Door sealing assembly

a door and mirror technology, applied in the field of automobile body seals and moldings, can solve the problems of prior art sealing, difficult sealing of the vehicle body at the pillar (the roof pillar adjacent to the vehicle door), and difficulty in sealing the surface of the door glass, so as to reduce wind noise and water leakage, improve sealing performance, and be more robust

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

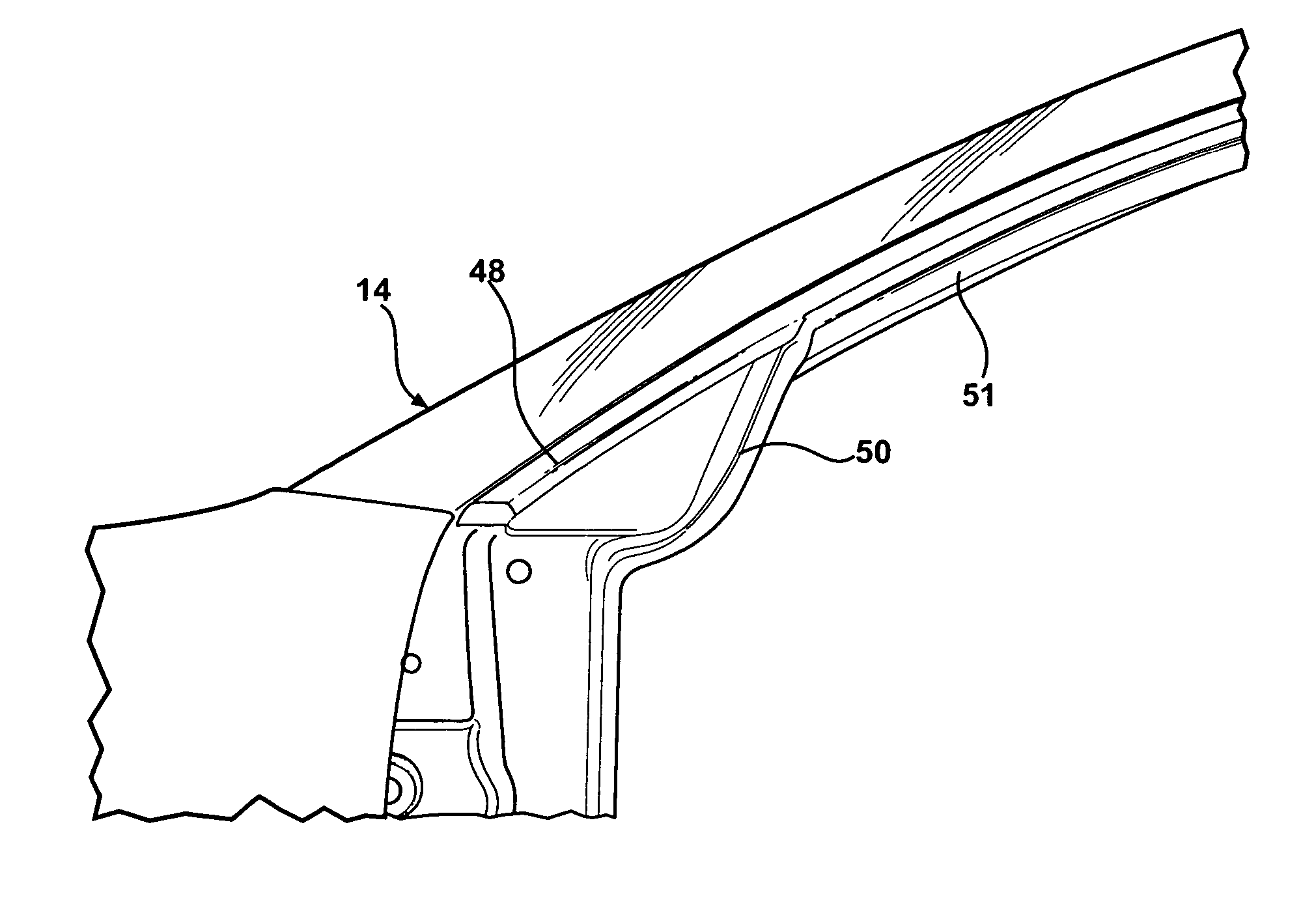

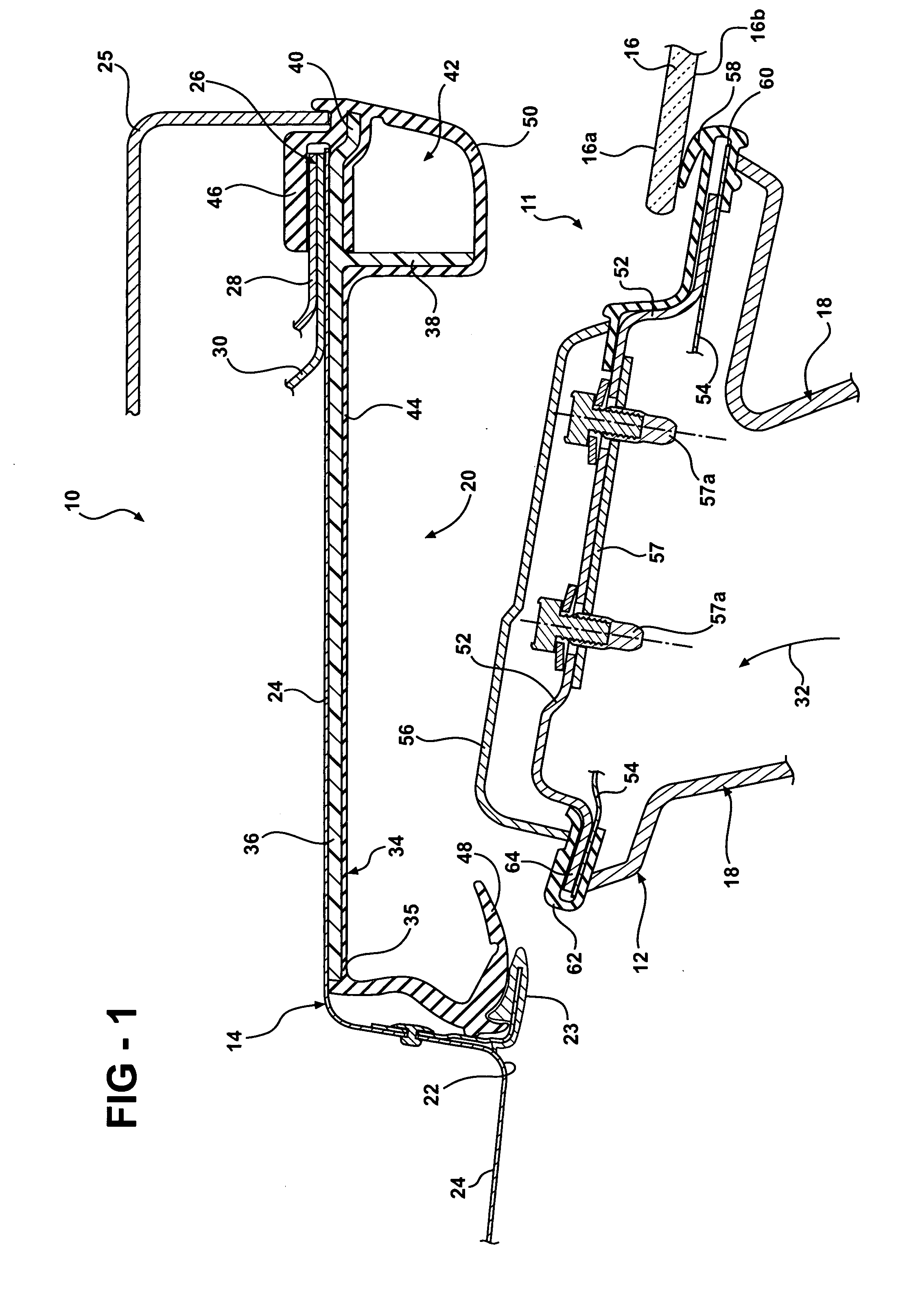

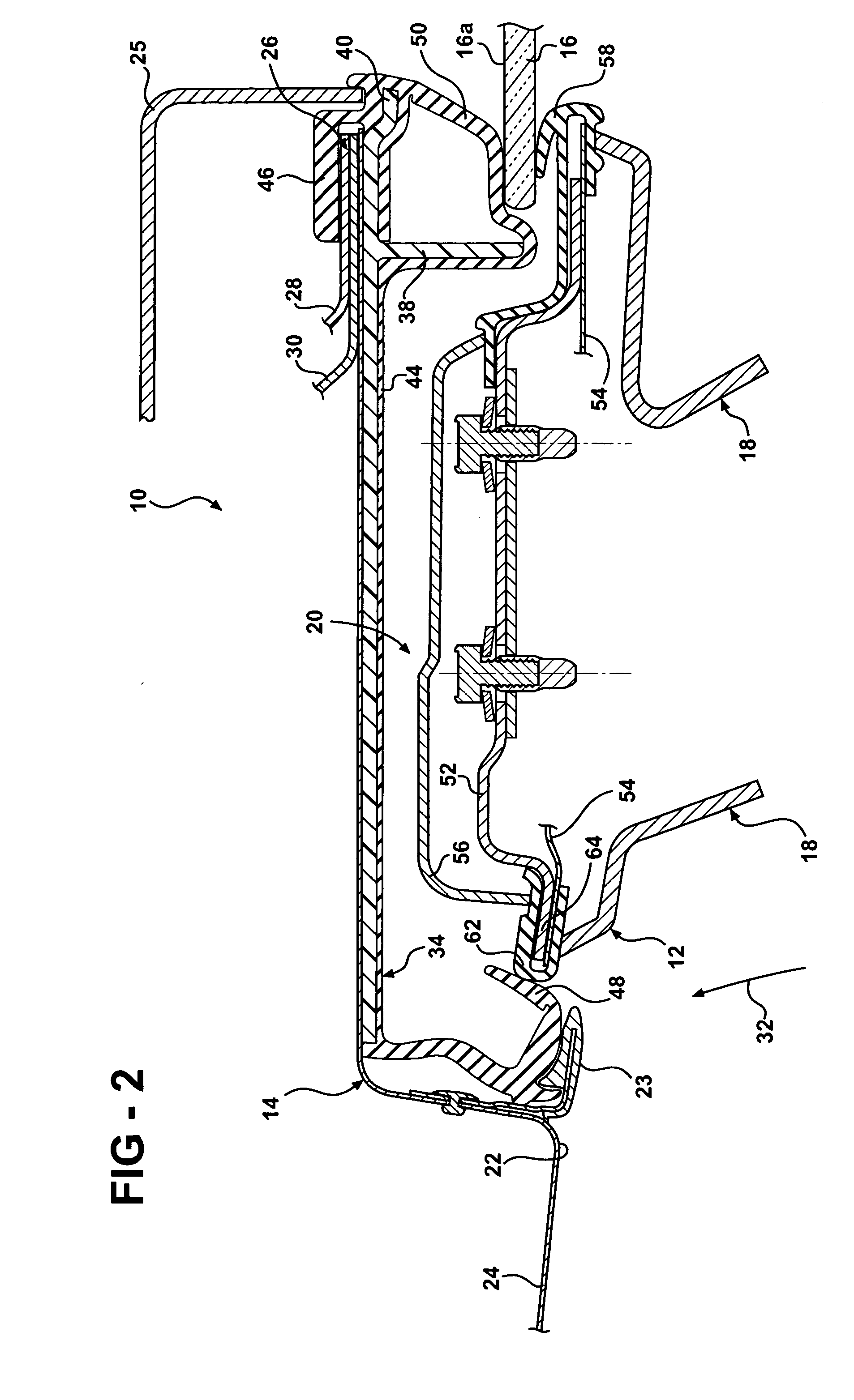

[0012] Referring now to FIGS. 1-4, a sealing assembly in accordance with the present invention is indicated generally at 10. The sealing assembly 10 is operable to seal mating surfaces of a vehicle door 12 and a body 14, such as a vehicle body. Preferably, the body 14 is a portion of the A-pillar of a vehicle body. The vehicle door 12 includes a door glass 16, which includes an inner surface 16a and an outer surface 16b, attached thereto. Preferably, the door glass 16 is a frameless door glass, best seen in FIG. 3. A frameless door glass, such as the door glass 16, does not include a window frame extending upwardly from the vehicle door wherein the door glass travels in a path defined by the window frame or a header. A mirror patch portion 18 extends outwardly from the vehicle door 12 adjacent a front edge of the door glass 16. Preferably, the door glass 16 is movable along a vertical path (not shown) within the vehicle door 12 by a window regulator (not shown) or the like. A side v...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com