Needleless injector with shock absorbing means between ram and piston

a technology of shock absorption and injector, which is applied in the direction of medical syringes, automatic syringes, intravenous devices, etc., can solve the problems of incomplete injection and high localised stress, and achieve the effect of reducing the initial transfer force and reducing the initial pressure increase on the liquid

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

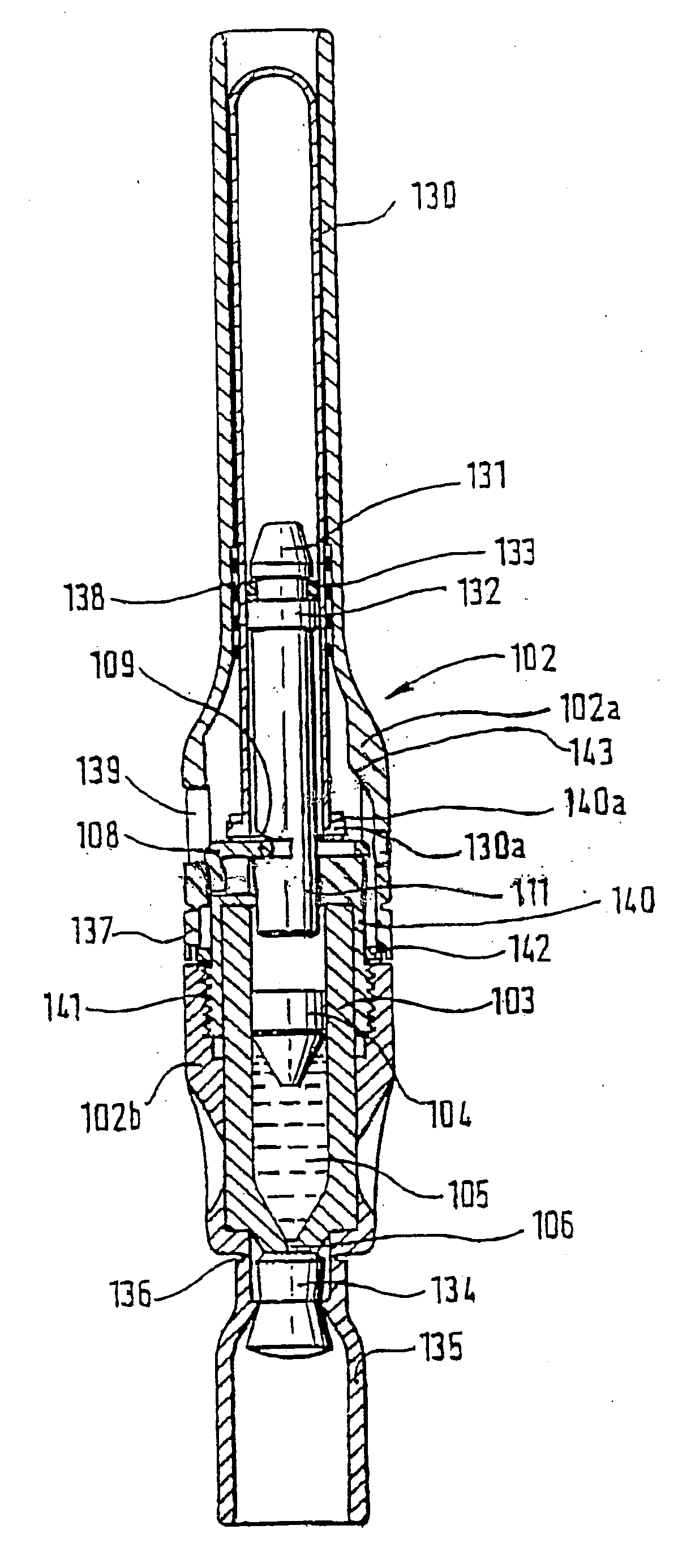

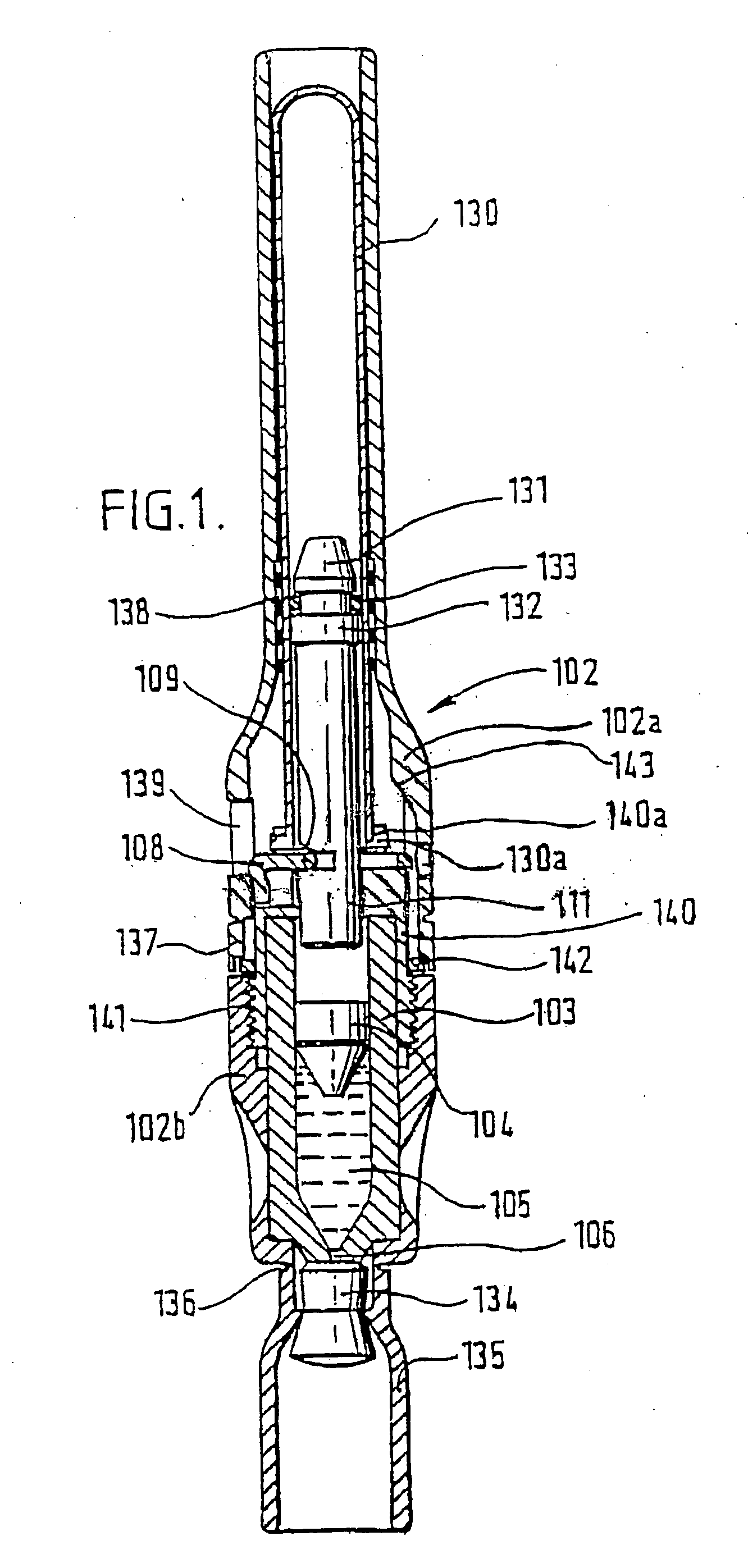

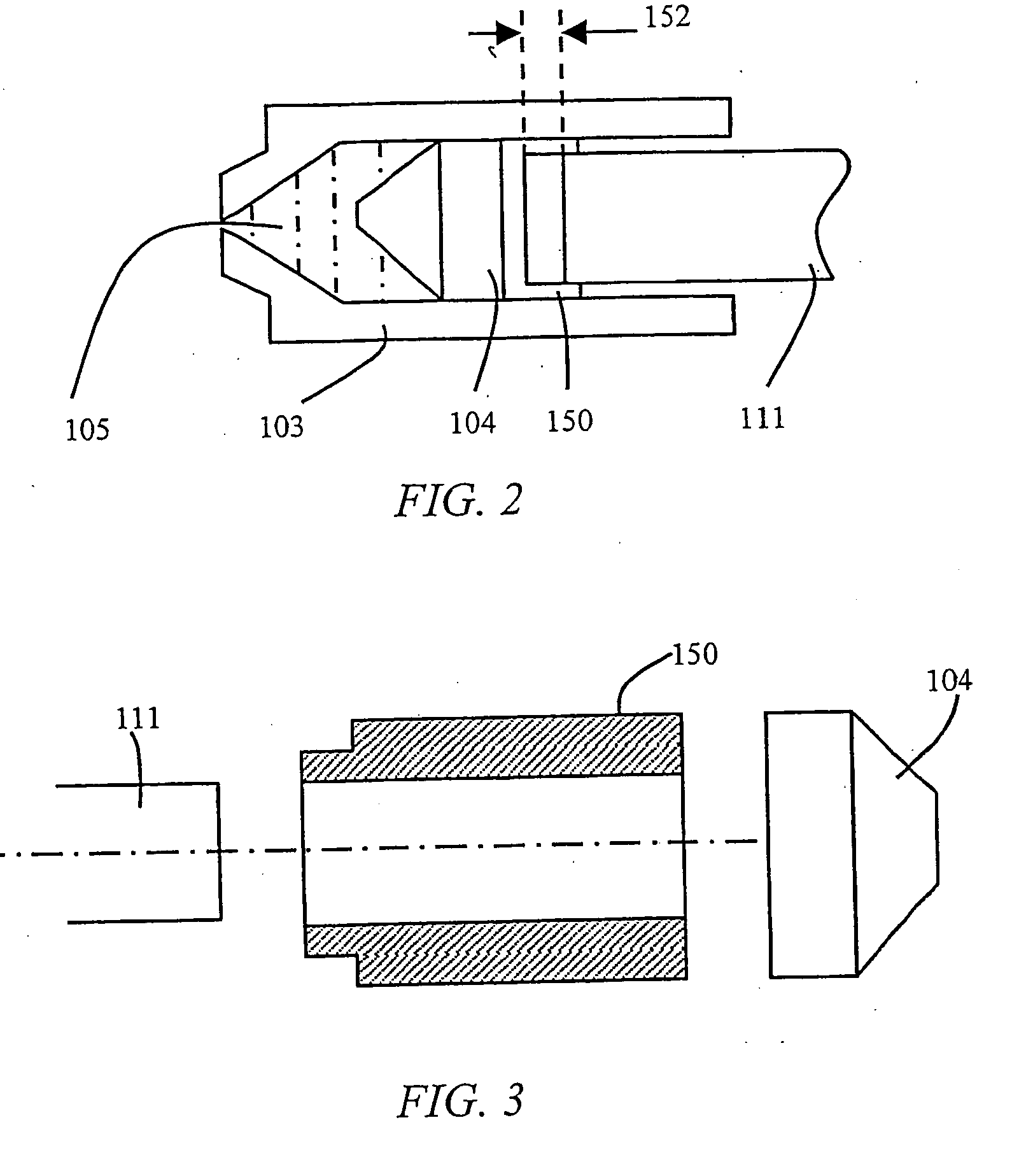

[0035]FIG. 1 shows a known needleless injector, comprising a syringe body in the form of a cartridge 103 having an opening 106 at one end. A piston 104 is housed within the cartridge 103 for urging a liquid 105 within the cartridge through the opening 106. A ram 111 is provided for driving the piston, and an arrangement is provided for applying a force to the ram 111.

[0036] The are numerous possible ways of applying force to the ram. In the example shown, the injection force is provided by a compressed gas spring. This is in the form of a cylinder 130 which is closed at its upper end and which contains gas, typically air, under a pressure which is typically in the range 5.5 MPa (800 psi) to 22 MPa (3000 psi). The cylinder houses the ram 111. The end of the ram 111 has a frustoconical portion 131 and a flange 132 between which is situated an O-ring seal 133. Prior to use, the ram 111 is held in the illustrated position by a latch 108 engaging in a groove in the ram, the upper surfac...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com