Stackable tray

a technology of trays and trays, applied in the field of trays, can solve the problems of damage to products, inability to address the crosswise nesting of trays, and space required to store or transport the largest possible quantity of articles or products without damag

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

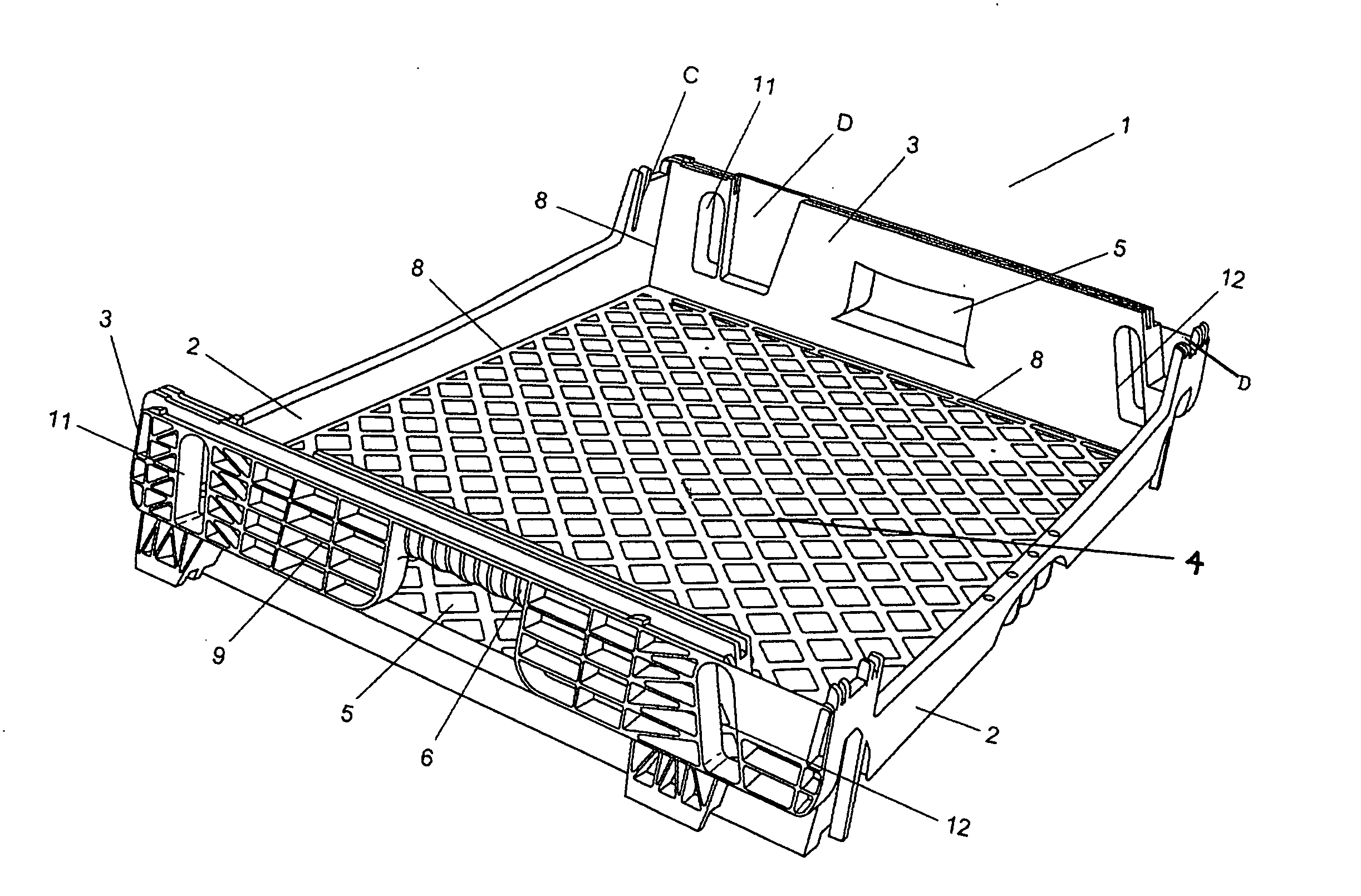

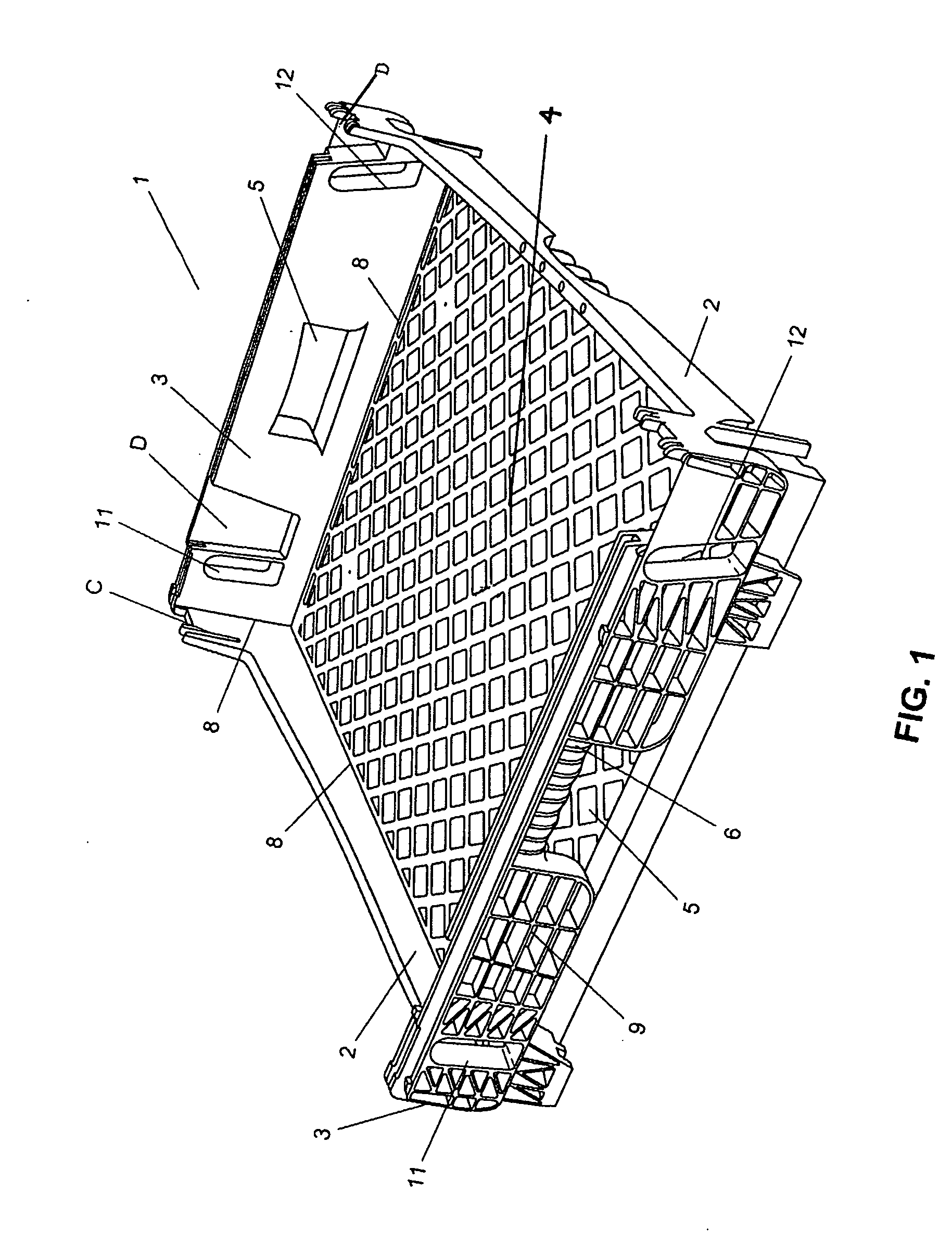

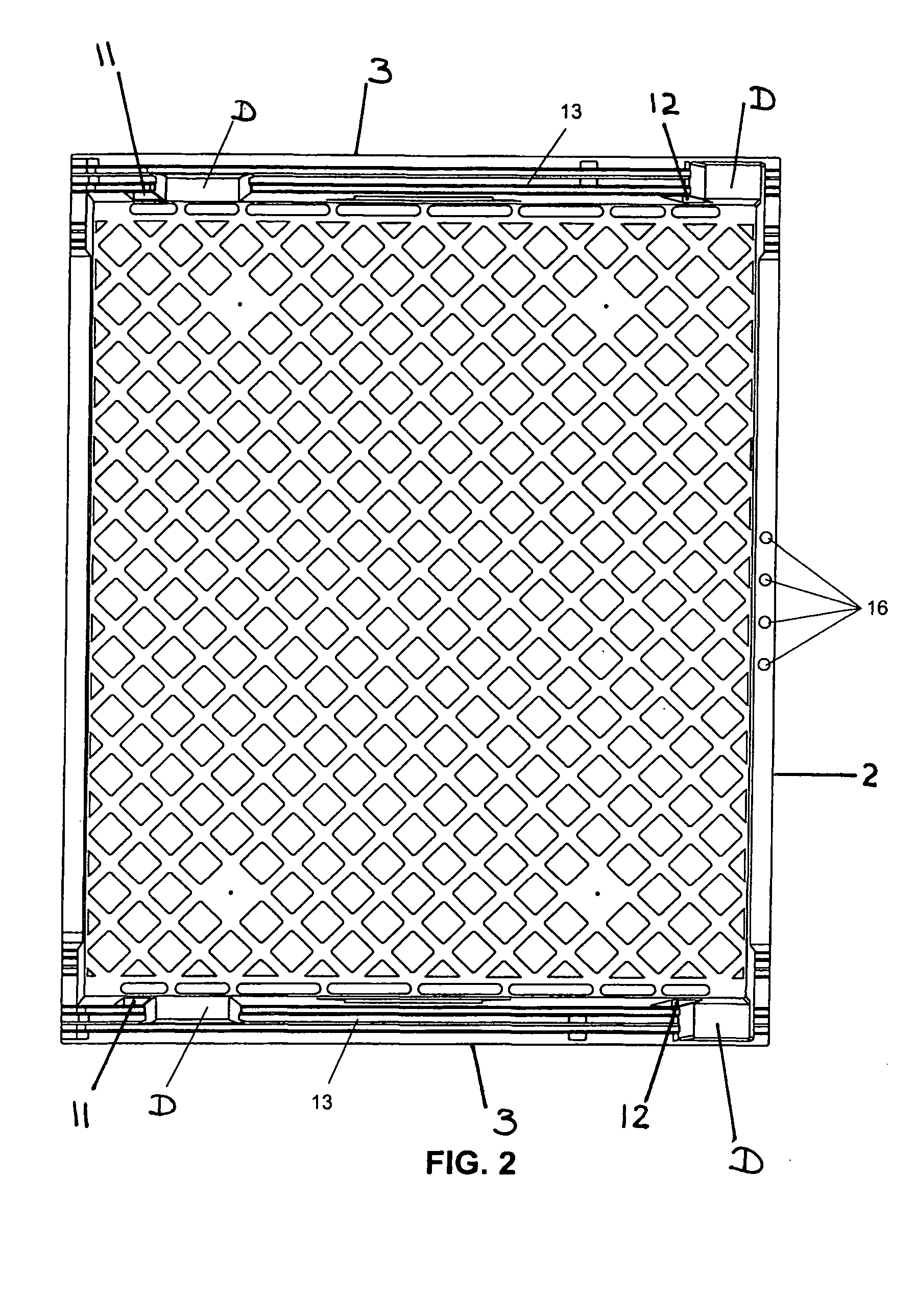

[0032] With reference now to the figures, FIG. 1 shows how the receptacle, container, or tray (1) is designed in a manner similar to a box, including two sides of reduced height (2), which have, on the inside of two of their corners, slots or recesses (C) for receiving or mating with a vertical structural element or rod, and two sides of greater height (3), and a floor element (4) that may have various different design patterns, or no patterns, or which may be perforated or uniformly solid, as desired, although it is preferably perforated, so as to allow ventilation when the products consist, for example, of perishable items, bread, etc. The sides of greater height have sliding elements in order to allow the sliding of an upper tray to be stacked, recesses, and coupling elements (D) (two on each side), in which feet are seated so as to allow an upper tray to be nested or stowed (see FIGS. 8, 9, and 11), thereby providing spaces of different heights, depending on the required orienta...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com