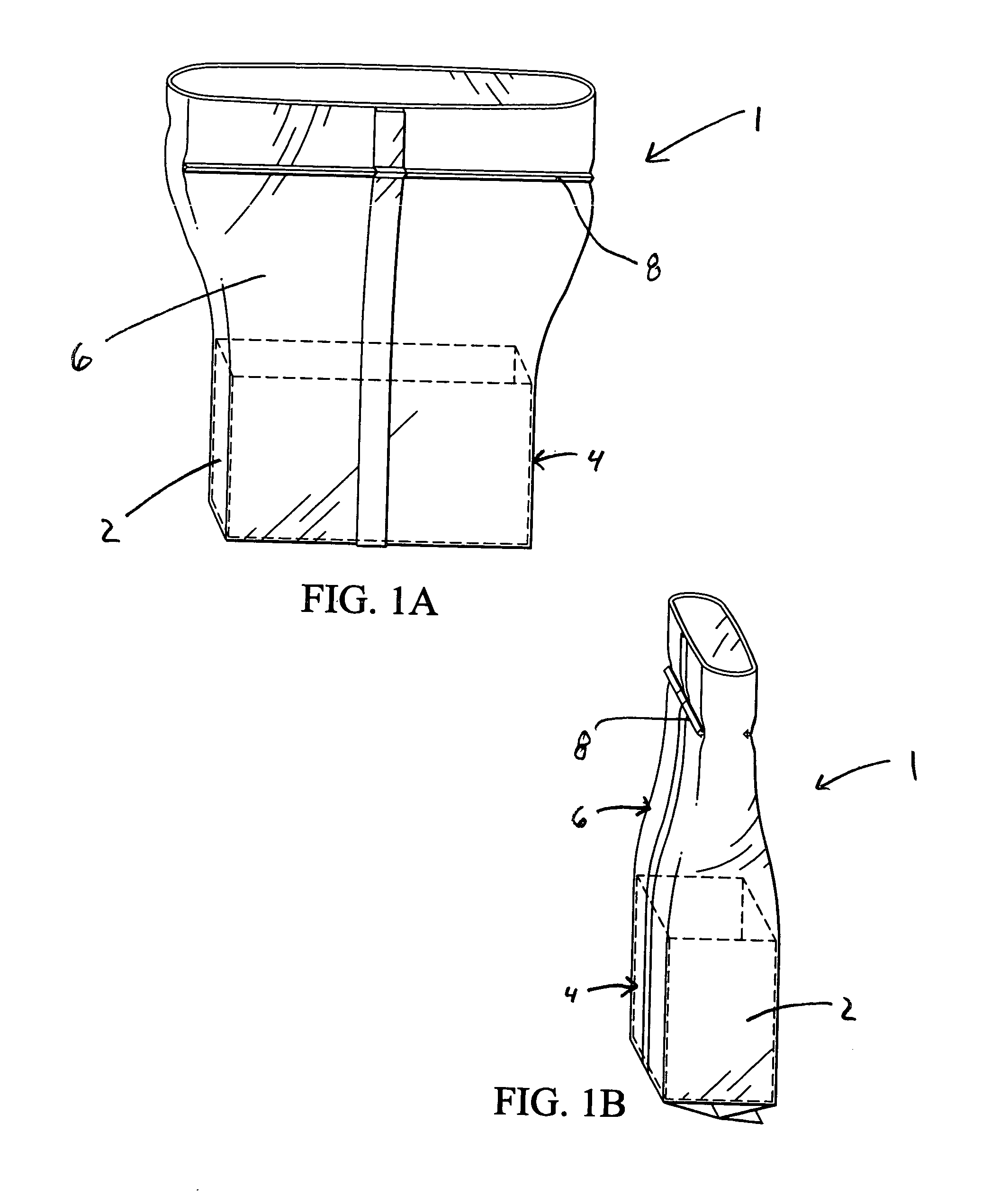

[0020] As shown in FIGS. 1A and 1B, a flexible package (bag 1) with a supportive structure 2 built into the package. The supportive structure 2 is appropriately formed and affixed to the lower portion 4 of bag 1 such that the bag encapsulates the support as shown. Preferably, the support for the supportive structure 2 is generally borne by the bag 1, and the supportive structure 2 fits snuggly therein such that the bag 1 fits around the exterior of the supportive structure 2 and substantially conforms to the shape and configuration of the supportive structure 2. The supportive structure 2 may be heat sealed, or the like, to bag 1 to ensure that supportive structure 2 is properly retained therein. The upper portion 6 of bag 1 may extend beyond the height of the support 2 such that the upper portion 6 of bag 1 is flexible and has the general characteristics of a bag without a support. For instance, the support may be 3½ inches in height, while the bag may extend upward beyond the top ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com