Vertical nanotube semiconductor device structures and methods of forming the same

a technology of vertical fet devices and semiconductor devices, which is applied in the field of vertical fet device structures, can solve the problems of large variation in current flowing from the source to the drain, and the method of forming such horizontal fet device structures is incompatible with mass production techniques

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

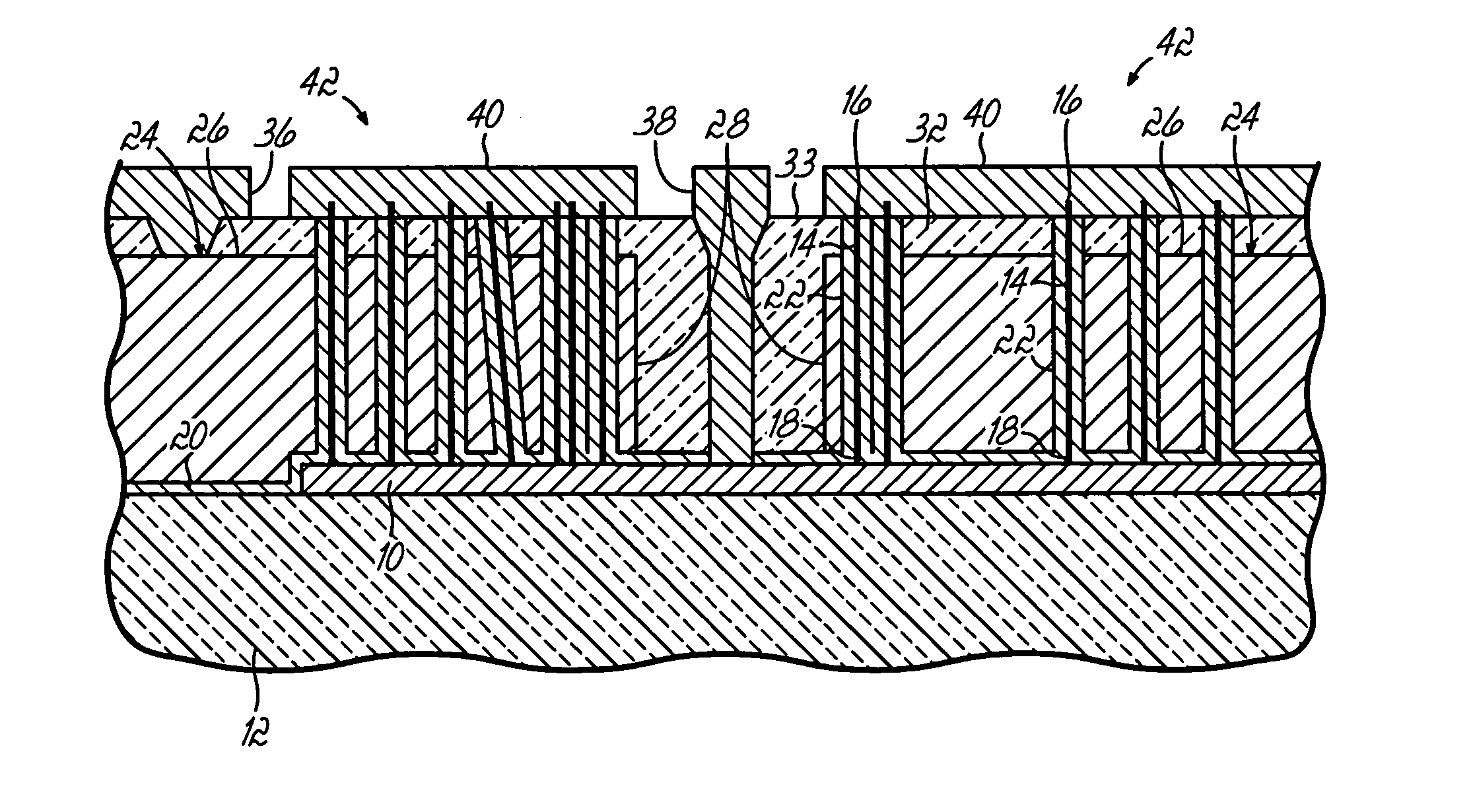

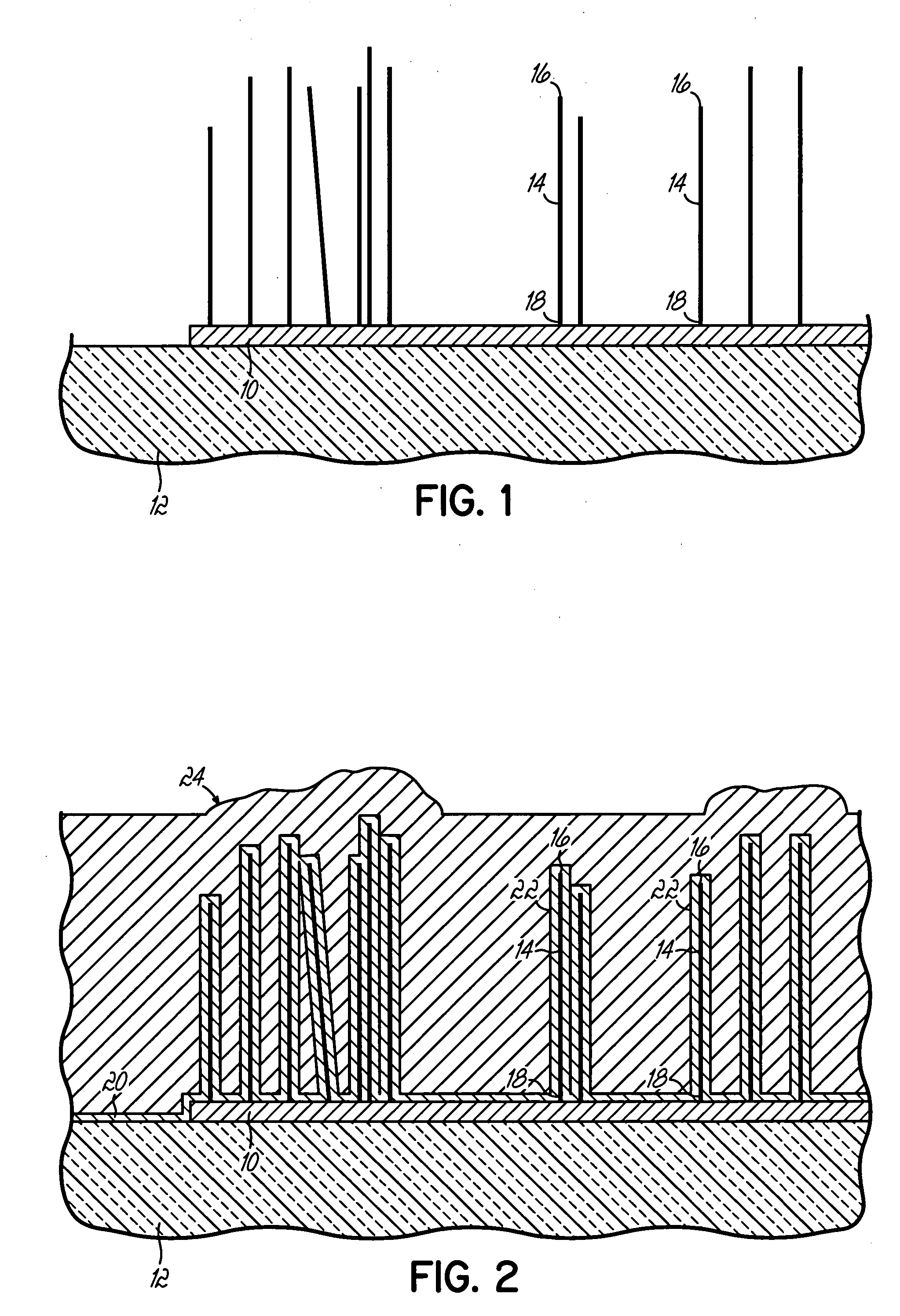

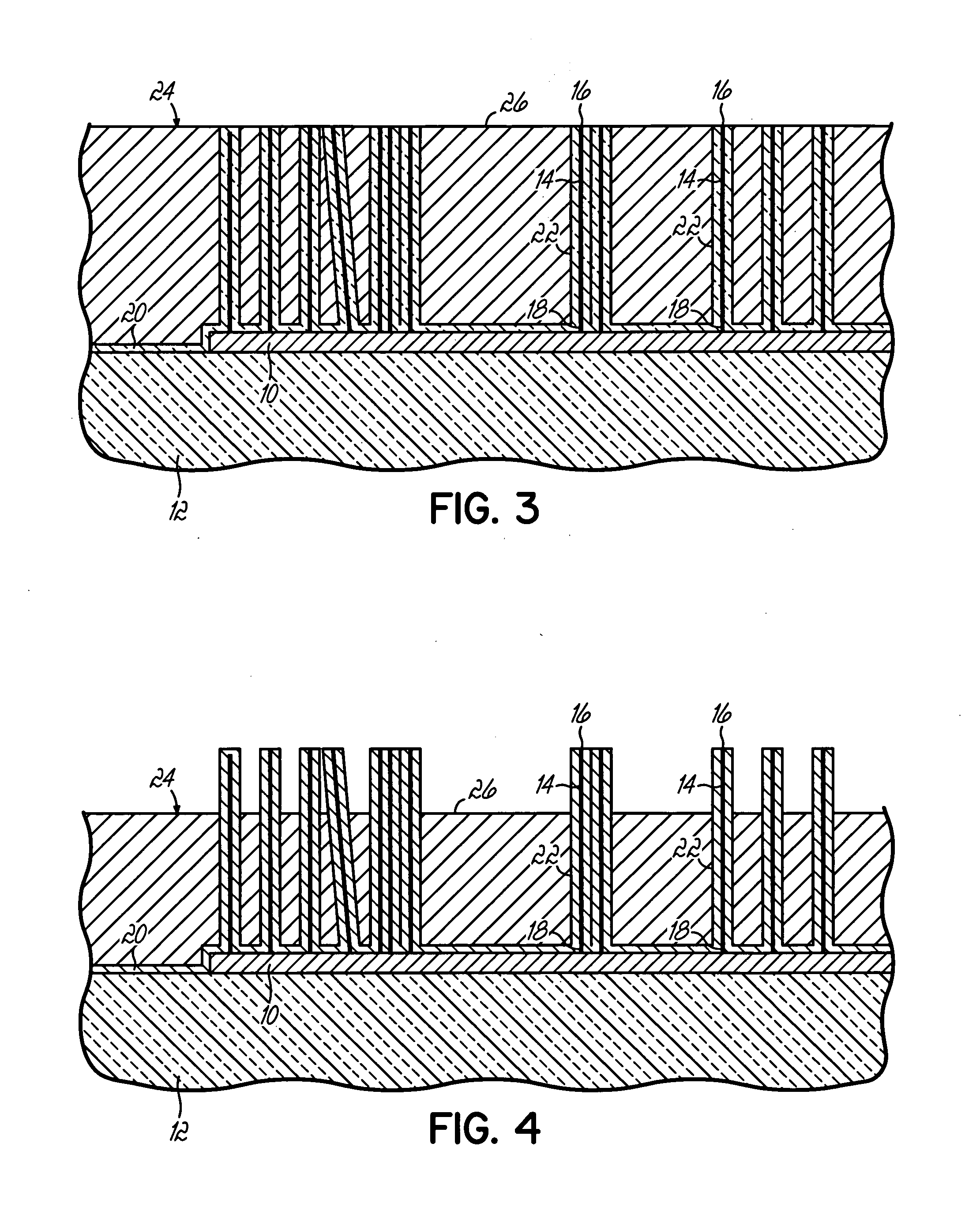

[0022] The invention is directed to vertical field effect transistors (FET's) that utilize carbon nanotubes as a semiconducting material for the channel region providing a selective conduction path between a source and a drain when a voltage is applied to an electrostatically-coupled gate electrode. In accordance with the principles of the invention, the length of the channel region between the source and drain is defined by the thickness of the gate electrode, which is substantially equal to the nanotube length, and is not dependent upon a resolution-limited lithographic process. The carbon nanotubes do not have to be individually manipulated for placement between a source and a drain nor does device fabrication depend upon coincidental alignment with the source and drain of one or more nanotubes randomly dispersed on the device surface.

[0023] With reference to FIG. 1, a catalyst pad 10 of a catalytic material suitable for supporting the growth of carbon nanotubes 14 is formed as ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| semiconducting | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com