CMP process using slurry containing abrasive of low concentration

a technology of abrasives and slurry, which is applied in the direction of grinding machine components, manufacturing tools, lapping machines, etc., can solve the problems of wasting slurry, affecting and 3% of the slurry used in the cmp process, so as to improve the uniformity of the cmp process and ensure the yield and reliability of the devi

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The present invention will be described in detail.

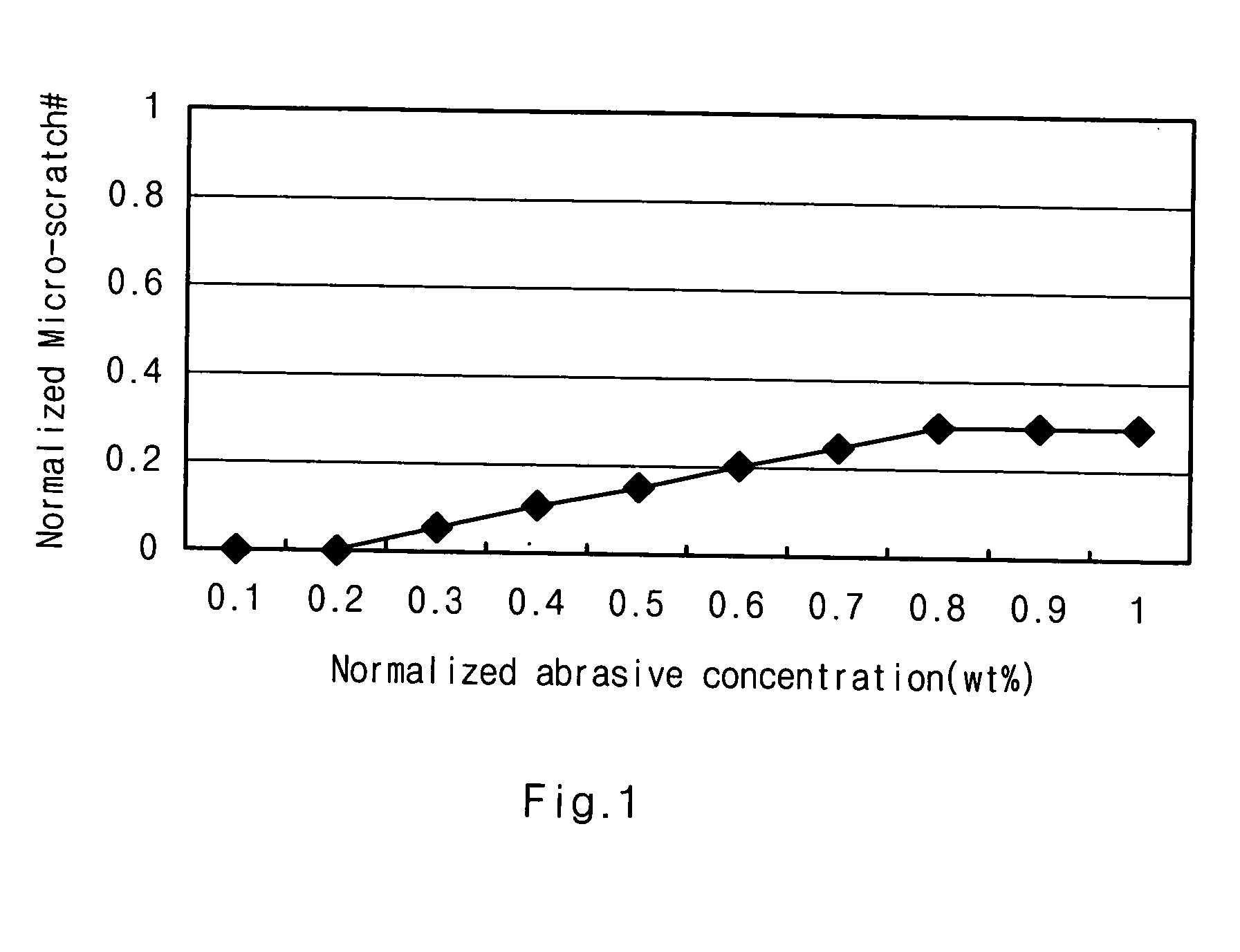

[0017] In the above-described method, the concentration of the abrasive included in the CMP slurry ranges from 0.01 to 0.1 wt %.

[0018] If the concentration of the abrasive is less than 0.01 wt %, the content of the abrasive is too low to achieve the mechanical polishing effect. If the concentration of the abrasive is more than 0.1 wt %, the planarization ability is degraded, and micro-scratch is generated according to increase in concentration of polishing particles in the slurry. Accordingly, a slurry containing an abrasive having a concentration ranging from 0.01 to 0.1 wt % is preferably used in order to maintain the proper polishing speed and minimize the micro-scratch.

[0019] Preferably, the concentration of the abrasive included in the CMP slurry ranges from 0.01 to 0.09 wt %, more preferably 0.05 wt %.

[0020] The abrasive is selected from a group consisting of ceria (CeO2), silica (SiO2), manganese oxide (MnO2) and co...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pressure | aaaaa | aaaaa |

| concentration | aaaaa | aaaaa |

| time | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com