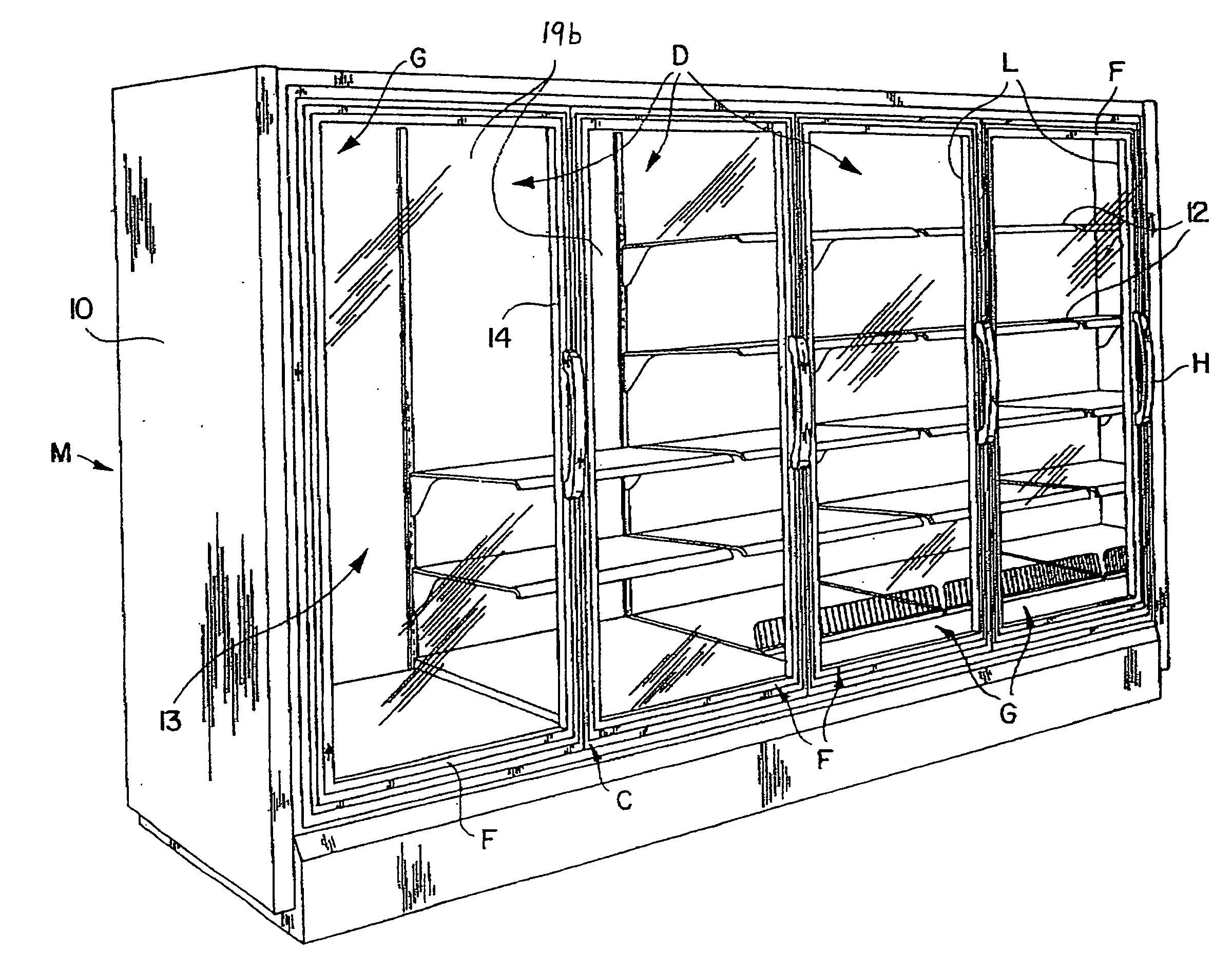

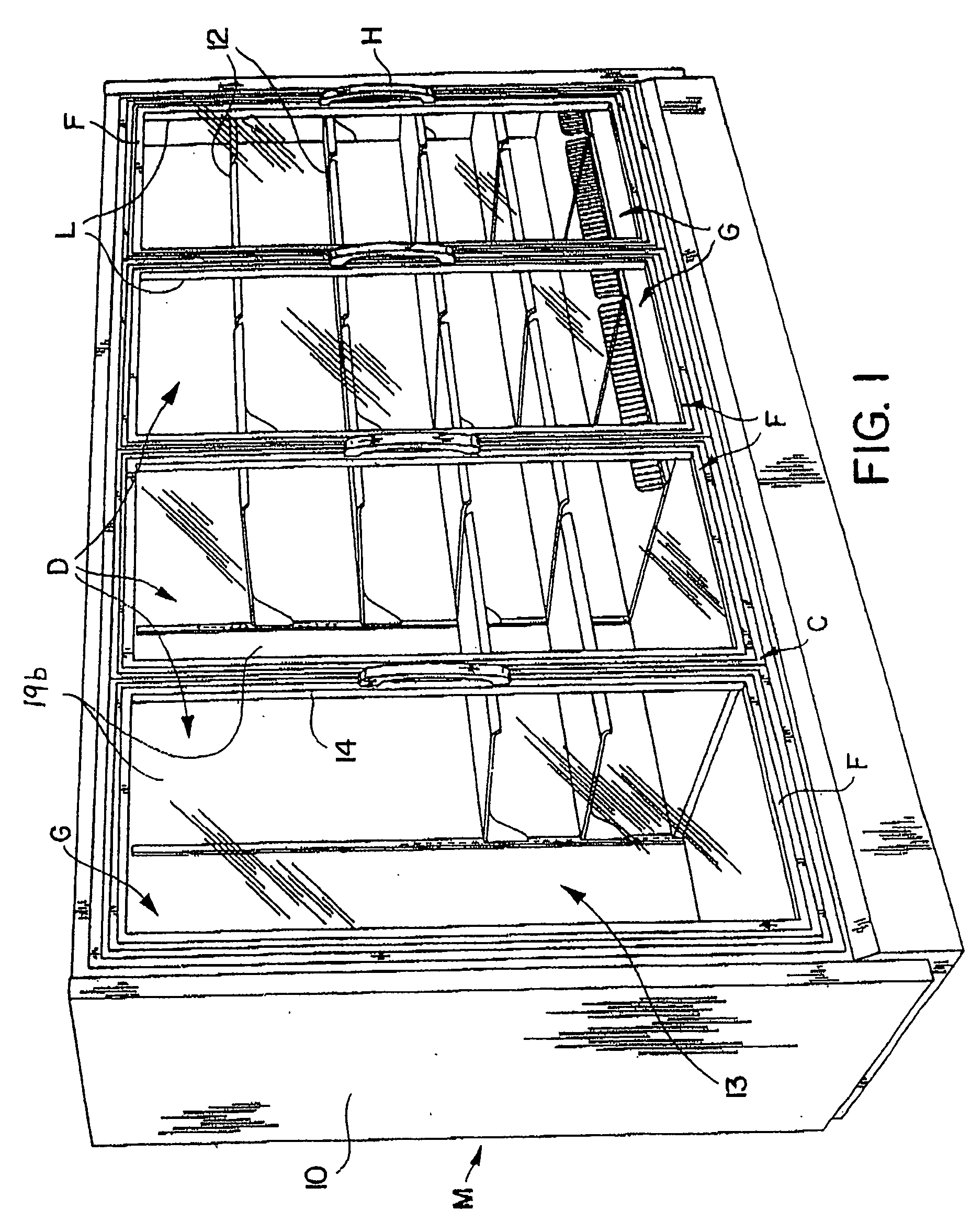

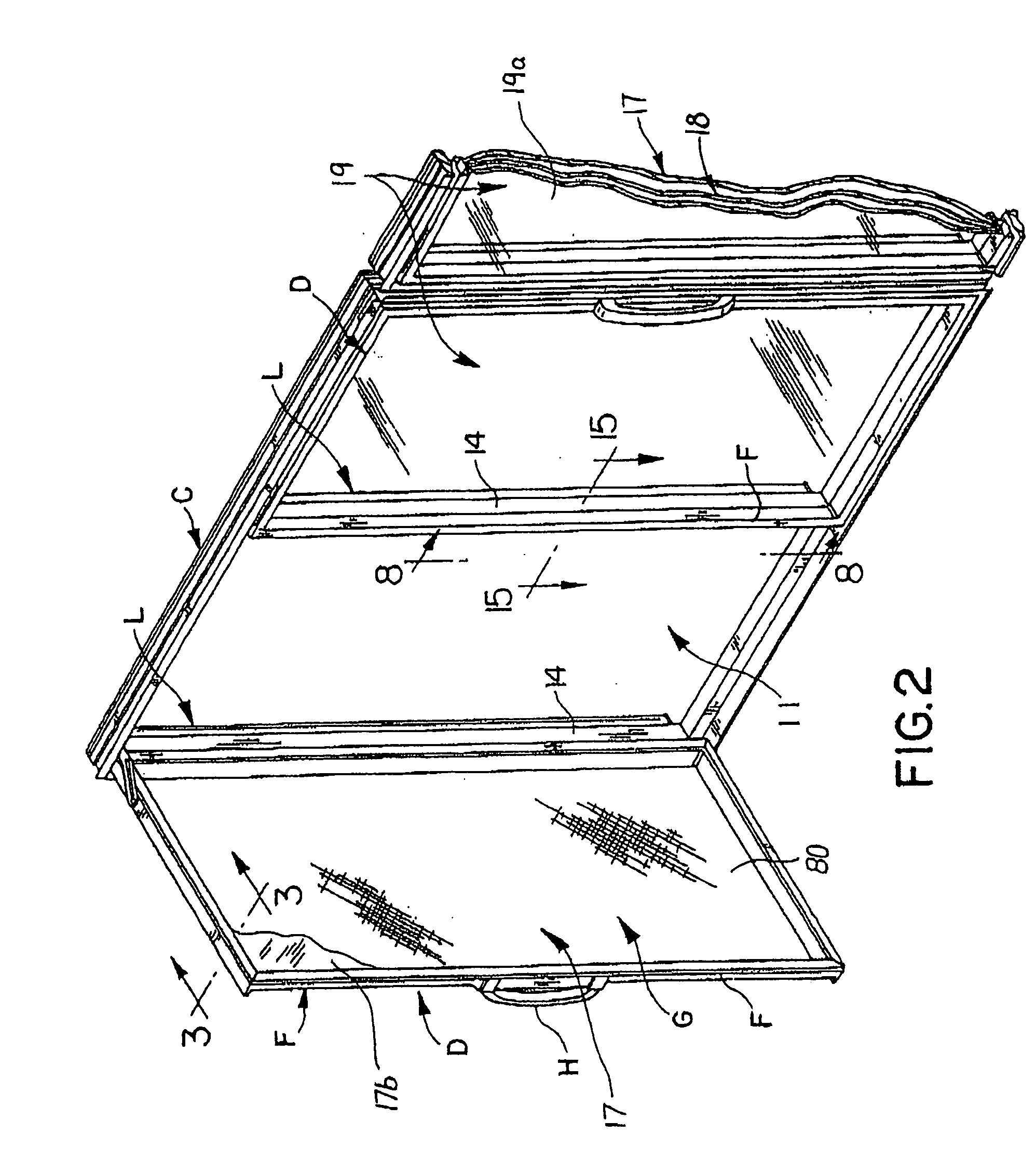

Merchandisers having anti-fog coatings and methods for making the same

a technology of anti-fog coating and merchandiser, which is applied in the direction of lighting and heating equipment, other chemical processes, domestic cooling equipment, etc., can solve the problems of obscuring the view of the product in the merchandiser, poor thermal insulation of glass and plastic, and condensation of moisture in the air spa

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

example 1

[0121] To illustrate the preparation of an abrasion resistant anti-fog coating with a hydrophilic surface. Part A was mixed using simple mixing, namely, a magnetic stir bar and plate with Part B. Part A comprised about 28.1 grams Desmodur N-75 (Bayer) well mixed with about 21.9 grams of diacetone alcohol. Part B comprised about 37.8 grams of diacetone well mixed with about 11.0 grams PEG-90, 0.2 grams dibutyltin dilaurate, and DC-57 additive (Dow Corning). The mixture was immediately applied to a 4″ square of Lexan polycarbonate, via an airbrush. The mixture was then allowed to stand at ambient conditions for about 10 minutes. It was then baked for one hour at 125° C. The sample had excellent anti-fog properties when blown on. A 100-cycle taber abrasion test resulted in a haze of less than 5% using a dual, 500-gram load and a CS-10F abraser wheel. Note that the light transmittance of the coated sample exceeded the uncoated polycarbonate (approx. 92% before coating application). Sepa...

example 2

[0122] Part A was mixed with Part B using simple stirring, namely, a magnetic stir bar and plate to form the mixture. Part A comprised 28.1 grams of Desmodur N-75 (Bayer) well mixed with 21.9 grams of diacetone alcohol. Part B comprised 35.8 grams of diacetone well mixed with 13.9 grams of polyethylene glycol-180, 0.2 grams of dibutyl tin dilaurate, and 0.05 grams of DC-57 manufactured by Dow Corning. The mixture was immediately applied by flow-coating to a 4″ square of Teflon coated metal, and allowed to stand at ambient conditions for about 5-10 minutes. The cooled, cured film was peeled from the teflon surface and wrapped around a 0.5″ steel rod to observe the flexibility of the film. No crazing or marring was observed even after wrapping the cured film around itself multiple times. The film shows excellent anti-fog properties when blown on or exposed to changes in humidity and temperatures. Condensed water vapor reduces clarity after a few minutes of exposure. The film fills lig...

example 3

[0123] Example 3 illustrates the preparation of a water-repellant, anti-fog coating for low-temperature usage. In a 1-L beaker equipped with a magnetic stirrer and a heating mantle, about 200 grams Baxenden 7683 obtained by Baxenden was stirred with about 281 grams of diacetone alcohol to produce a solution of blocked polyisocyante in solvent. The solution was then heated to 60° C. To the heated, stirring solution was added a solution of 179 g of PEG-4600 in about 179 grams of diacetone alcohol. The solution was stirred and maintained at 60° C. for about 10 minutes. Then 1.6 grams each of dibutylyin dilaurated, and DC-57 additive (Dow Corning) were stirred in to produce a coating composition. The heated mixture was then applied to glass panels via flowcoating, and allowed to hang vertically at ambient conditions for 5 minutes. Samples were then baked for about 25 minutes at 150° C. Subsequently, the cooled, cured samples were exposed to −25° C. for 10 minutes, and then exposed to am...

PUM

| Property | Measurement | Unit |

|---|---|---|

| temperatures | aaaaa | aaaaa |

| temperatures | aaaaa | aaaaa |

| temperatures | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com