Green roof blocks

a technology of green roof and roof panels, applied in the field of green roof panels, can solve the problems of increasing weight, high price of typical green roof construction, and high cost of typical green roof construction, and achieve the effects of convenient placement on the roof, quick and inexpensive, and easy movemen

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

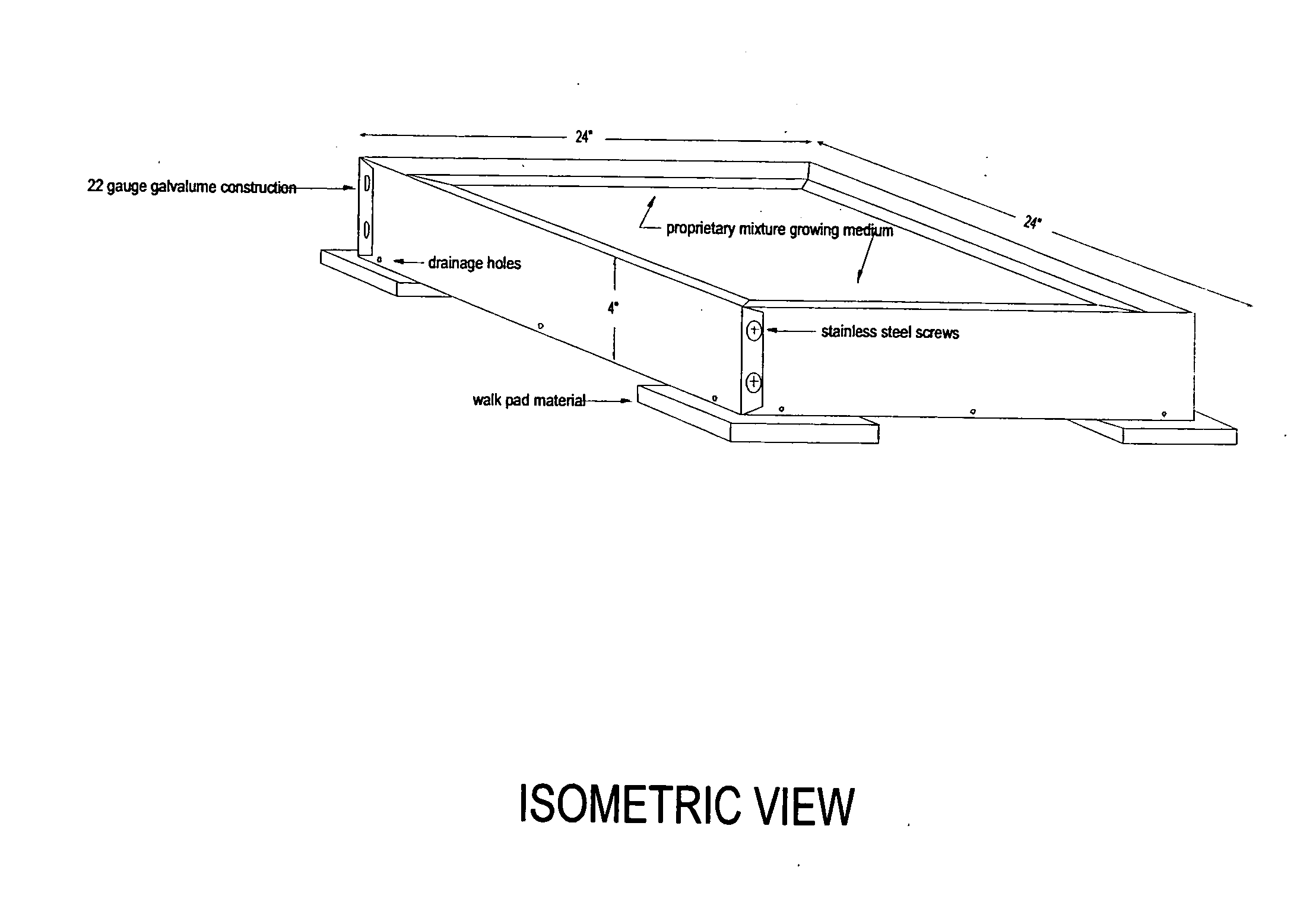

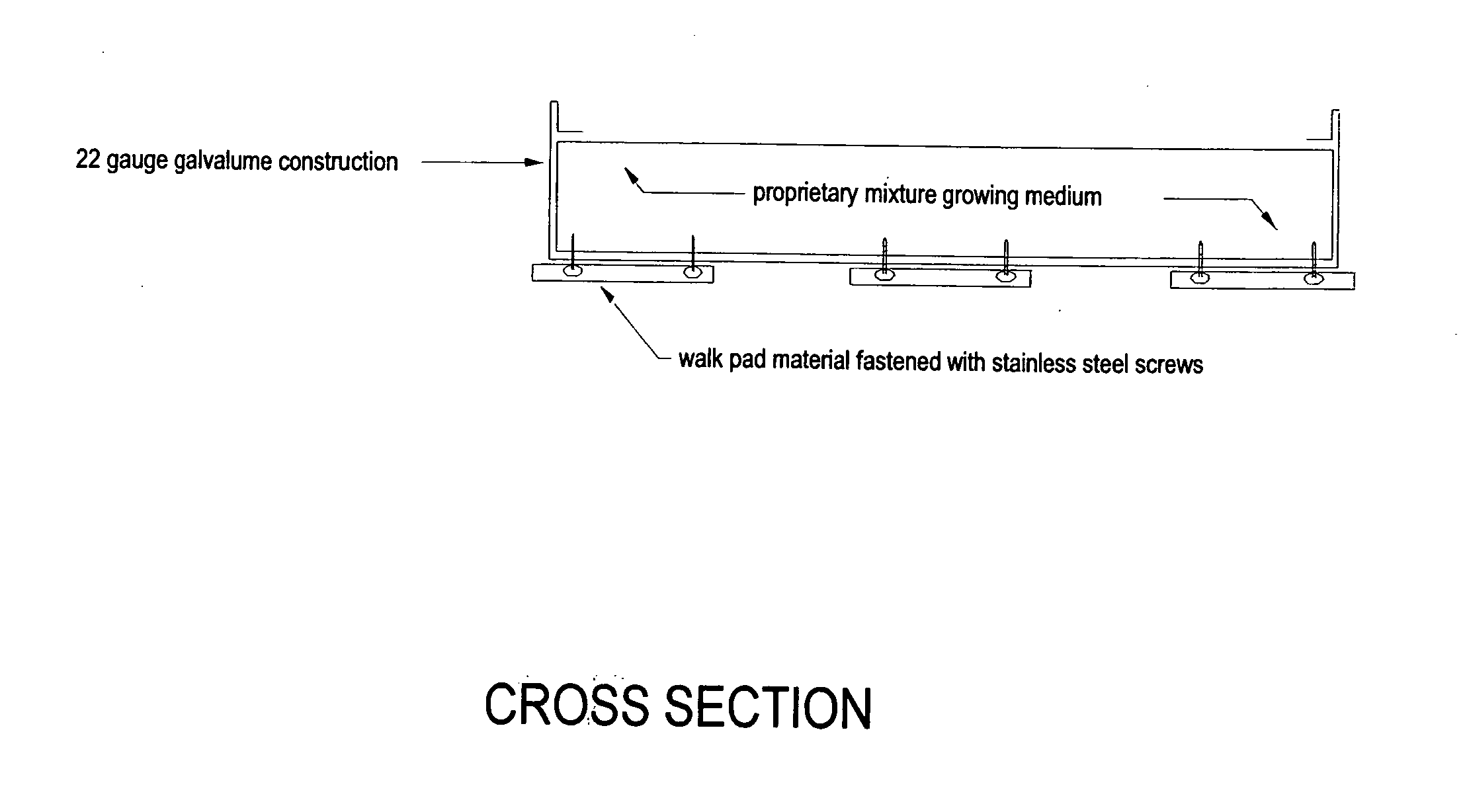

[0006] This invention, Green Roof Blocks, is constructed in a completely original manner, using unique materials for the container and the growing medium. Green Roof Blocks are a self contained roof greening product made from the following components; organic soils, mineral particulate, Sedum Kamtschaticum plants, 22 gauge galvalume sheet metal, stainless steel screws, rubber composite roofing walk pad material. A Container constructed of 22 gauge galvalume sheet metal sized 24 inches by 24 inches and 4 inches in depth, is filled with 80% mineral (haydite) and 20% organic growing medium, and four sedum kamtschaticum seedlings are planted six inches from each side. The box construction is fabricated from flat sheet metal material cut from a 35.5 inch square section. Though the product is prepared for fabrication utilizing a custom machined punch press to cut the desired shape, the following procedure can be used to cut the material by hand using a pair of quality tin snips. Lines at ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com