Cover for hot tub, spa, or the like

a technology for hot tubs and covers, applied in the field of covers for spas and hot tubs, can solve the problems of reducing the likelihood that a child with a break the cover, and achieve the effects of improving the static load capacity of the cover, reducing the likelihood of sagging, and increasing load bearing capabilities

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

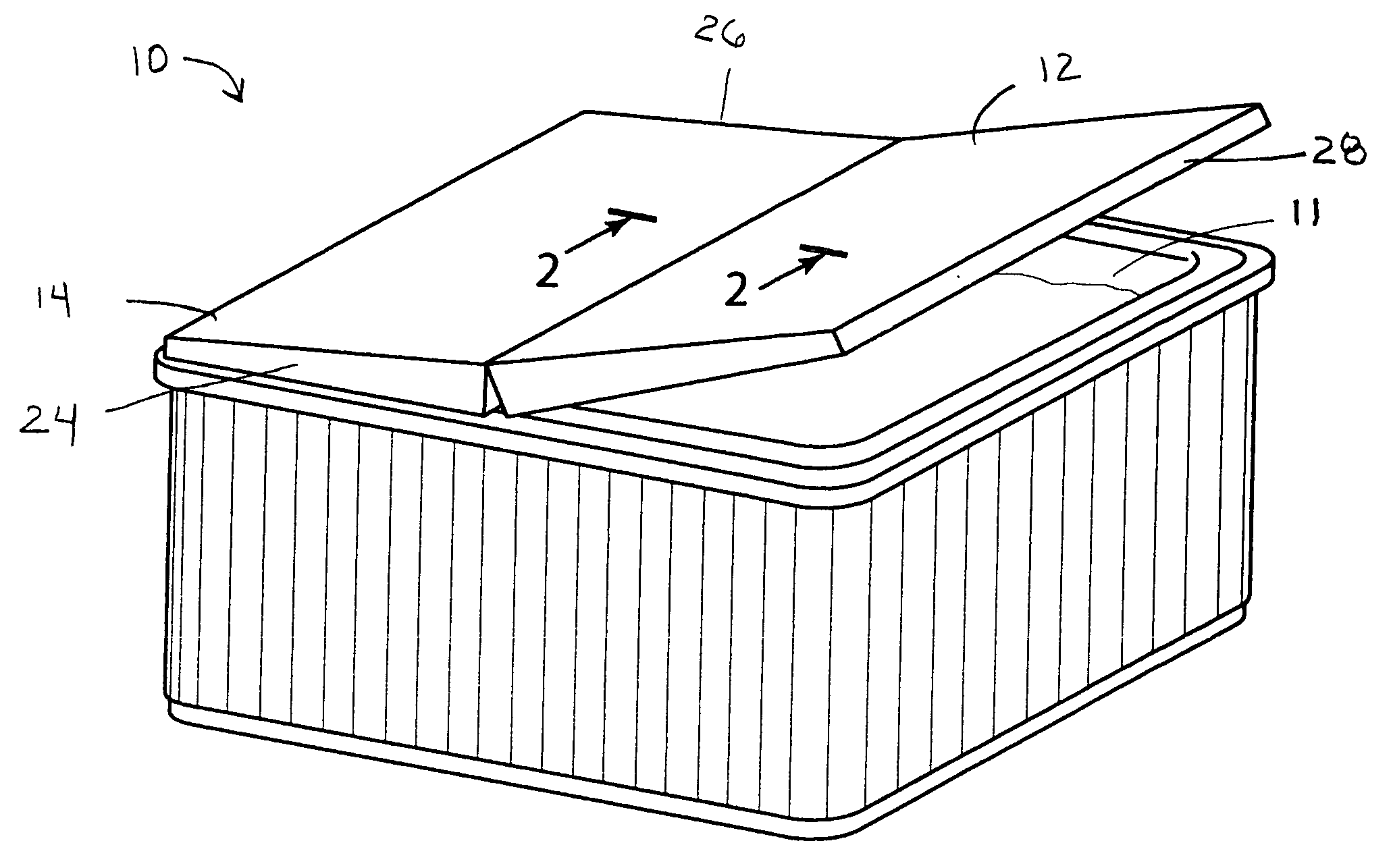

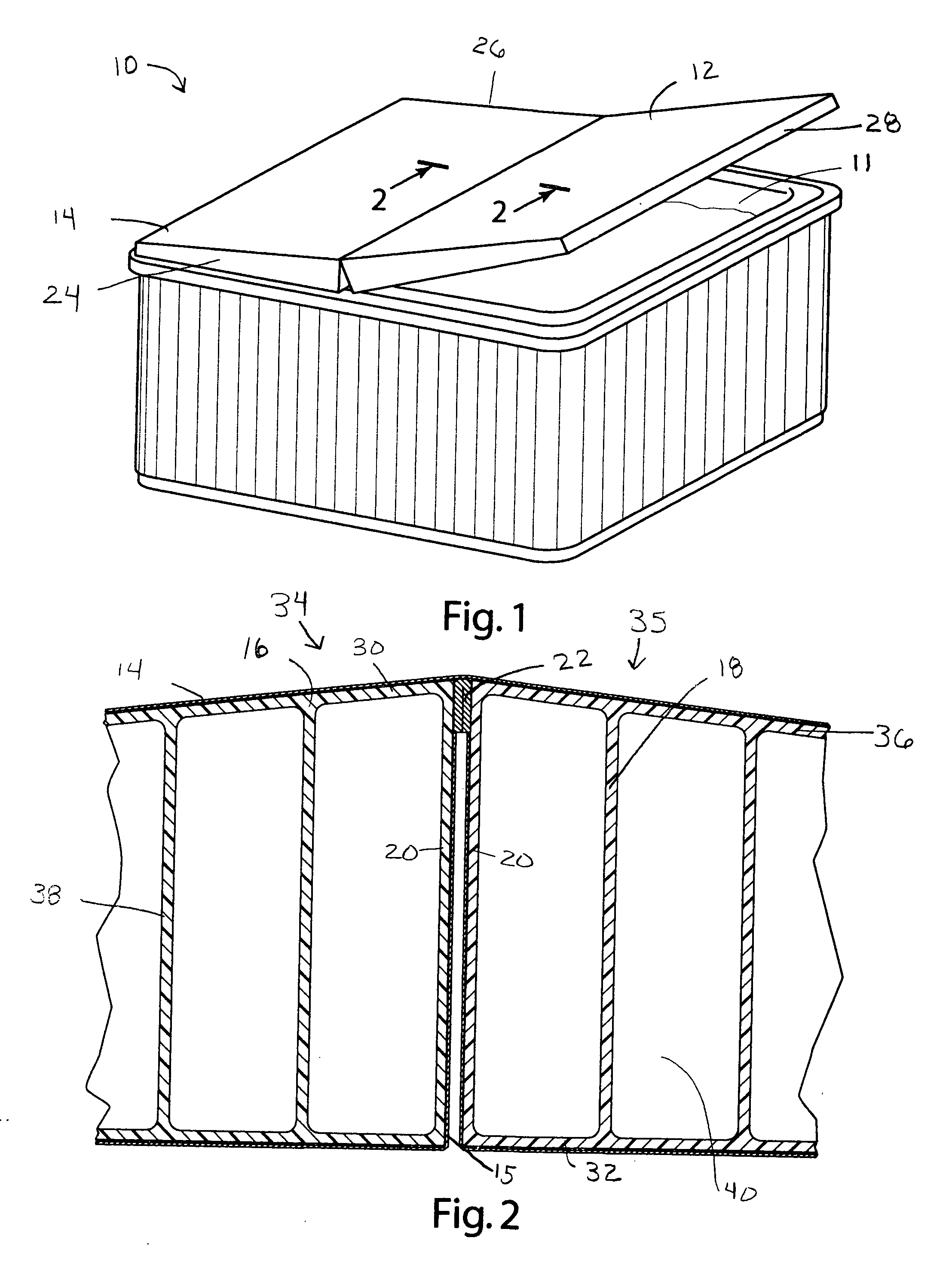

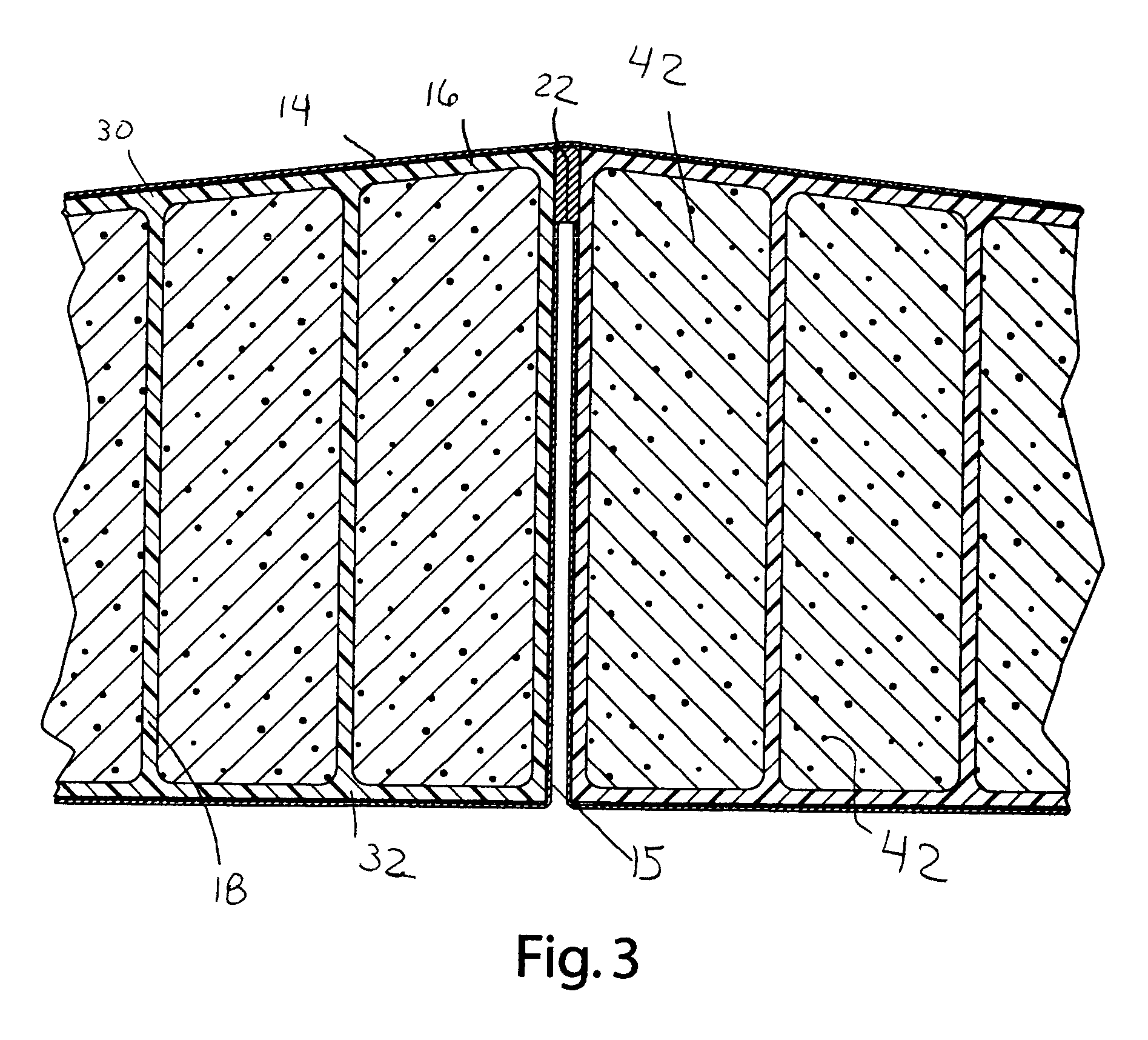

[0013] A hot tub in accordance with the preferred embodiment is shown in FIG. 1 and generally designated 10. It should be understood that the hot tub 10 may be rectangular (as shown) or any other desired shape. The cover 12 fits over the entire opening 11 of the hot tub 10. The cover 12 generally includes a vinyl jacket 14 and a plastic core insert 16. The vinyl jacket 14 encloses the core 16 and is conventionally sealed around the core 16. The core insert 16 includes a hinge 22 that allows the cover 12 to fold onto itself. The core insert 16 tapers from the hinge towards the periphery and includes a plurality of strengthening ribs 18.

[0014] The jacket 14 is well known and generally made of a marine grade vinyl, or another high-strength waterproof fabric. The jacket 14 is large enough to fit over a rigid core 16, and includes a front edge 24, rear edge 26, and an outer edge 28. In a preferred embodiment, the jacket 14 is capable of being sealed to completely enclose the core 16 by ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com