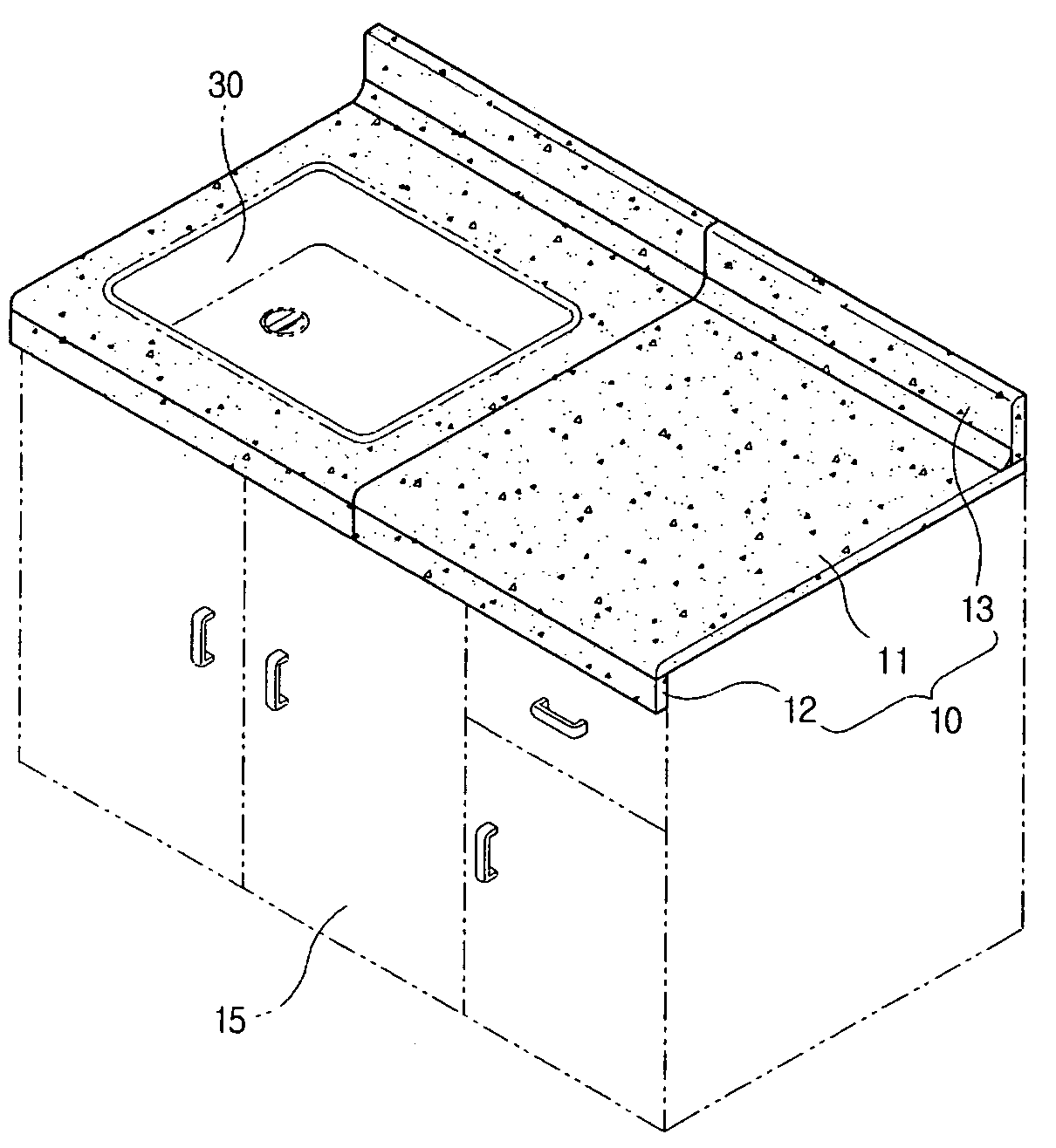

Method of manufacturing solid surface counter top

a manufacturing method and counter top technology, applied in the field of manufacturing solid surface counter tops, can solve the problems of inconvenient manufacturing, long time to complete a product, inconvenient manufacturing, etc., and achieve the effect of rapid product manufacturing and simplified manufacturing process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

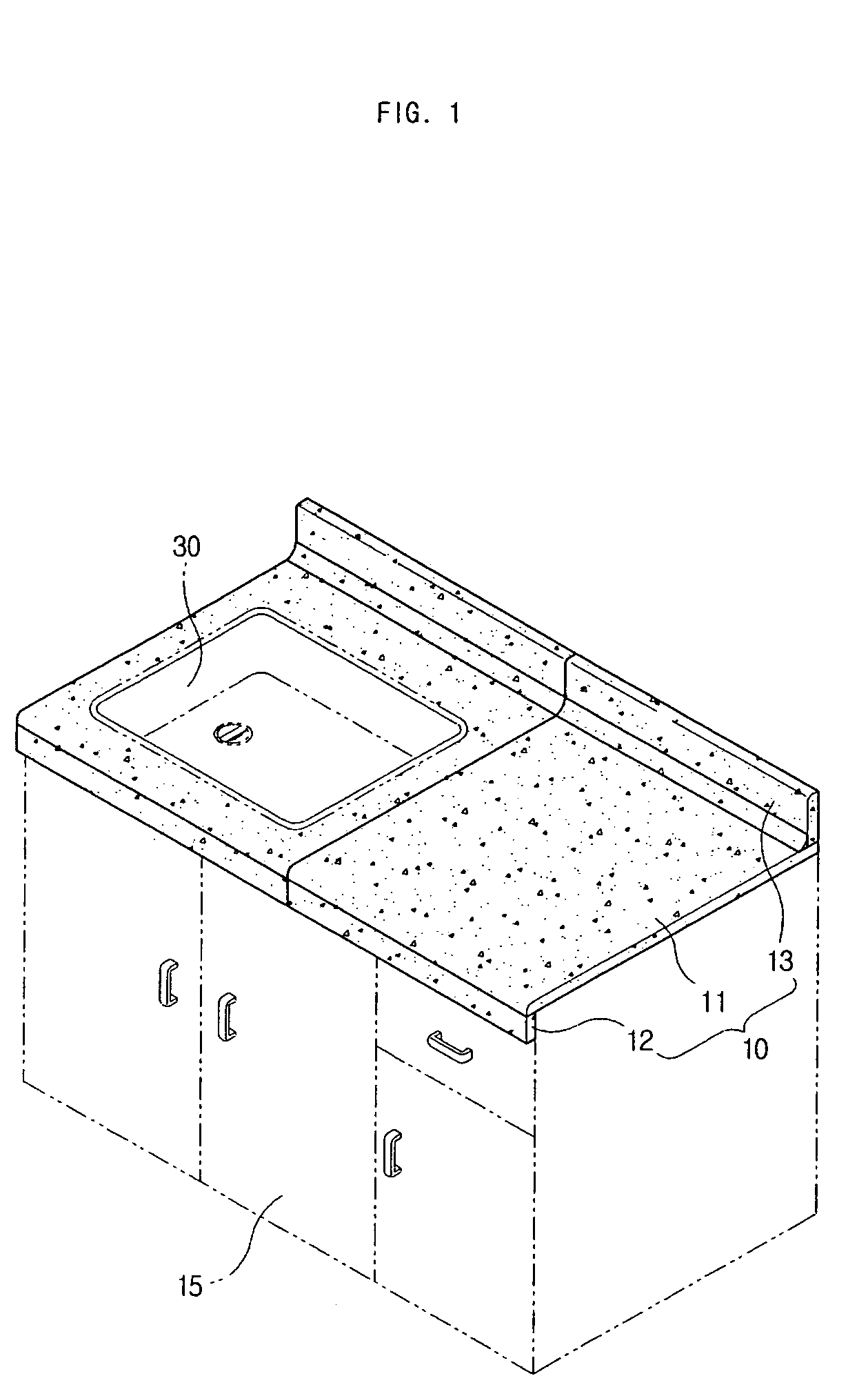

Embodiment Construction

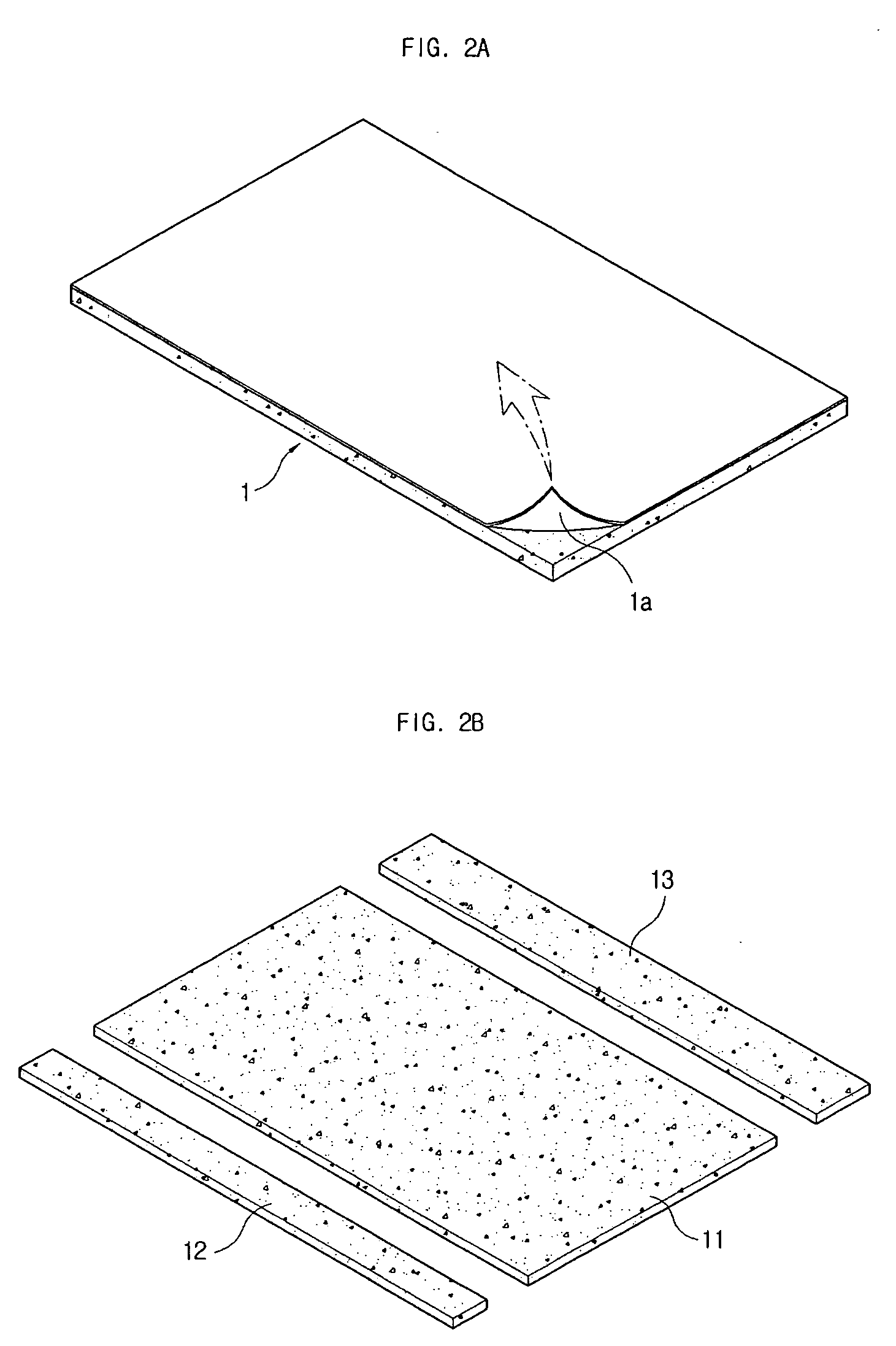

[0020] Referring to FIGS. 4A through 4E, in a method of manufacturing a solid surface counter top according to a first preferred embodiment of the present invention, first, an raw-material sheet 100 is prepared for manufacturing a solid surface counter top. A protection film 100a for preventing a glossy surface from scratches is attached to the raw-material sheet 100, as shown in FIG. 4A. In the present invention, the raw-material sheet 100 is processed without detaching the protection film 100a.

[0021] The processing is performed at a surface opposite to the glossy surface where the protection film 100a is attached. As shown in FIG. 4B, a groove 130a having a “T” shape is formed between the flat panel portion 110 and the backsplash 130 while a groove 120a having an angled “T” shape is formed between the flat panel portion 110 and the edge 120. Connection portions 120b and 130b having a fine thickness are left on the grooves 120a and 130a, respectively, so that the respective portio...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Shape | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com