Device for driving an endless belt and image forming apparatus using the same

a technology of endless belts and forming apparatuses, applied in the direction of electrographic processes, instruments, gearing, etc., can solve the problems of insufficient accuracy of inability to provide the accurate inability to accurately provide the diameter of the drum, etc., to achieve accurate register of toner images and rotate stably

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0054] To better understand the present invention, reference will be made to a specific, tandem image forming apparatus to which the present invention is applied. The image forming apparatus to be described is of the type including an endless belt for conveying a sheet while being pressed against photoconductive drums, and causing the surface of the belt and the surfaces of the drums contacting each other to move without any slip. The endless belt may be replaced with an intermediate image transfer belt, if desired.

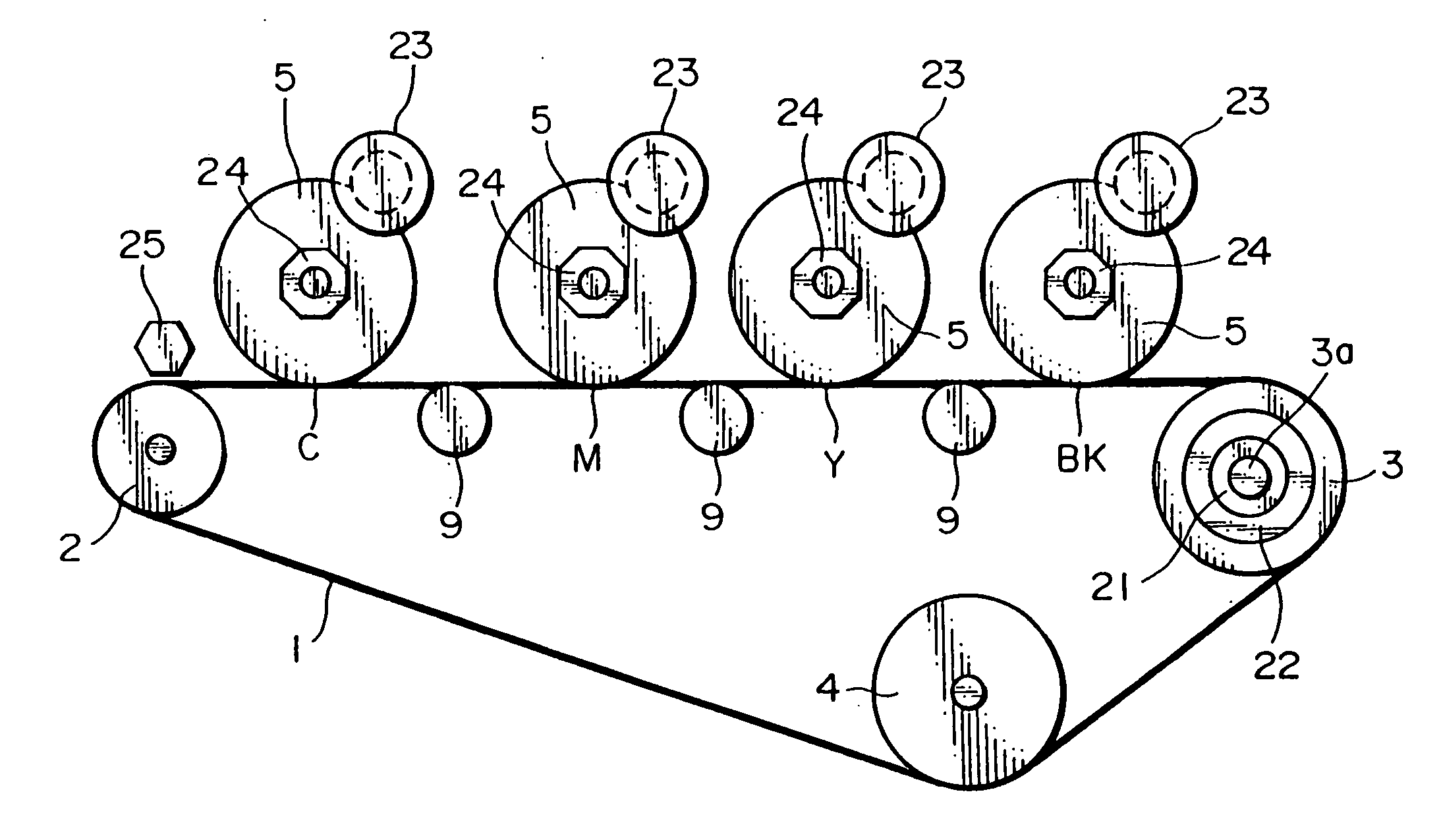

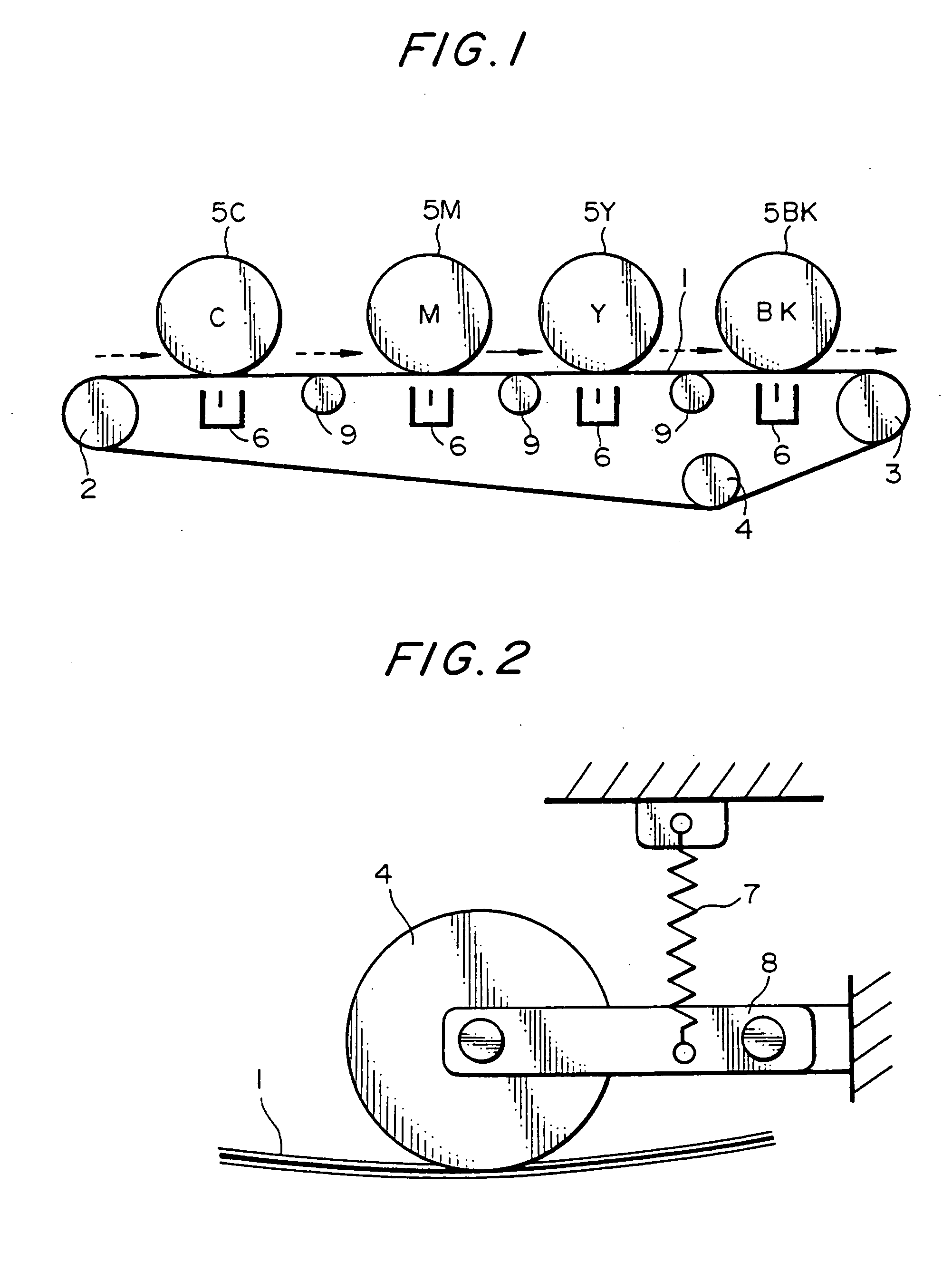

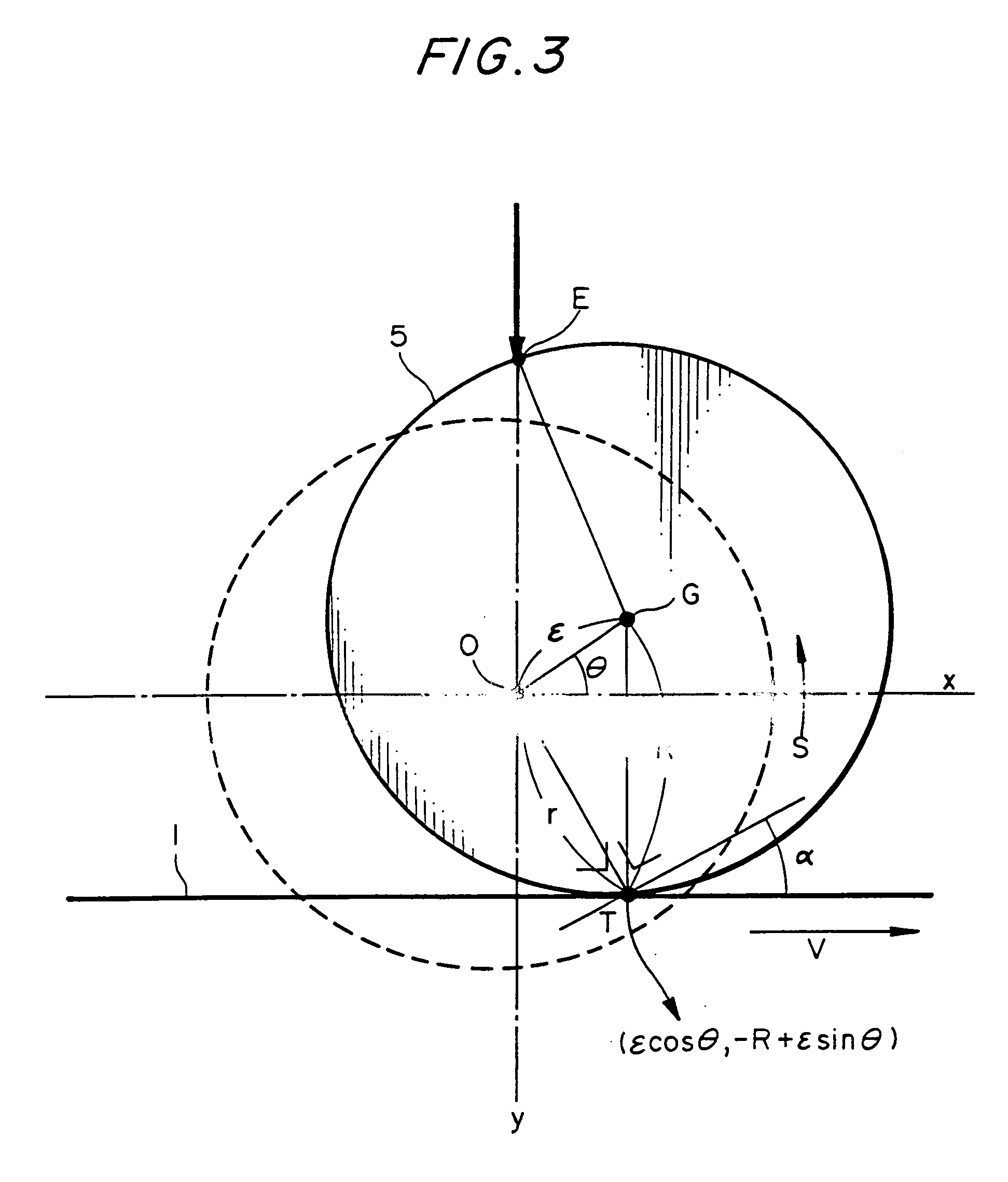

[0055] Referring to FIG. 1 of the drawings, a conveying section included in the image forming apparatus is shown. As shown, an endless belt 1 is passed over a drive roller 3, a driven roller, and a tension roller 4. Four photoconductive drums 5C, 5M, 5Y and 5BK each face a particular charger 6 with the intermediary of the belt 1. The drums 5C, 5M, 5Y and 5BK are assigned to cyan (C), magenta (M), yellow (Y), and black (BK). The chargers 6 are implemented by corona charge...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com