Complex optical element and method for manufacturing thereof

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

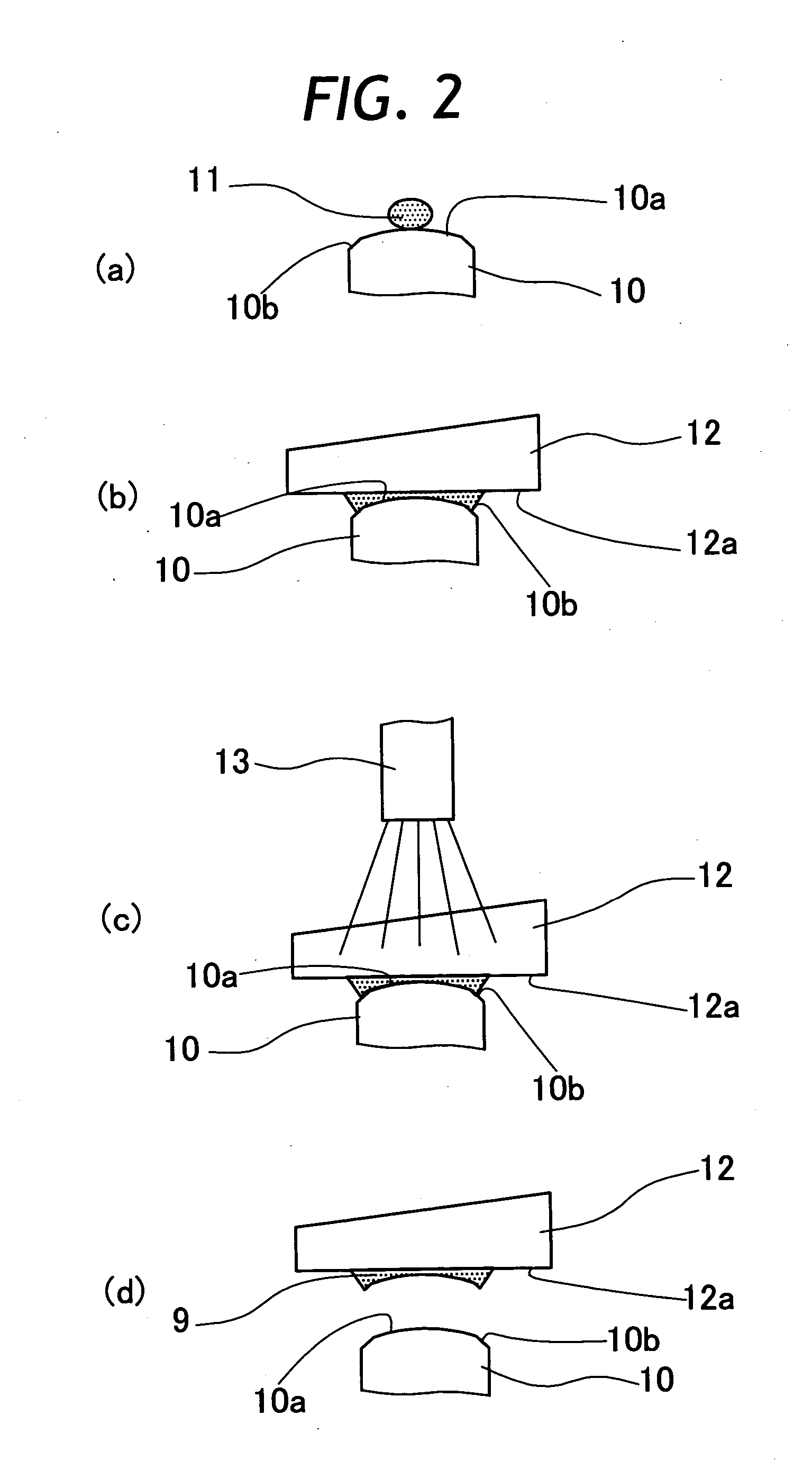

[0023] Hereafter, with reference to the accompanying drawings, the present invention is described more particularly by way of its preferred embodiments.

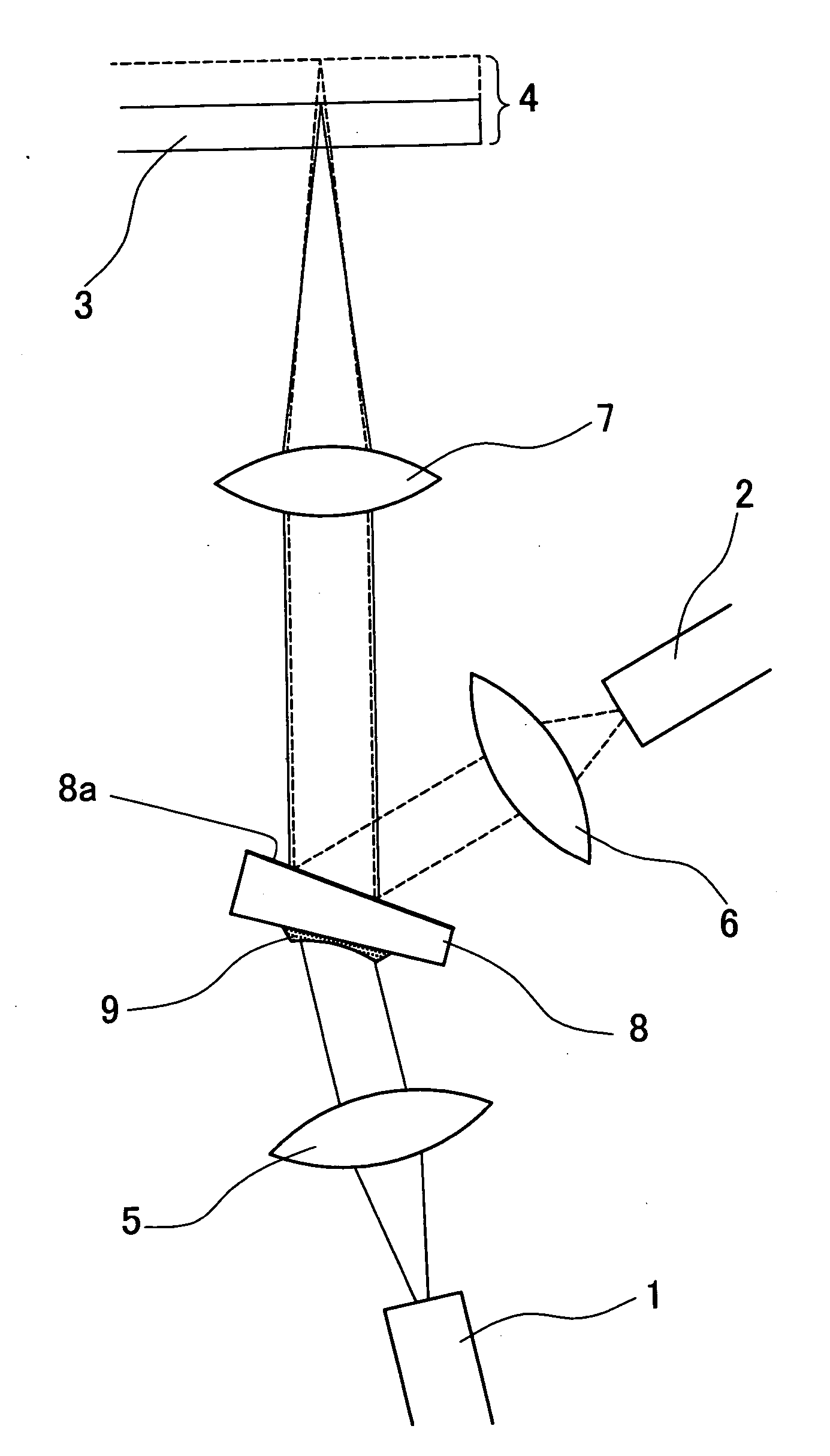

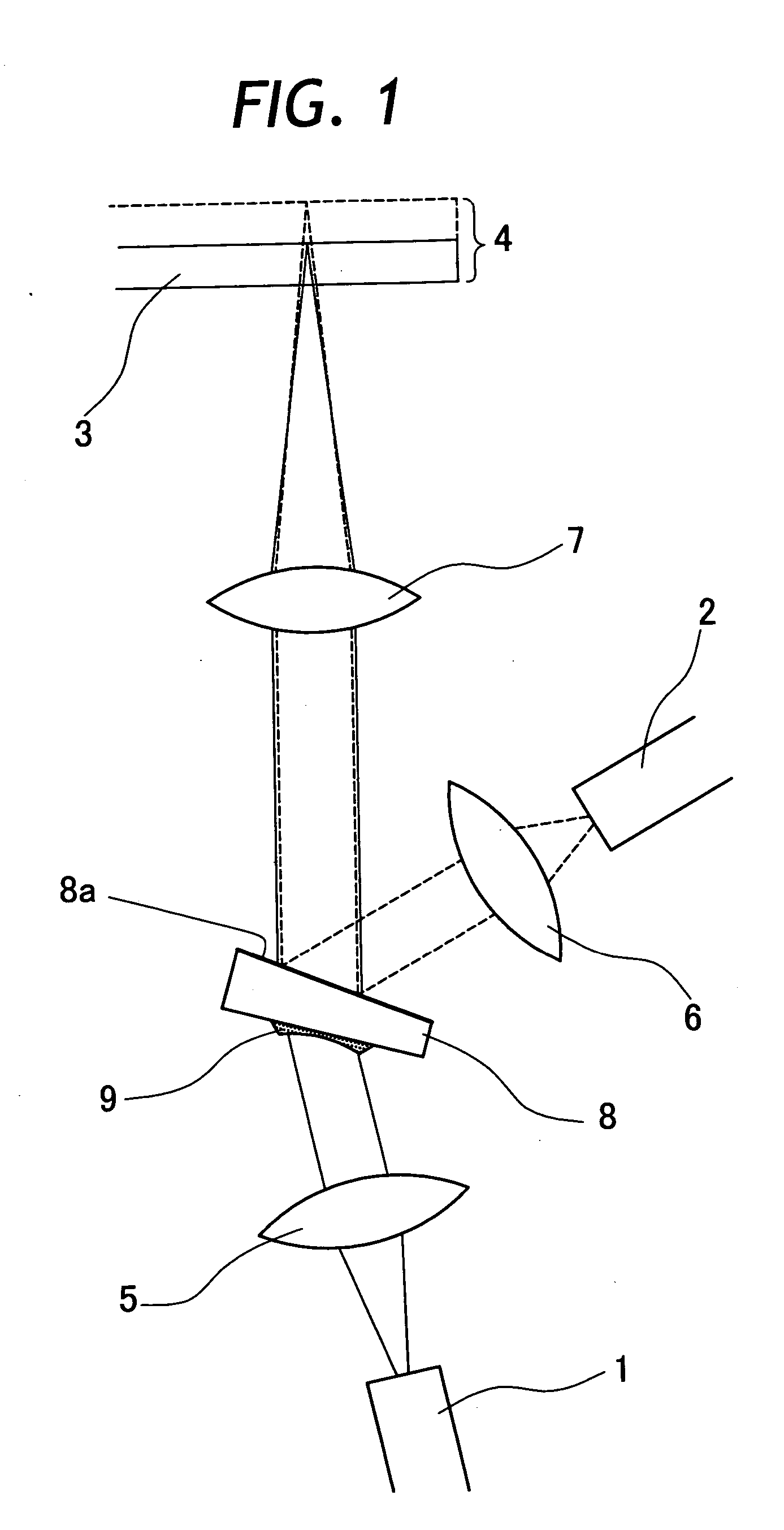

[0024] Referring to FIG. 1, there is shown a first embodiment of the present invention. In this first embodiment, a lens-laminated composite optical element is applied to an optical system of an optical disc pickup as schematically shown in FIG. 1. In FIG. 1, indicated at 1 is a first laser light source, and at 2 a second laser light source. A laser beam of 780 nm wavelength is projected from the first laser light source 1 to read information on a CD 3, while a laser beam of 650 nm wavelength is projected from the second laser light source 2 to read and write information on a DVD 4. The laser beams from the first and second laser light sources 1 and 2 are collimated through collimator lenses 5 and 6 and collimated light fluxes are converged toward CD 3 and DVD 4, respectively.

[0025] Indicated at 8 in FIG. 1 is a polarized prism, an...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Transmission | aaaaa | aaaaa |

| Transparency | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com