Roller with salient members

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

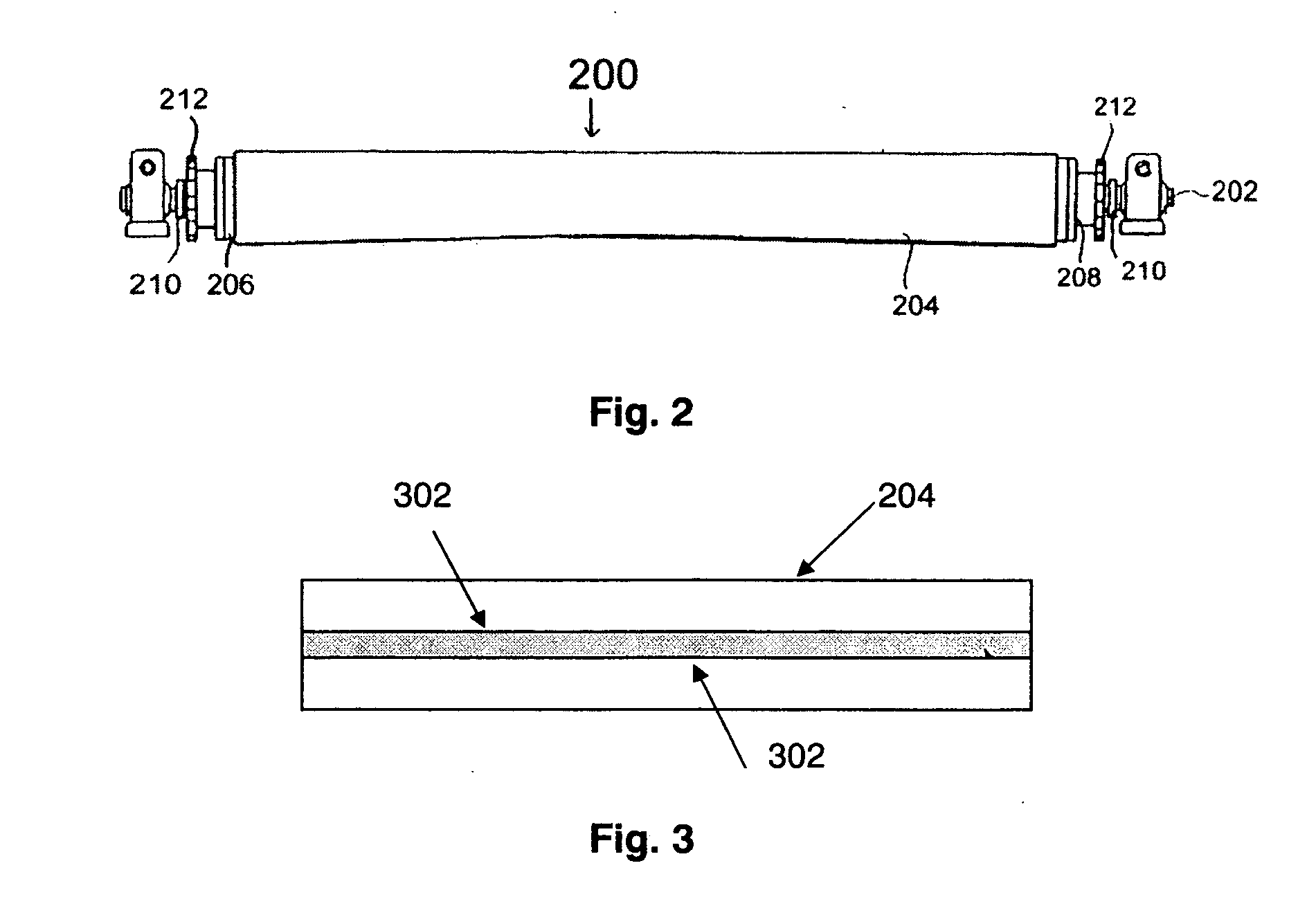

[0027]FIG. 2 is a simplified illustration of roll 200, which includes a roller shaft 202 and a sheet roller 204. It should be understood that the construction of roll 200 can be accomplished using any conventional parts and manufacturing techniques.

[0028] In one exemplary embodiment with no intent to limit the invention, as FIG. 2 shows, sheet roller 204 can be rotatably mounted on a plurality of casings housing bearings on roller shaft 202. Sheet roller 204 may be configured to have many shapes, for example, sheet roller 204 can have an outer circumference that is constant or, which gradually increases or decreases progressively in an axial direction from its central part toward its opposite end parts.

[0029] In this embodiment, end flanges 206 can be fitted in the end parts of sheet roller 204. Set flanges 208 can be mounted on the external sides of the end flanges. Set sleeves 210 can be fitted onto roller shaft 202. Gears 212 may be used to transmit a drive force for rotation o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com