Tunable filter membrane structures and methods of making

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

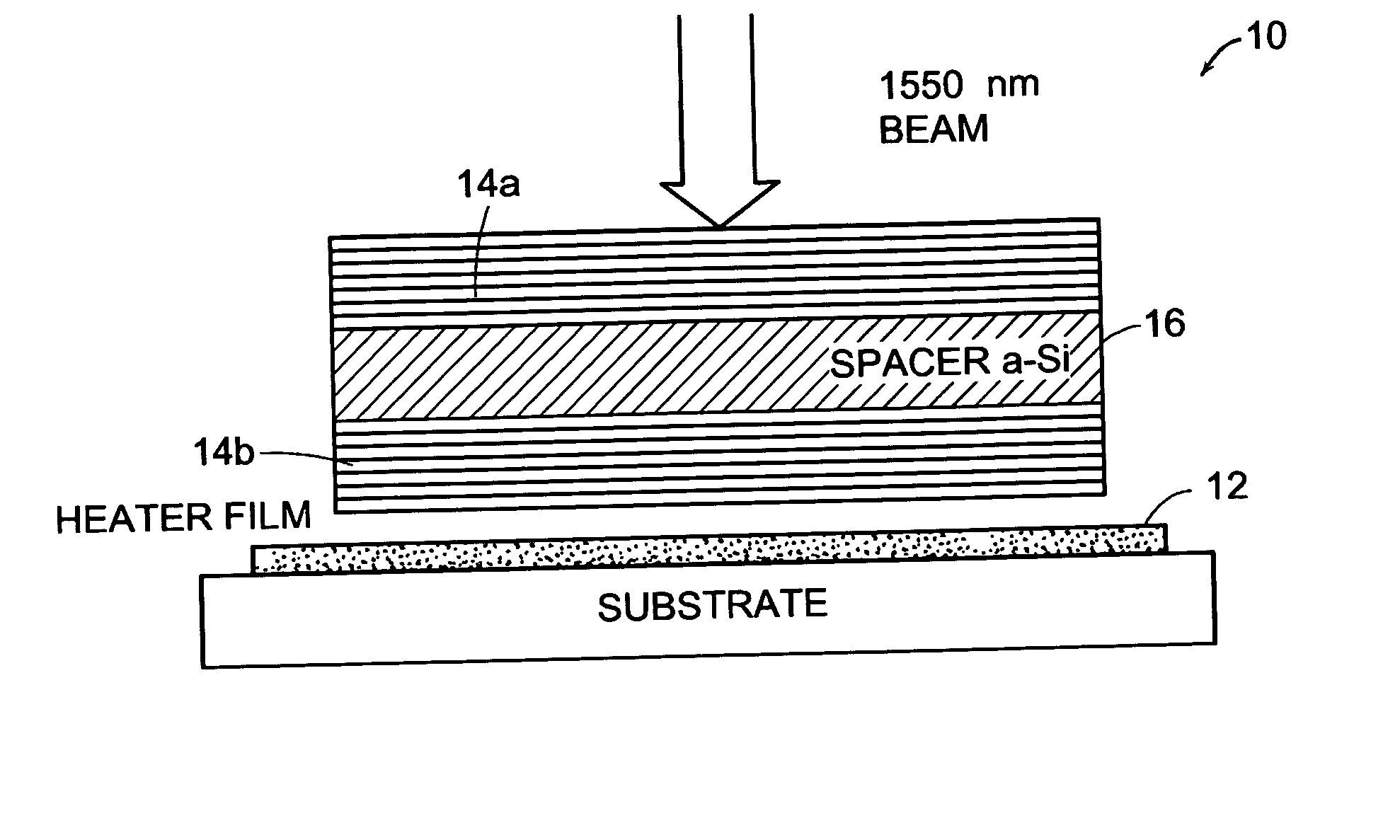

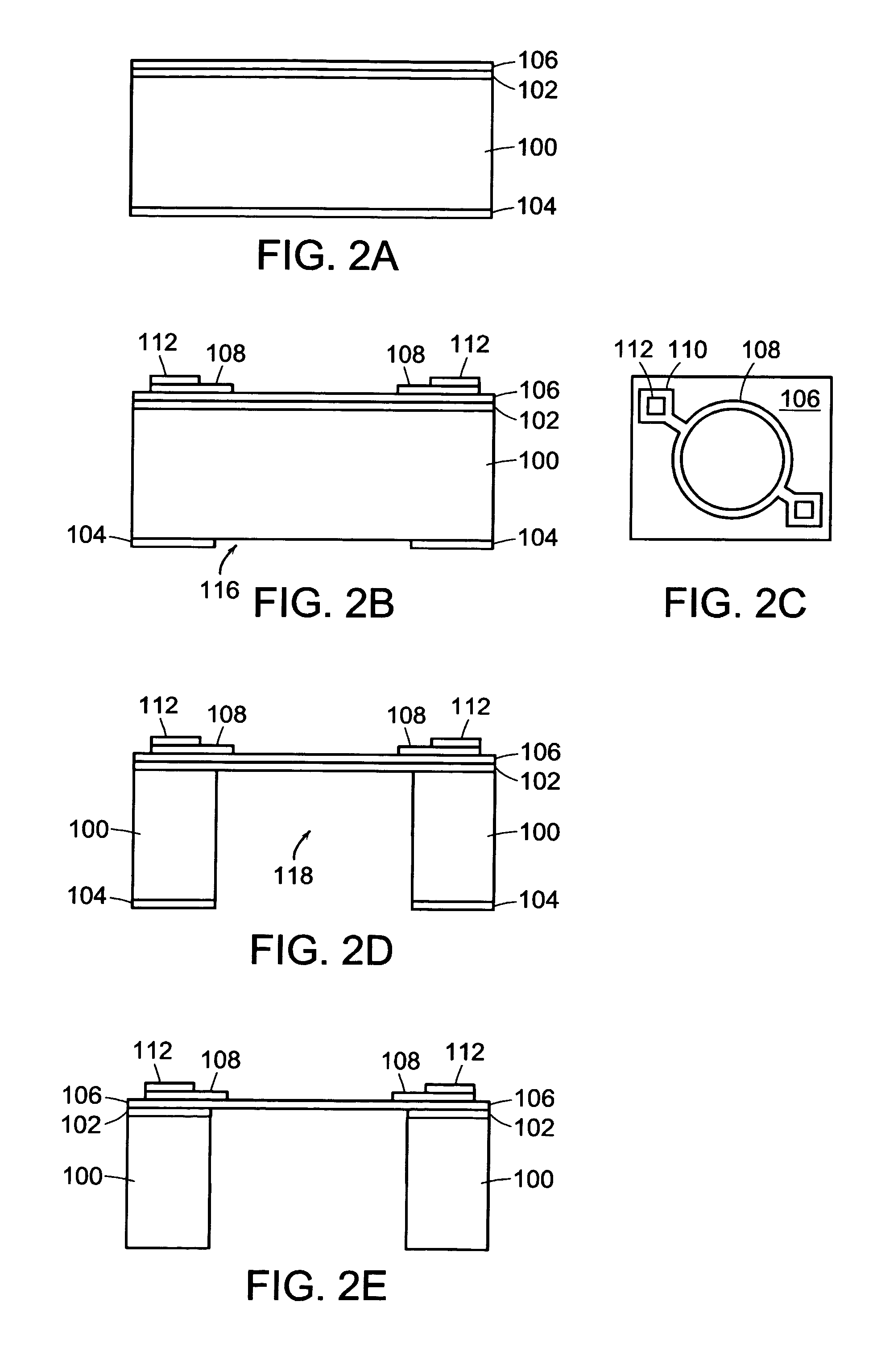

[0024] Simple Membrane Structure:

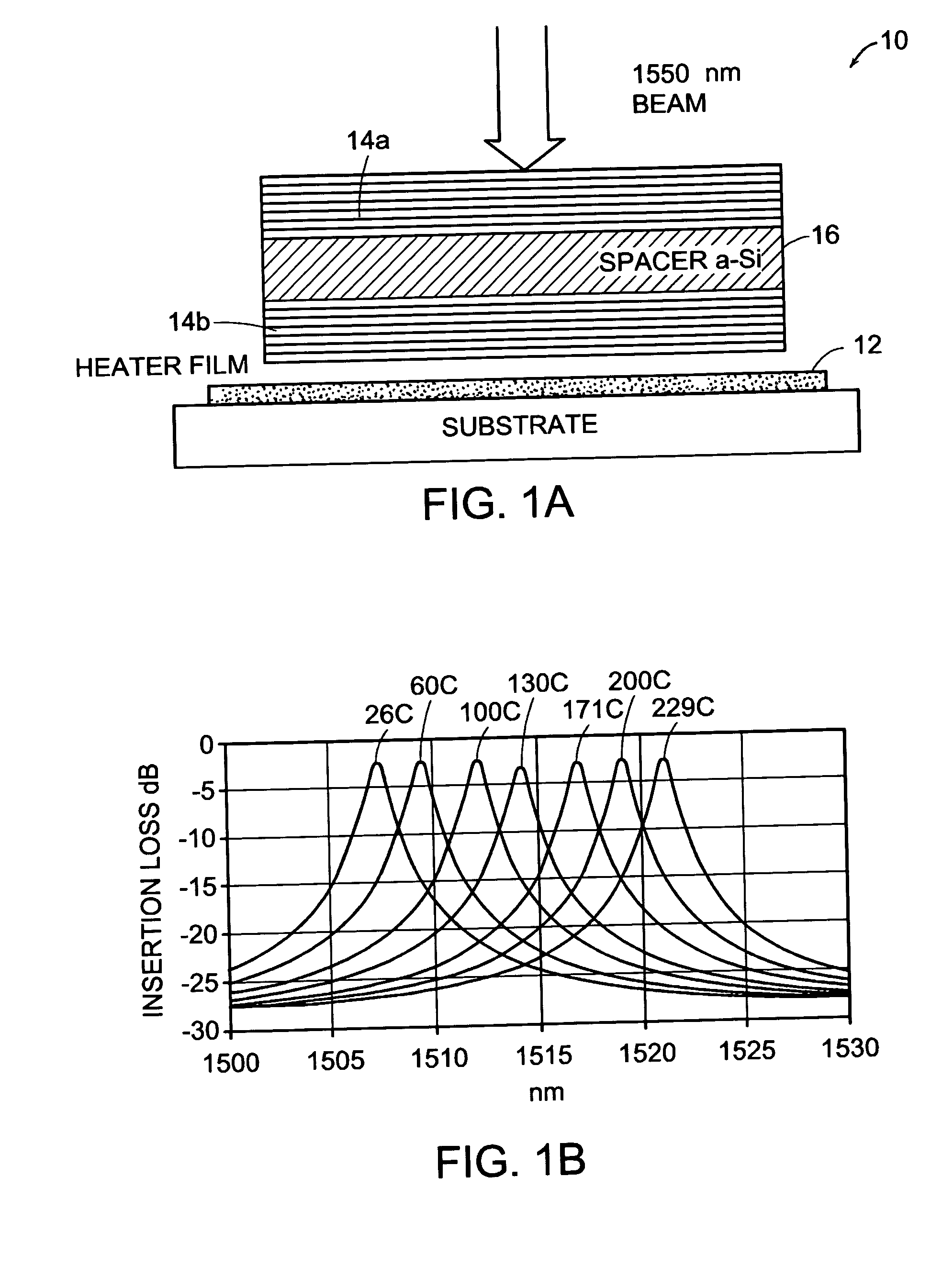

[0025] The first embodiment is a thermo-optically tunable filter formed as a membrane on a silicon frame. The tunable filter which makes up the membrane is fabricated as described in previously filed applications and published articles. In general, it is a multi-layer thin film structure that includes one or more Fabry-Perot cavities, each of which has two thin film interference mirrors separated by a spacer. The mirrors and the spacers are made of a material that has an index of refraction that is characterized by a relatively high thermal coefficient. In this case, that material is amorphous silicon (a-Si), though other materials could also be used such as amorphous germanium (a-Ge). The resulting optical filter has a optical transmission curve with a band pass located at a wavelength that is determined by the design of the structure, e.g. the thickness of the films that make up the multi-cavity structure. By heating and cooling the optical filter...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com