Laminated composites

a technology of laminated composites and elastic composites, which is applied in the field of laminated elastic composites, can solve the problems of inability to produce a single elastic composite that possesses all of them, and the same film has the disadvantage of being neither breathable nor conformable, and achieves the effect of adding tensile strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

example 1

Porous Elastic Wrap

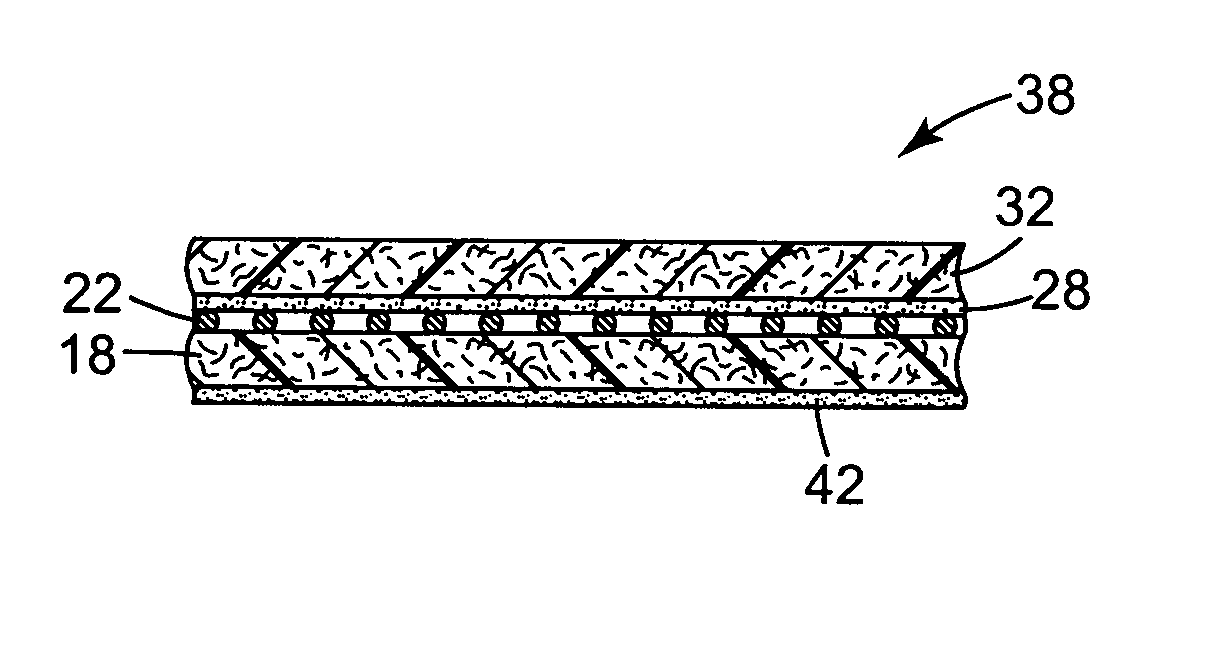

(Nonwoven / / BMF-PSA / / Filaments / / Nonwoven Laminate)

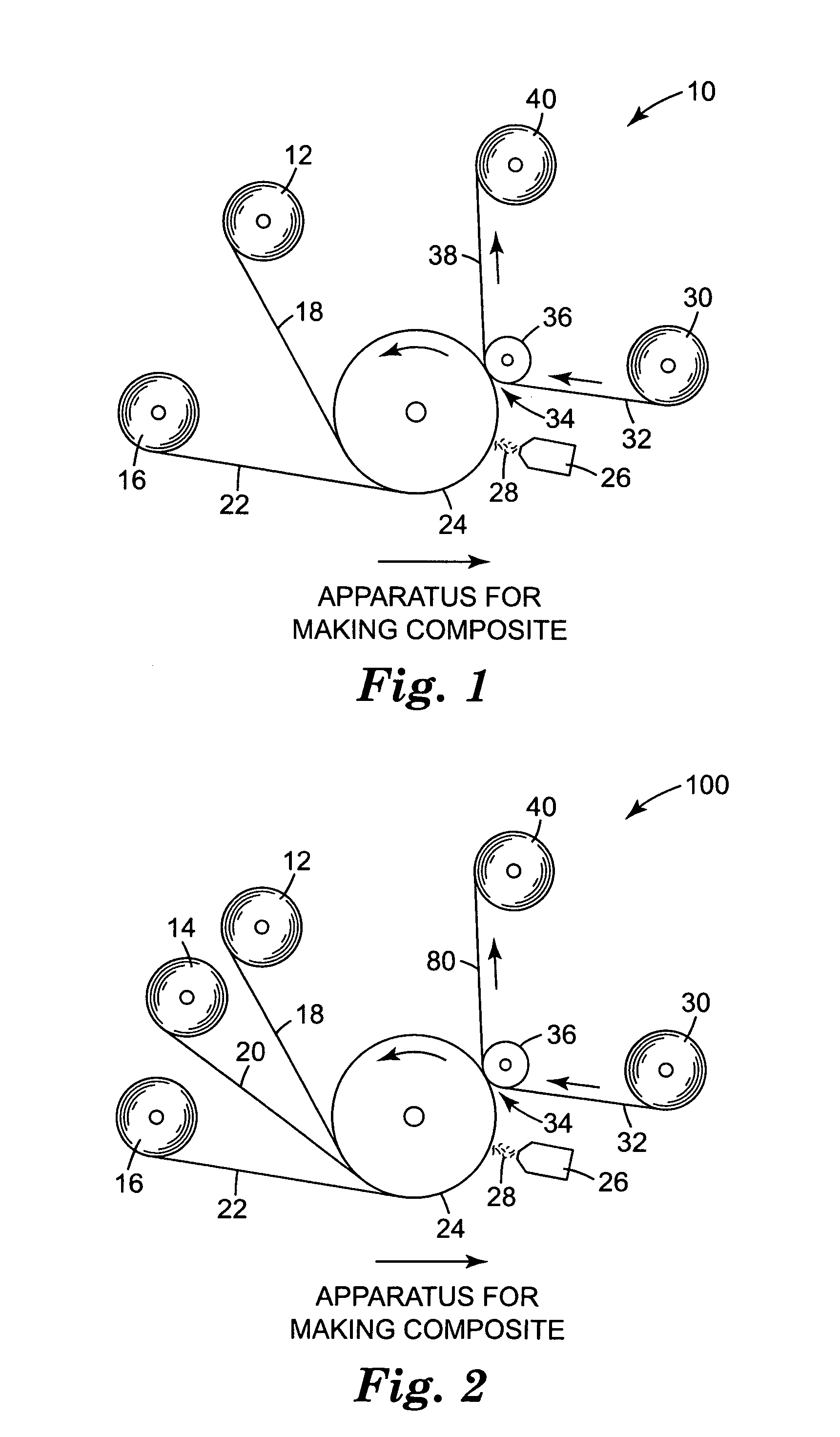

[0099] A porous elastic wrap comprising a laminate having nonwoven polypropylene outer layers, elastic filaments, and a melt blown adhesive was prepared according to the following process.

[0100] A melt blown fiber (BMF) pressure-sensitive adhesive (PSA) web comprised of three-layer polymeric fibers was prepared using a melt blowing process similar to that described, for example, in Wente, Van A., “Superfine Thermoplastic Fibers,” in Industrial Engineering Chemistry, Vol. 48, pages 1342 et seq. (1956) or in Report No. 4364 of the Naval Research Laboratories, published May 25, 1954, entitled “Manufacture of Superfine Organic Fibers” by Wente, Van A.; Boone, C. D.; and Fluharty, E. L., except that the BMF apparatus utilized two extruders, each of which fed its extrudate to a gear pump that controlled the polymer melt flow. The gear pumps fed a three-layer feedblock (splitter) assembly similar to that described in U....

example 2

Porous Elastic Wrap

(Nonwoven / / BMF-PSA / / Filaments / / Nonwoven Laminate)

[0103] A porous elastic wrap was prepared according to the process described in Example 1, except that two layers of polyester spunlaced nonwoven (34 g / m2 basis weight, Product No. 5601, PGI Nonwovens, Mooresville, N.C.) were substituted for the two polypropylene spunbond nonwoven layers. The shirred elastic laminate was very soft in feel and was observed to adhere very well to the “hook side” of a mechanical fastener, for example, Hook XMH-4132 (Minnesota Mining and Manufacturing Company, St. Paul, Minn.). Samples of the laminate were cut for subsequent test evaluations.

example 3

Porous Elastic Wrap

(Nonwoven / / BMF-PSA / / Filaments / / Scrim / / Nonwoven Laminate)

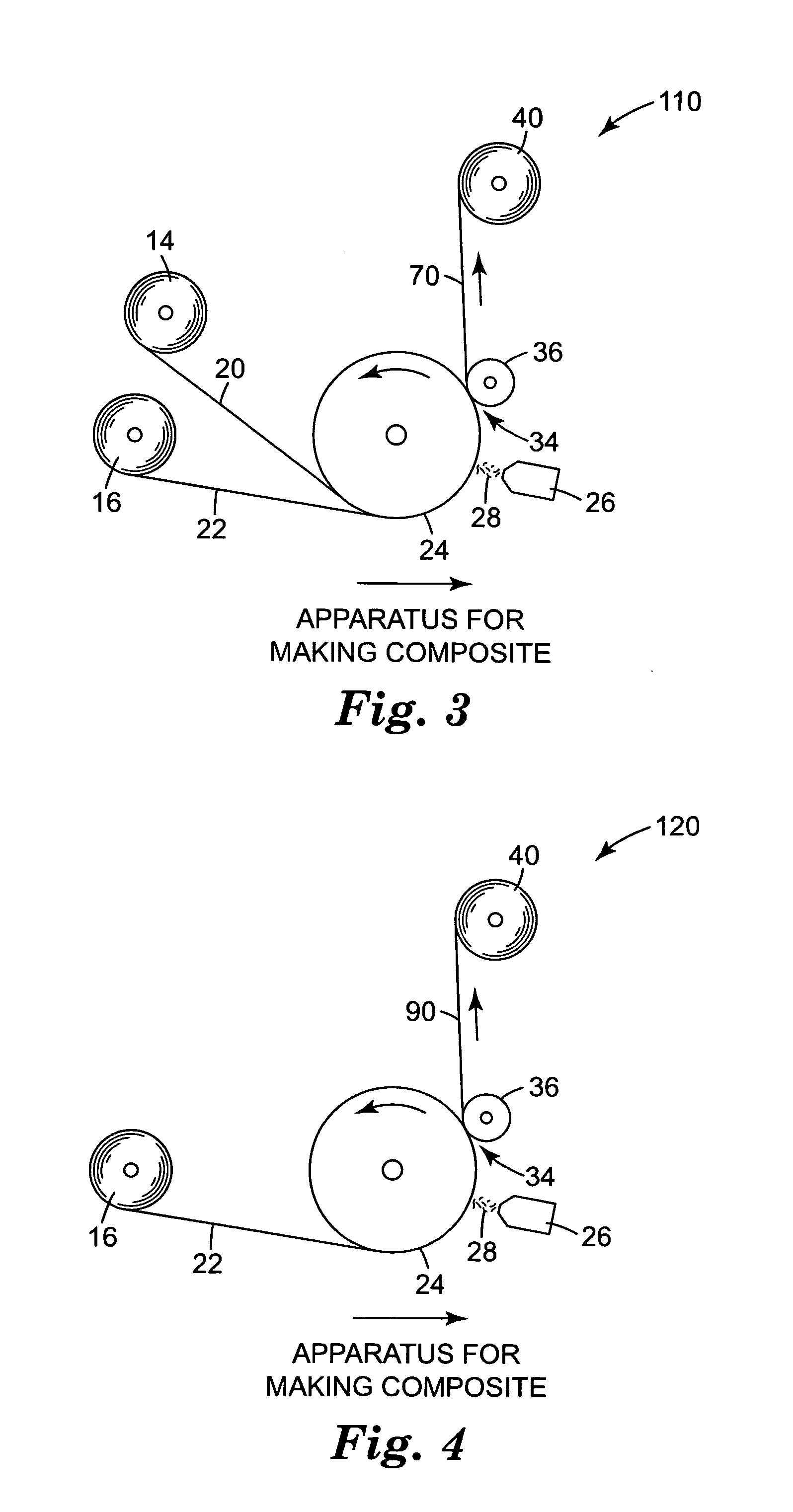

[0104] A porous elastic wrap was prepared according to the process described in Example 1, except that a weft-inserted polyester scrim layer with 18 yarns / 2.5-cm (40 denier, machine-direction) and 9 yarns / 2.5-cm (150 denier, cross-direction) (Product No. 924864, Milliken Company, Spartanburg, S.C.) was inserted between the first layer of polypropylene spunbond nonwoven and the elastic filaments layer. The three layers were wrapped around the collector drum and conveyed in front of the BMF die at a collector-to-die distance of 12.7 cm. The BMF-PSA web was blown onto the filaments side of the composite to bind the scrim and stretched filaments to the nonwoven. This composite was then transported approximately 38.1 cm to a nip point where another layer of polypropylene spunbond nonwoven was brought into contact with the BMF-PSA side of the construction. A nip force of 551 N was applied across a 51-cm width of ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

| Fraction | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com