Portable ultrasonic cleaner

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

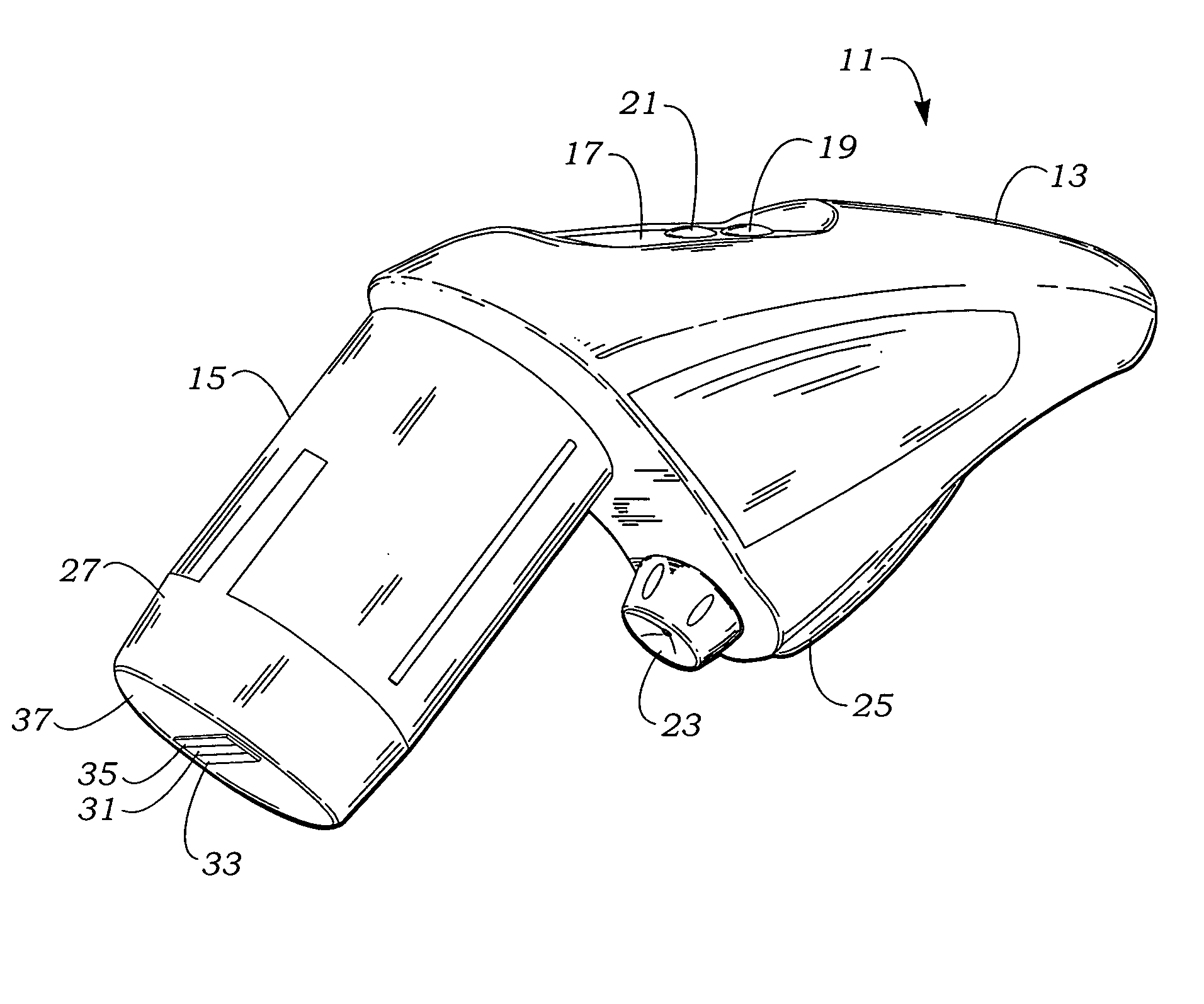

[0017] The description and operation of the invention will be best initiated with reference to FIG. 1 and which illustrates a portable ultrasonic cleaner 11 as an integrated unit having a rear housing section 13 and a front housing section 15. The rear housing section 13 is shaped for comfortable one-hand utilization, and includes a control panel 17 and may have an on / off switch 19 and power indicator 21.

[0018] The lower area of the rear housing section 13 may have an optional solvent / detergent spray nozzle 23 actuated by a pump handle 25. Other methods of delivery of fluid media may be utilized, and the overall area of the portable ultrasonic cleaner housing may be reduced with the optional elimination of the lower solvent / detergent reservoir and delivery mechanism.

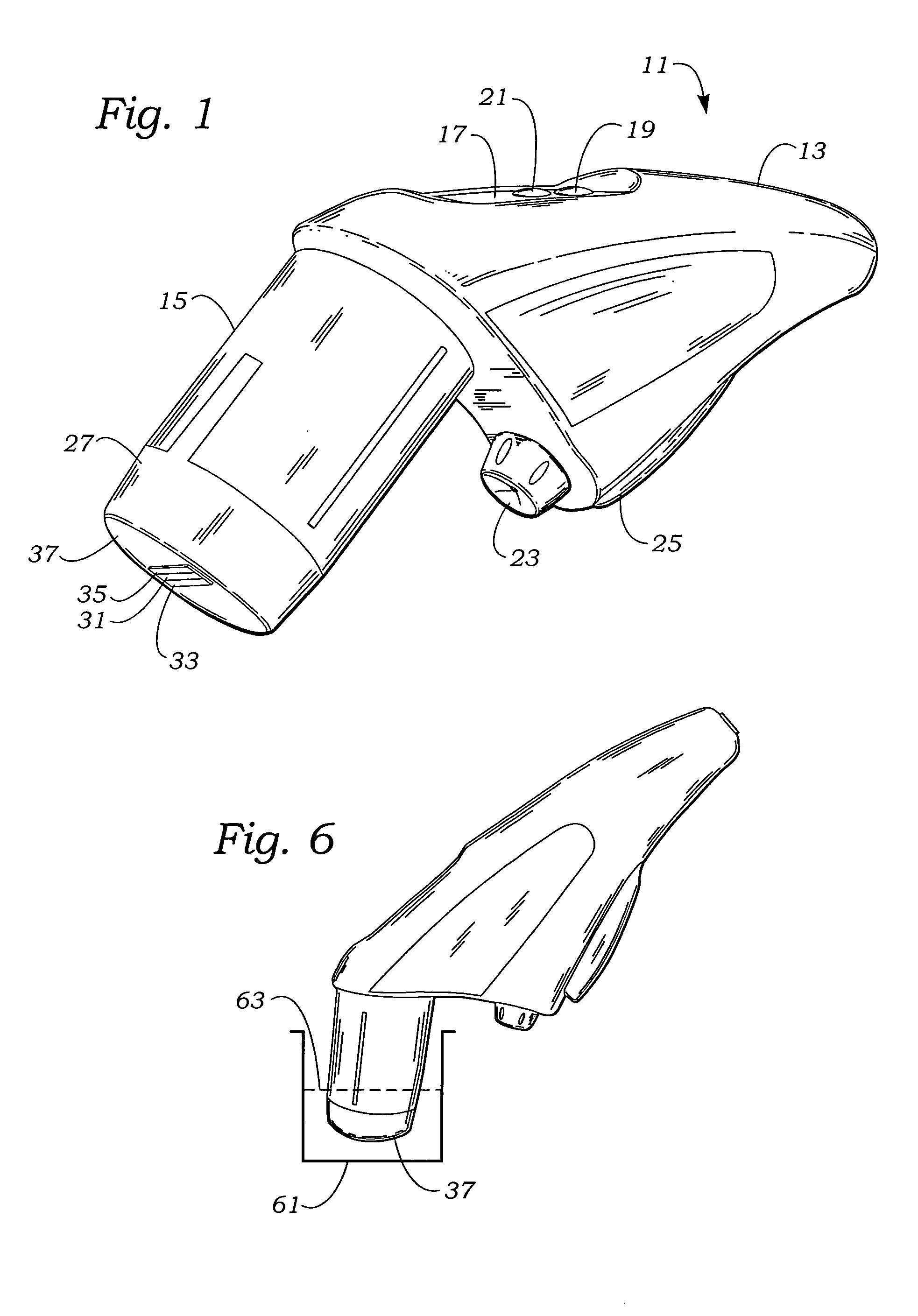

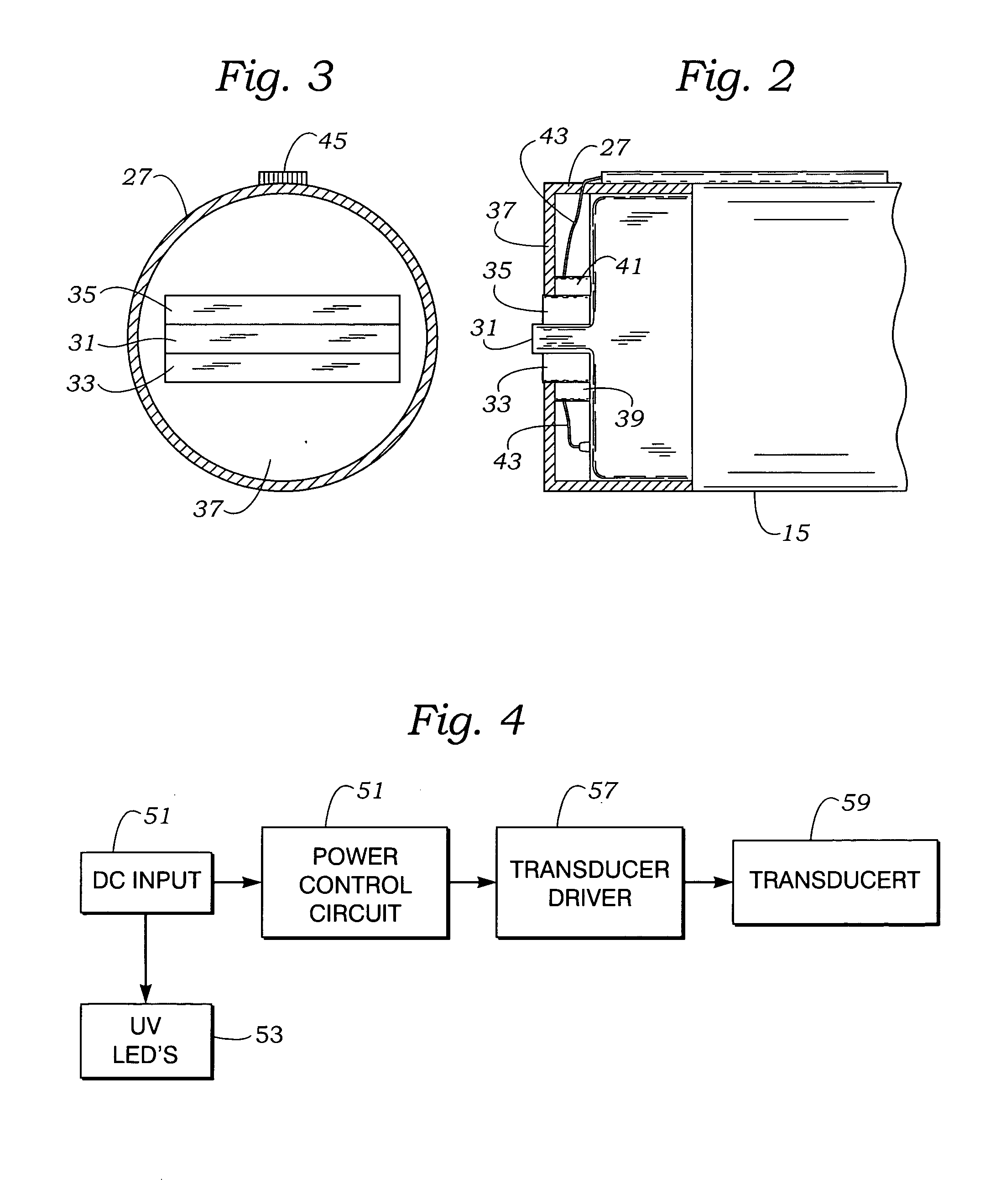

[0019] The front housing section 15 includes a detachable cap 27 to facilitate cleaning and service of the working face components should these components be contaminated by solvent, detergent, or other materials. At t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com