Electrochemical fabrication methods incorporating dielectric materials and/or using dielectric substrates

a technology of dielectric substrates and fabrication methods, applied in the field of electrochemical fabrication, can solve the problems of destructive separation of masking materials from substrates, and achieve the effect of reducing the number of defects and avoiding the formation of defects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

first embodiment

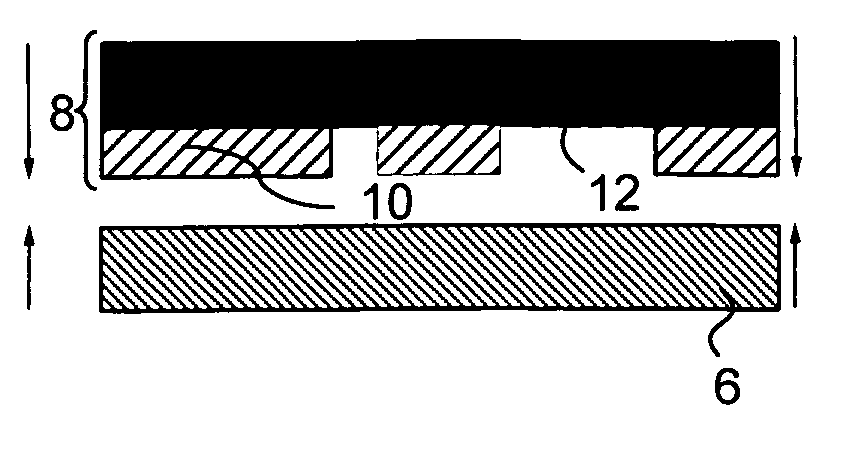

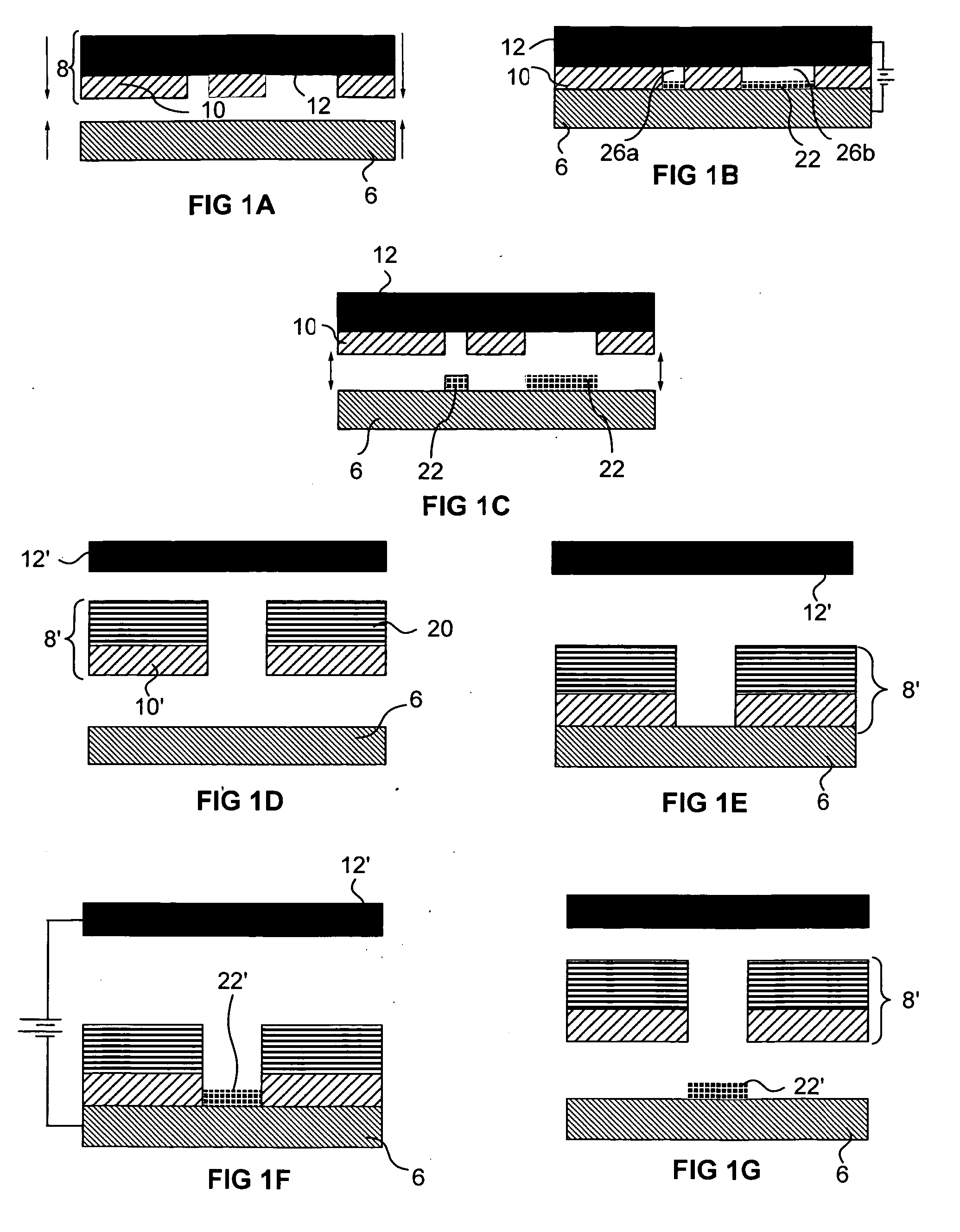

[0110]FIGS. 6A-6J provide schematic illustrations of side views of a sample structure at various stages of fabrication according to the process of the invention.

[0111]FIG. 6A shows the state of the process after a dielectric substrate 202 has been supplied. For illustrative purposes the dielectric substrate 202 is shown as resting upon and being surrounded by a conductive material 204 to which electrical contact may be made for the purposes of performing plating operations and the like.

[0112]FIG. 6B shows the state of the process after a seed layer material 206 has been blanket deposited over the surface of the dielectric substrate 202.

[0113]FIG. 6C shows the state of the process after a barrier layer or etch stop layer 208 has been blanket deposited over seed layer material 206.

[0114]FIG. 6D shows the state of the process after a sacrificial material 212 has been selectively deposited onto the barrier layer and any mask used during the selective deposition process has been remov...

second embodiment

[0134]FIGS. 7A-7J provide schematic illustrations of side views of a sample structure at various stages of fabrication according to the process of the invention.

[0135]FIG. 7A depicts the state of the process after a substrate 232 supported by conductive carrier 234 is supplied.

[0136]FIG. 7B shows the state of the process after a seed layer 236 is blanket deposited onto the surface of substrate 232.

[0137]FIG. 7C shows the state of the process after a patterned mask 210 is applied to the surface of the seed layer material located on substrate 232 and after a barrier layer material 238 has been deposited to the seed layer material in the regions of voids 244.

[0138]FIG. 7D depicts the state of the process after a sacrificial material 242 has been deposited over etch stop material 238.

[0139]FIG. 7E shows the state of the process after the masking material 210 has been removed resulting in formation of voids 250 over portions of the seed layer material where structural material is to ...

third embodiment

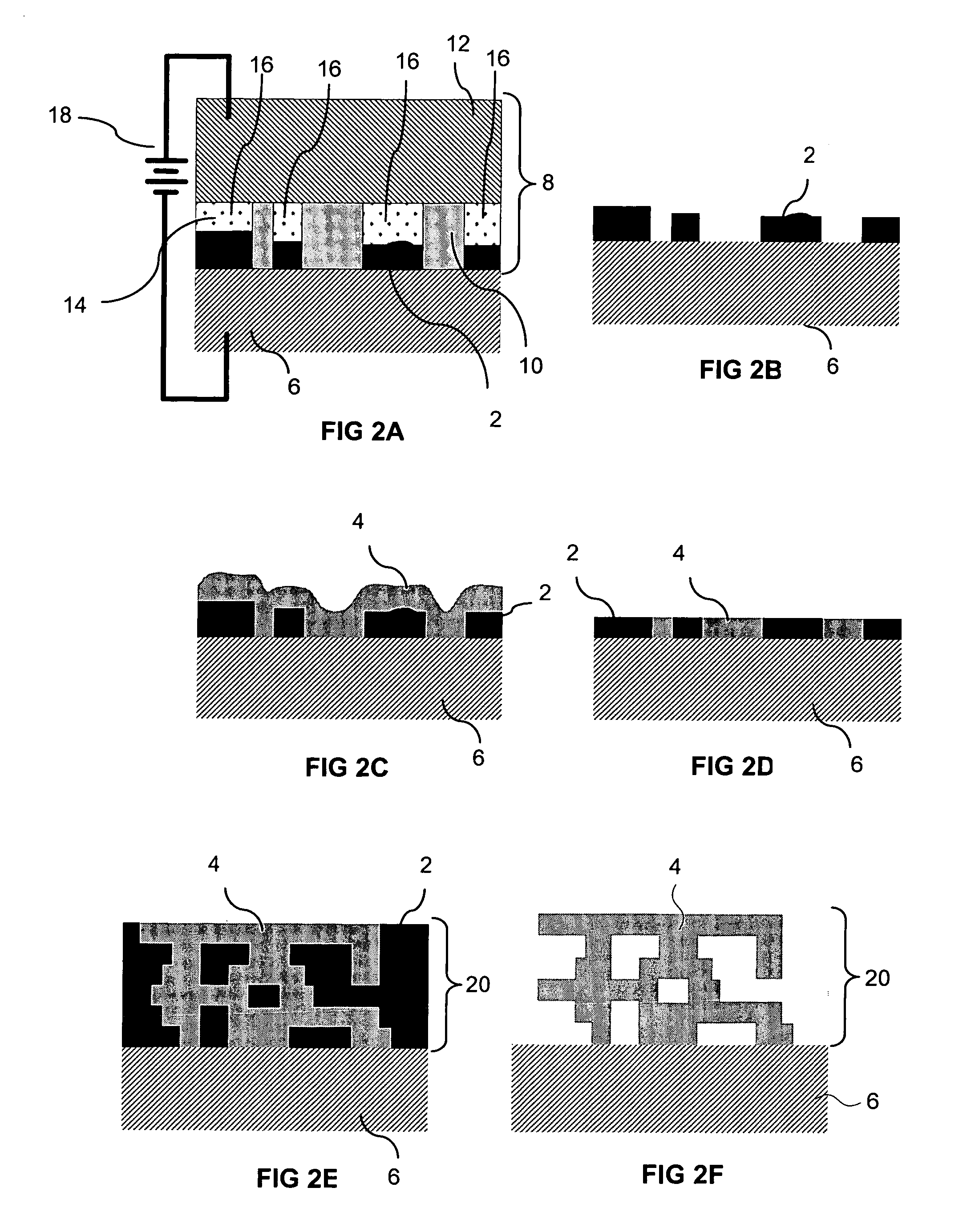

[0153]FIGS. 8A-8J provide schematic illustrations of side views of a sample structure at various stages of fabrication according to the process of the invention.

[0154]FIG. 8A depicts the state of the process after a dielectric substrate 262 and a conductive carrier 264 is supplied.

[0155]FIG. 8B depicts the state of the process after a seed layer material (e.g. a copper nickel alloy) is supplied to the surface of substrate 262.

[0156]FIG. 8C shows the state of the process after a masking material 270 is applied and patterned on the surface of seed layer material 266 and structural material 276 is deposited onto the seed layer via the openings in mask material 270.

[0157]FIG. 8D depicts the state of the process after the masking material has been removed and an etch stop material 268 has been plated over exposed regions of the seed layer as well as over the deposited structural material.

[0158]FIG. 8E shows the state of the process after a sacrificial material 272 has been blanket de...

PUM

| Property | Measurement | Unit |

|---|---|---|

| temperature | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thicknesses | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com