Burner and method for the manufacture of synthetic quartz glass

Inactive Publication Date: 2005-06-23

SHIN ETSU CHEM CO LTD

View PDF6 Cites 31 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

[0017] An object of the invention is to provide a burner for use in the manufacture of synthetic quartz glass ingots which serve as the stock material from which synthetic quartz glass members having high optical homogeneity useful as optical parts such as lenses, prisms, windows and photomask-forming quartz glass substrates in excimer laser systems can be readily obtained or synthetic quartz glass members for liquid crystal-related large size glass substrates can be efficiently obtained. Another object is to provide a method for the manufacture of synthetic quartz glass ingots using the burner.

Problems solved by technology

This is a serious problem when quartz glass is used as a transmissive material for ArF and KrF excimer lasers.

In addition to the essential uniformity of refractive index, a reduction of birefringence becomes a crucial problem.

The situation is detrimental in production yield and efficiency.

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

example

[0061] The following examples are provided to illustrate the invention, and are not intended to limit the scope thereof. It is noted that in Examples, an internal transmittance was measured by ultraviolet spectrophotometry (Cary 400 by Varian Corp.).

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

| Property | Measurement | Unit |

|---|---|---|

| Fraction | aaaaa | aaaaa |

| Fraction | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Login to View More

Abstract

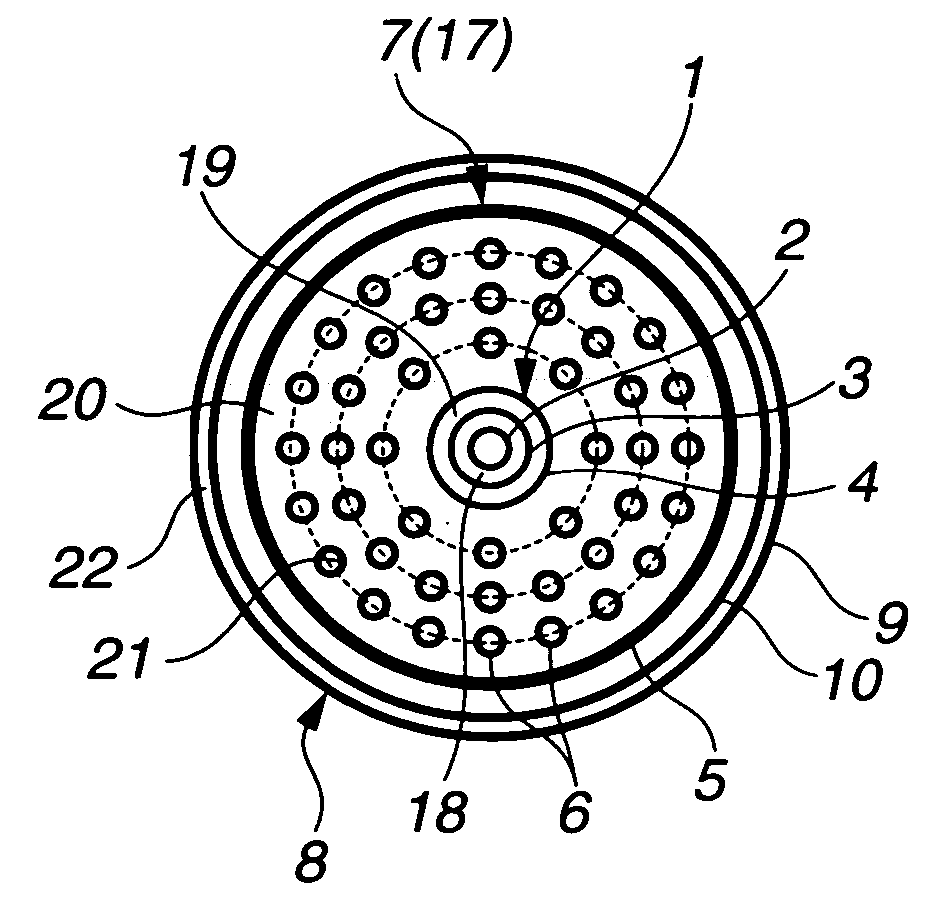

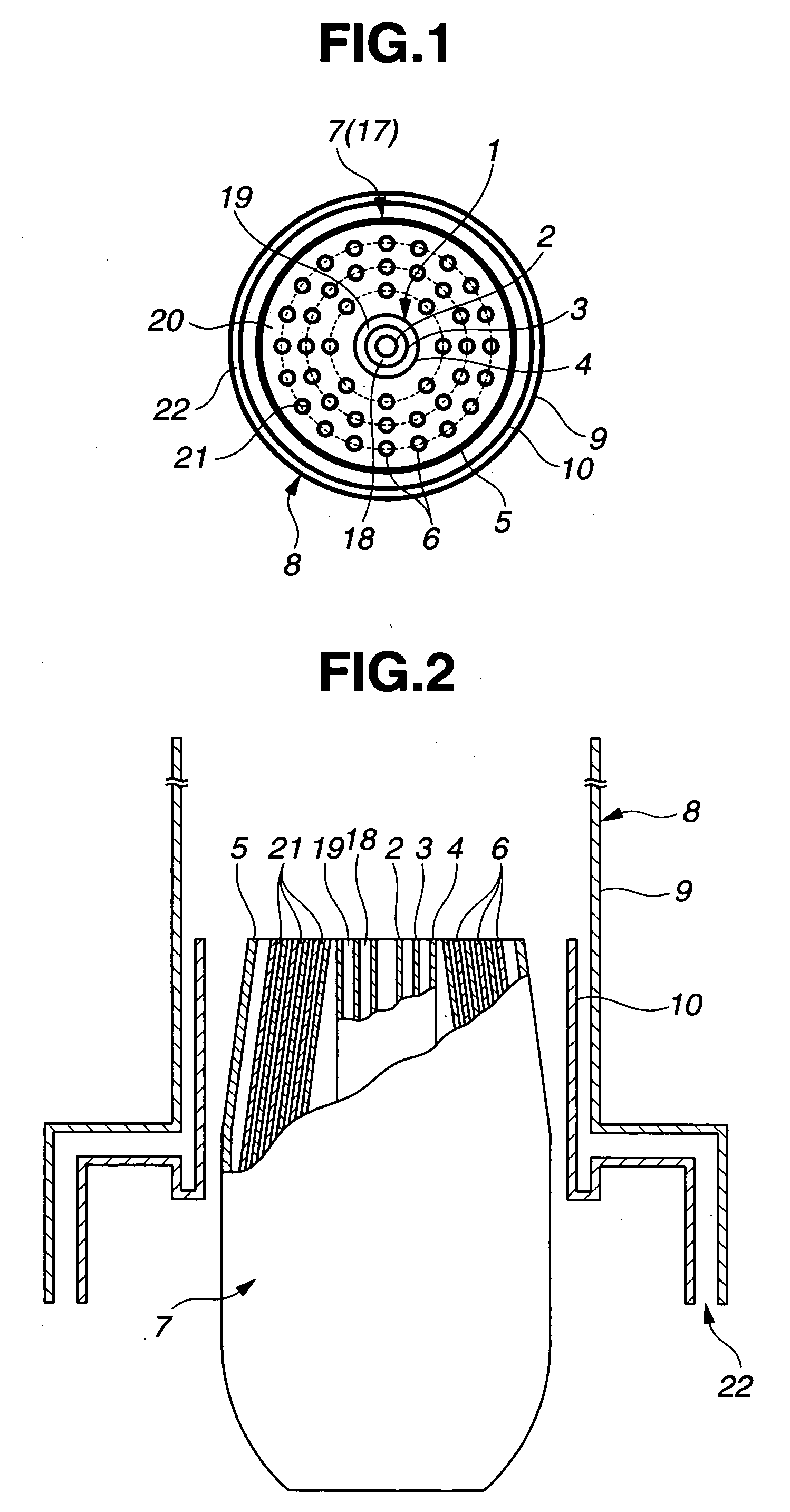

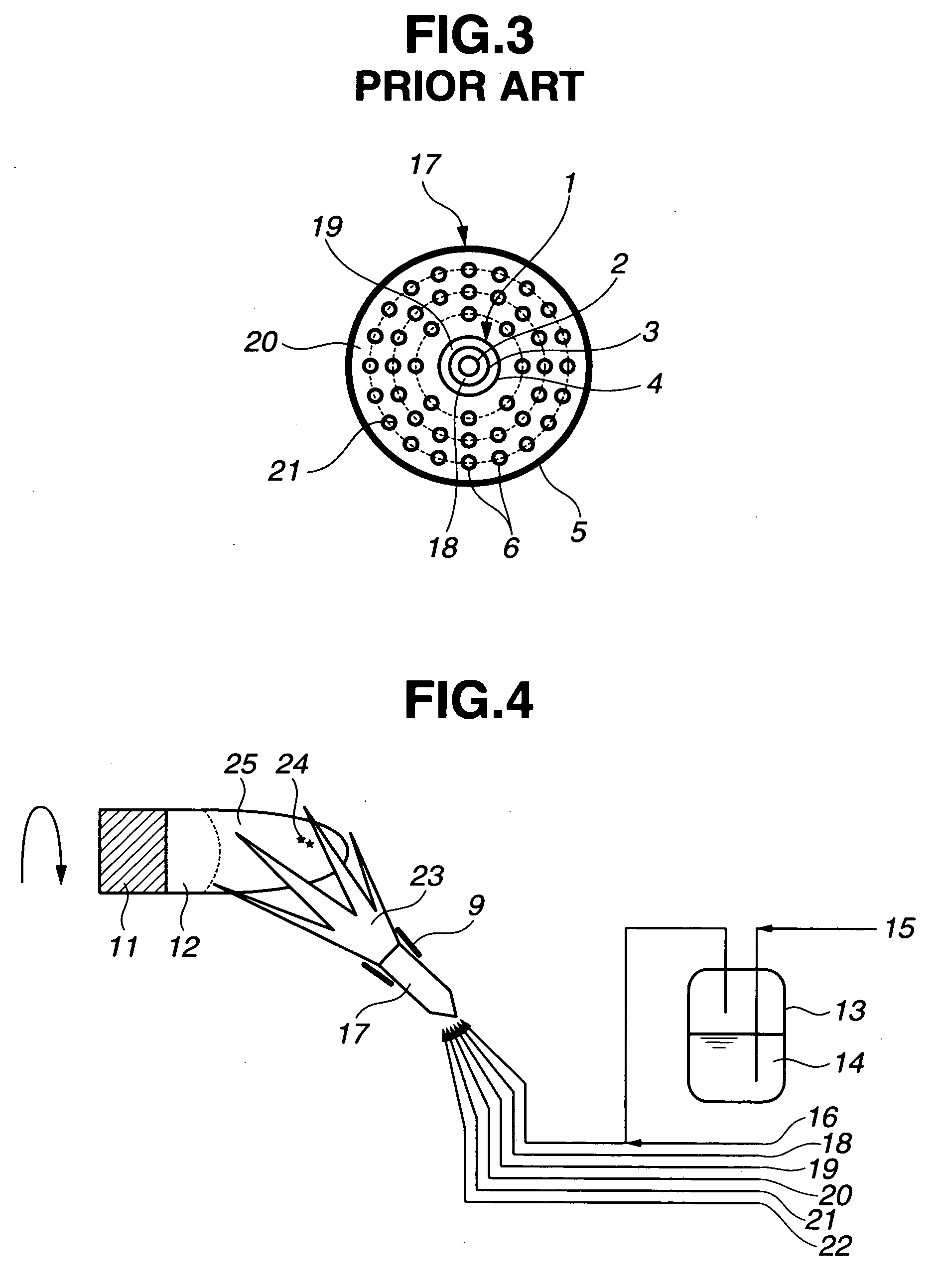

A burner for use in the manufacture of synthetic quartz glass is provided, which comprises a main burner (7) comprising a multi-tube assembly (1) including a center tube (2) for feeding a silica-forming compound, a first enclosure tube (3) surrounding the center tube for feeding a combustion-supporting gas, and a second enclosure tube (4) surrounding the first enclosure tube for feeding a combustible gas; a tubular shell (5) surrounding the multi-tube assembly for feeding a combustible gas; and a plurality of nozzles (6) disposed within the tubular shell for feeding a combustion-supporting gas. A double-tube assembly (8) is disposed so as to surround the forward opening of the main burner (7) for feeding a combustion-supporting gas. Synthetic quartz glass ingots having high optical homogeneity are produced.

Description

CROSS-REFERENCE TO RELATED APPLICATION [0001] This non-provisional application claims priority under 35 U.S.C. §119(a) on Patent Application No. 2003-406982 filed in Japan on Dec. 5, 2003, the entire contents of which are hereby incorporated by reference. BACKGROUND OF THE INVENTION [0002] 1. Technical Field [0003] This invention relates to a burner for use in the manufacture of synthetic quartz glass ingots useful as the stock material for excimer laser synthetic quartz glass optical members and large-diameter synthetic quartz glass ingots useful as the stock material for liquid crystal-related large-size photomask substrates. More particularly, it relates to a burner for use in the manufacture of synthetic quartz glass ingots having optical-grade high homogeneity and a minimal change of light transmittance and useful as optical members such as lenses, prisms, mirrors, windows and photomask substrates in excimer laser systems, especially ArF excimer laser systems. The invention als...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More IPC IPC(8): C03B19/14C03B37/014F23D14/22F23D14/32

CPCC03B19/1423C03B2201/23C03B2207/06C03B2207/08C03B2207/12C03B2207/14Y02E20/344C03B2207/36C03B2207/40F23D14/22F23D14/32F23L2900/07002C03B2207/20

Inventor OTSUKA, HISATOSHISHIROTA, KAZUO

Owner SHIN ETSU CHEM CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com