Method of forming a lead

a lead and lead-forming technology, applied in the field of lead, can solve the problems of least undesirable variance in lead diameter, too rigid and even brittle regions, etc., and achieve the effect of reducing energy consumption and low resistance during system operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] Various embodiments, including preferred embodiments, will now be described in detail below with reference to the drawings:

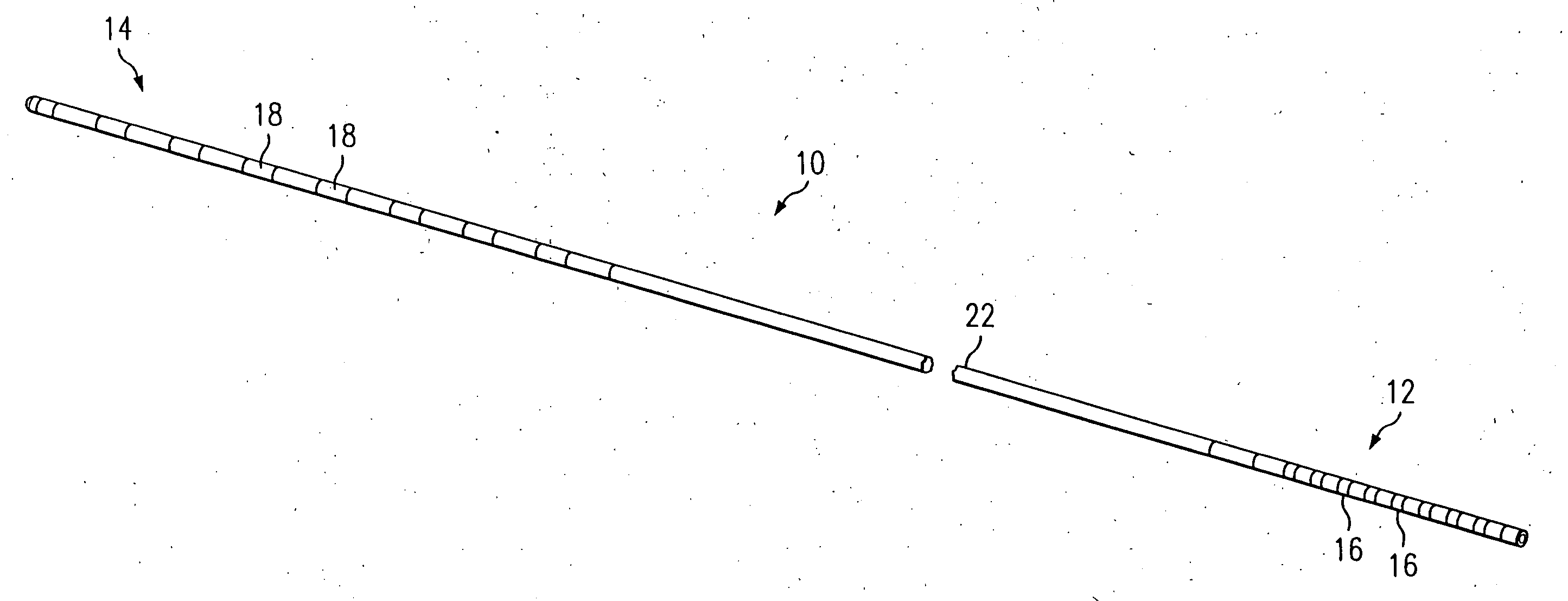

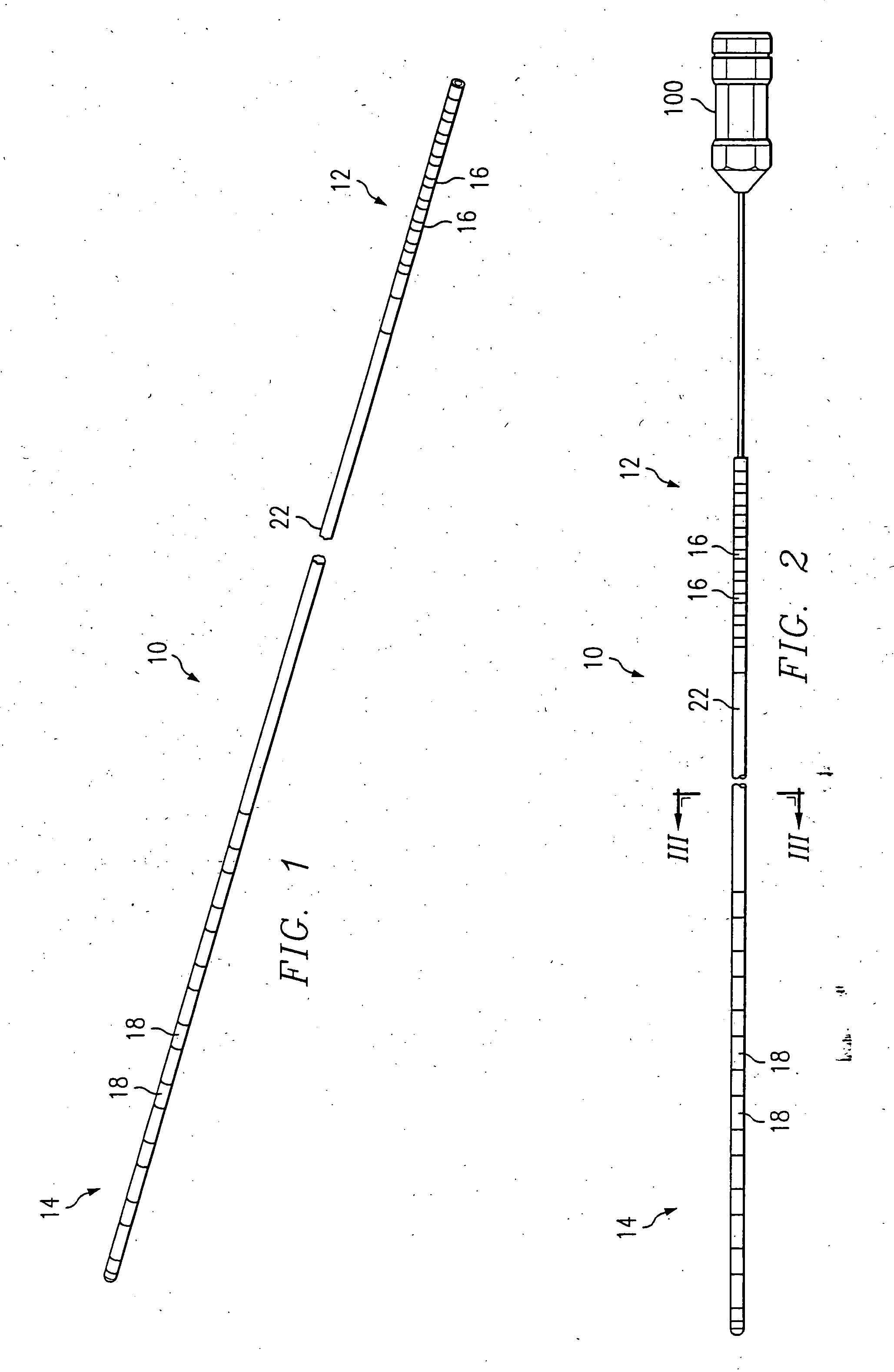

[0031]FIG. 1 illustrates a preferred embodiment of multi-electrode lead 10. While the leads illustrated and generally discussed here have eight electrodes, lead 10 of the present invention may be constructed having any number of electrodes (i.e., one or more):

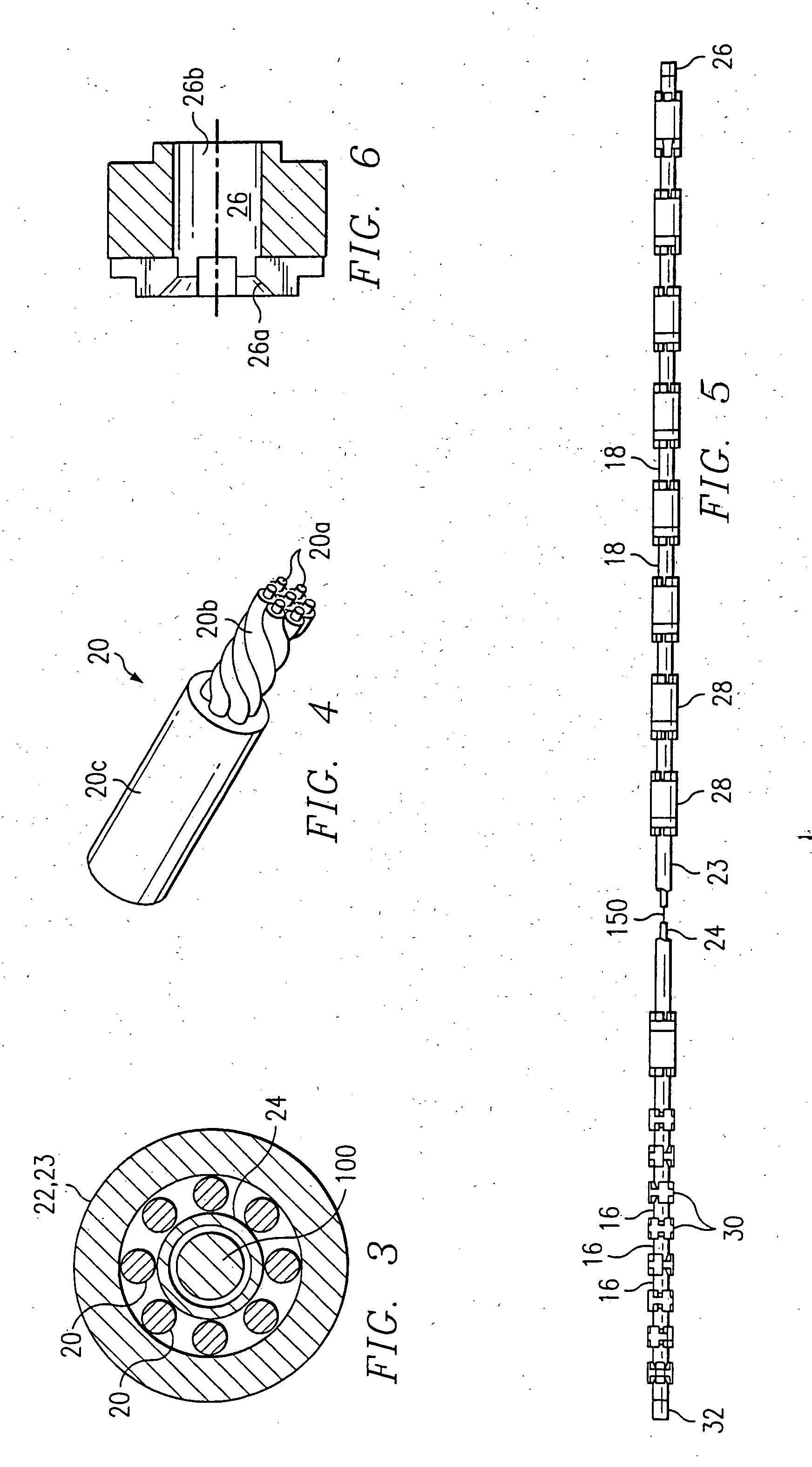

[0032] Lead 10 includes a proximal end 12 and a distal end 14. The proximal end 12 includes a plurality of electrically conductive terminals 16, and the distal end 14 includes a plurality of electrically conductive electrodes 18. While typically each terminal 16 is electrically connected to a single electrode 18 via a conductor 20 (FIG. 3), a terminal 16 can be connected to two or more electrodes 18.

[0033] Terminals 16 and electrodes 18 are preferably formed of a non-corrosive, highly conductive material. Examples of such material include stainless steel, MP35N, platinum, and platinum alloys. In a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| resistance | aaaaa | aaaaa |

| outer diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com