Shoe with an articulated spring-loaded outsole

a technology of spring-loaded outsoles and shoes, which is applied in the field of shoes, can solve the problems of not being able to adjust the spring/damping properties with such an arrangemen

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

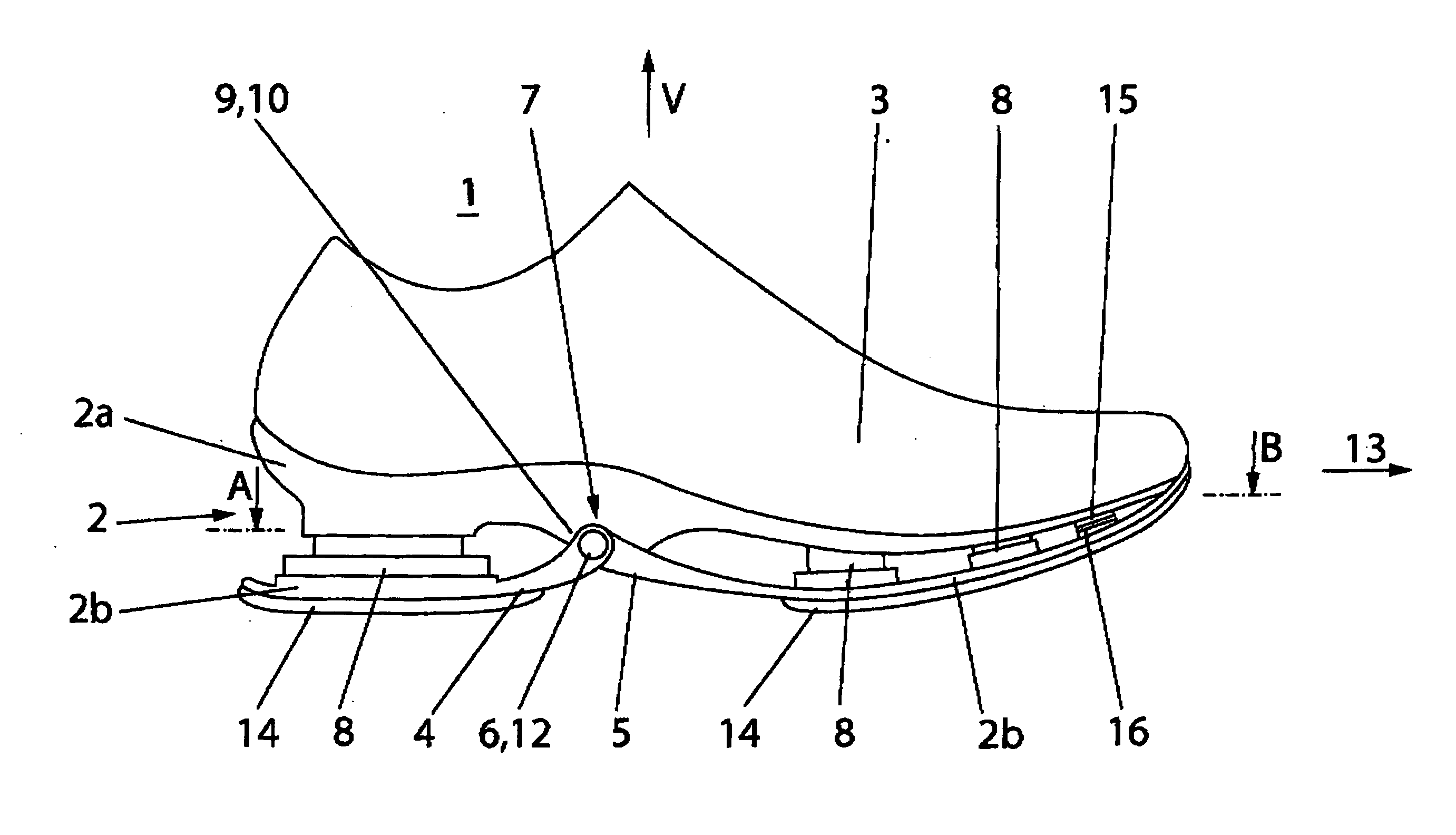

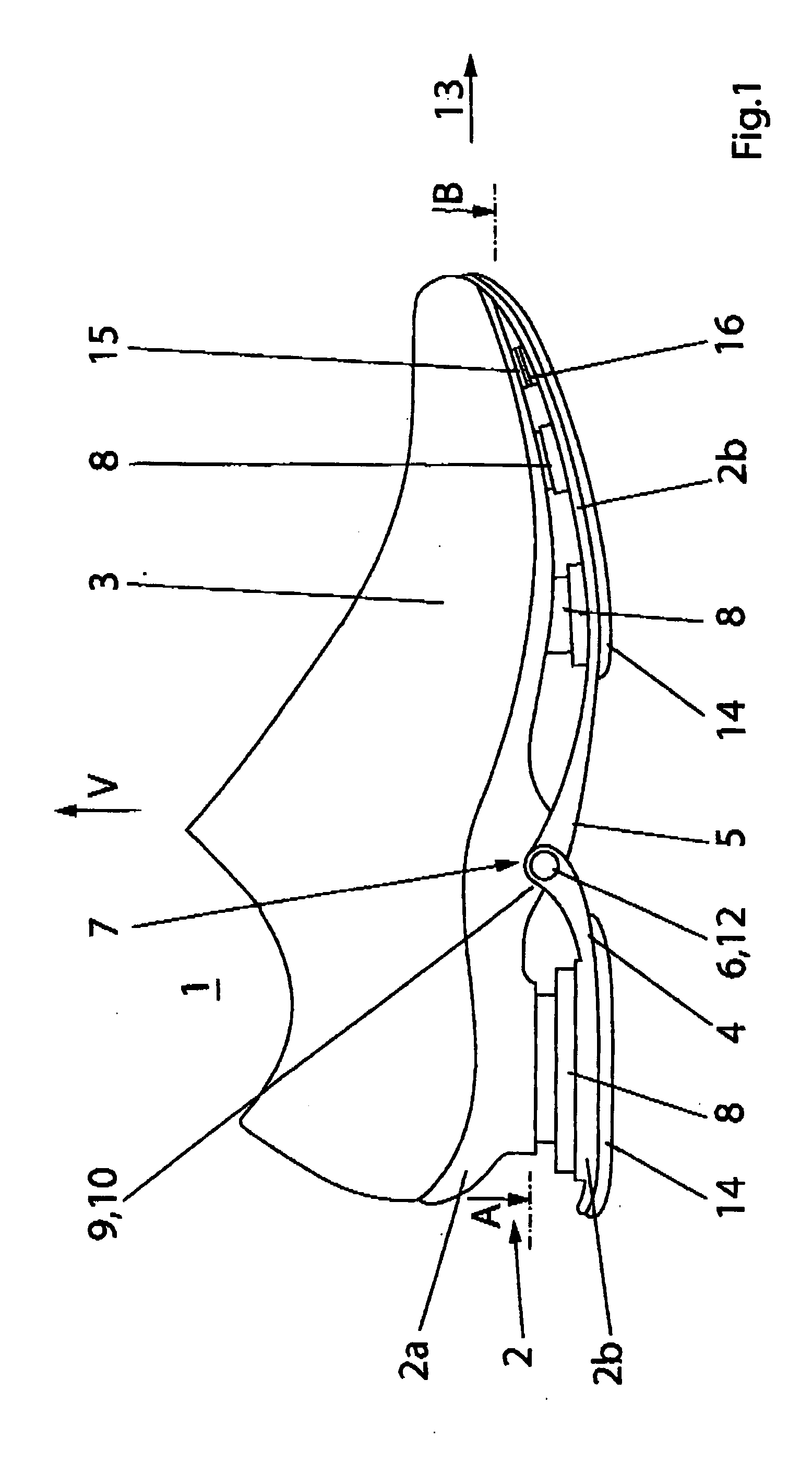

[0035]FIG. 1 shows a shoe 1 of the type which is used as a running shoe and which, as is conventional, has an upper 3. Underneath (for orientation, the direction of the upward vertical arrow V is shown) upper 3 is a midsole designated 2 as whole. Affixed to the underside of the midsole 2 is the outer sole 14, which is in the form of a rubber sole.

[0036] The midsole 2 is foamless, i.e., it does not have any foamed material, especially any foamed plastic materials, in contrast to a typical midsole which is formed entirely or to a substantial extent of foamed plastic material.

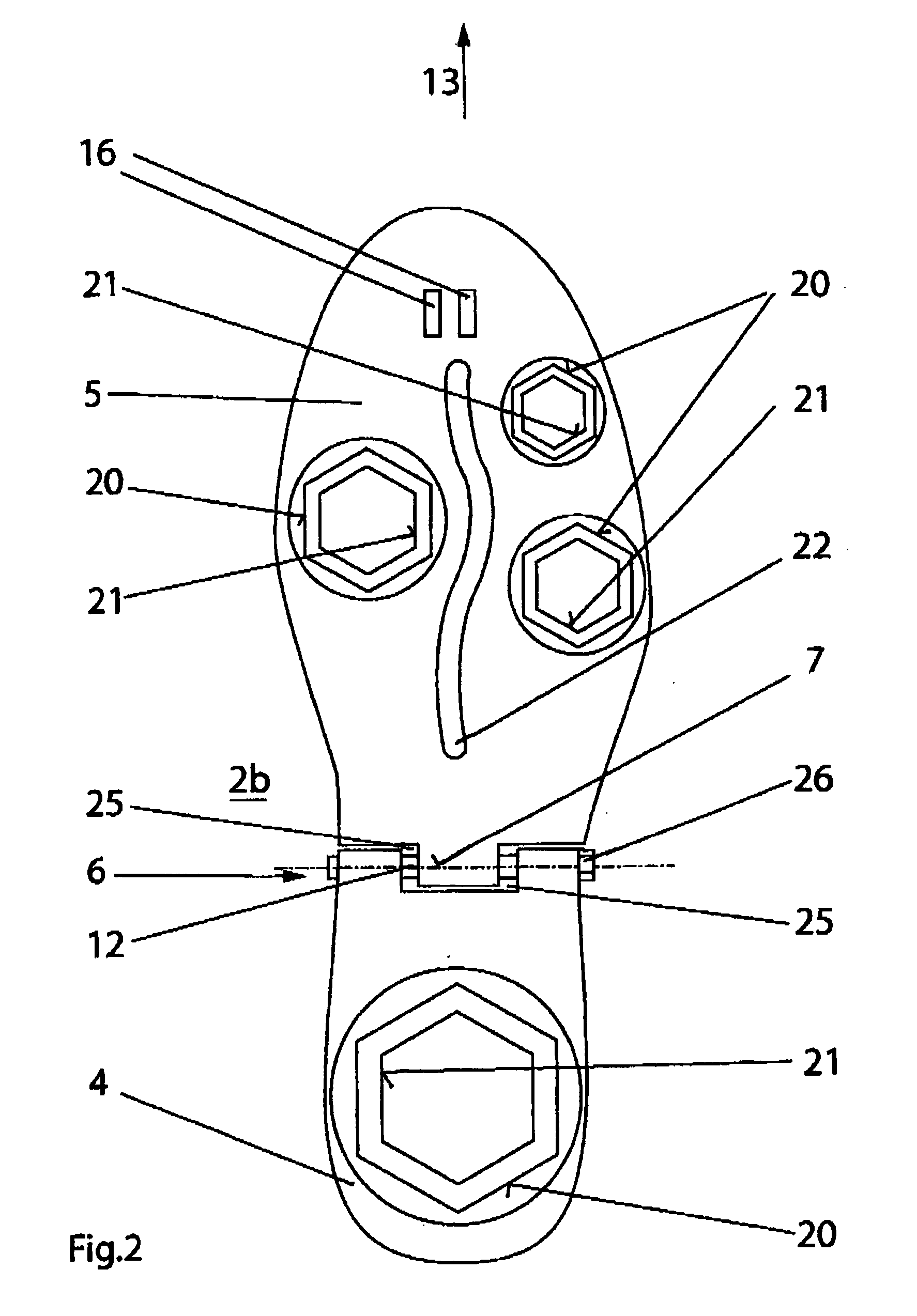

[0037] The midsole of the present invention is comprised of a base body 2a which is permanently connected to the upper 3, and of a bottom plate 2b which is located below the base body 2a, to the underside of which the outer sole 14 is attached. The bottom plate 2b, here, is formed of two parts 4, 5, specifically, a part 4 in the form of a rear foot bottom plate and a part 5 in the form of a forefoot bottom plate...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com