Coated diamonds for use in impregnated diamond bits

a technology of diamonds and diamonds, applied in the field of drill bits, can solve the problems of diamonds being lost from the bit, the life of both natural and synthetic diamonds is shortened,

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] In one aspect, the present invention relates to diamonds that have a specialized coating for use in diamond impregnated bits. In selected embodiments, the coating is a boride, nitride, or carbide of a group IVA, VA, or VI transition metal (Ti, Zr, Hf, V, Nb, Ta, Cr, Mo, W, or mixtures thereof). In particular embodiments, the coating is a silicon carbide. Other silicon coatings may be used as well. Further, those having ordinary skill in the art will recognize that other coatings may be used. The present inventors have discovered that by providing a strongly bonded wettable coating for the diamonds, enhanced diamond bonding and / or retention strength results, improving the performance of the impreg bit.

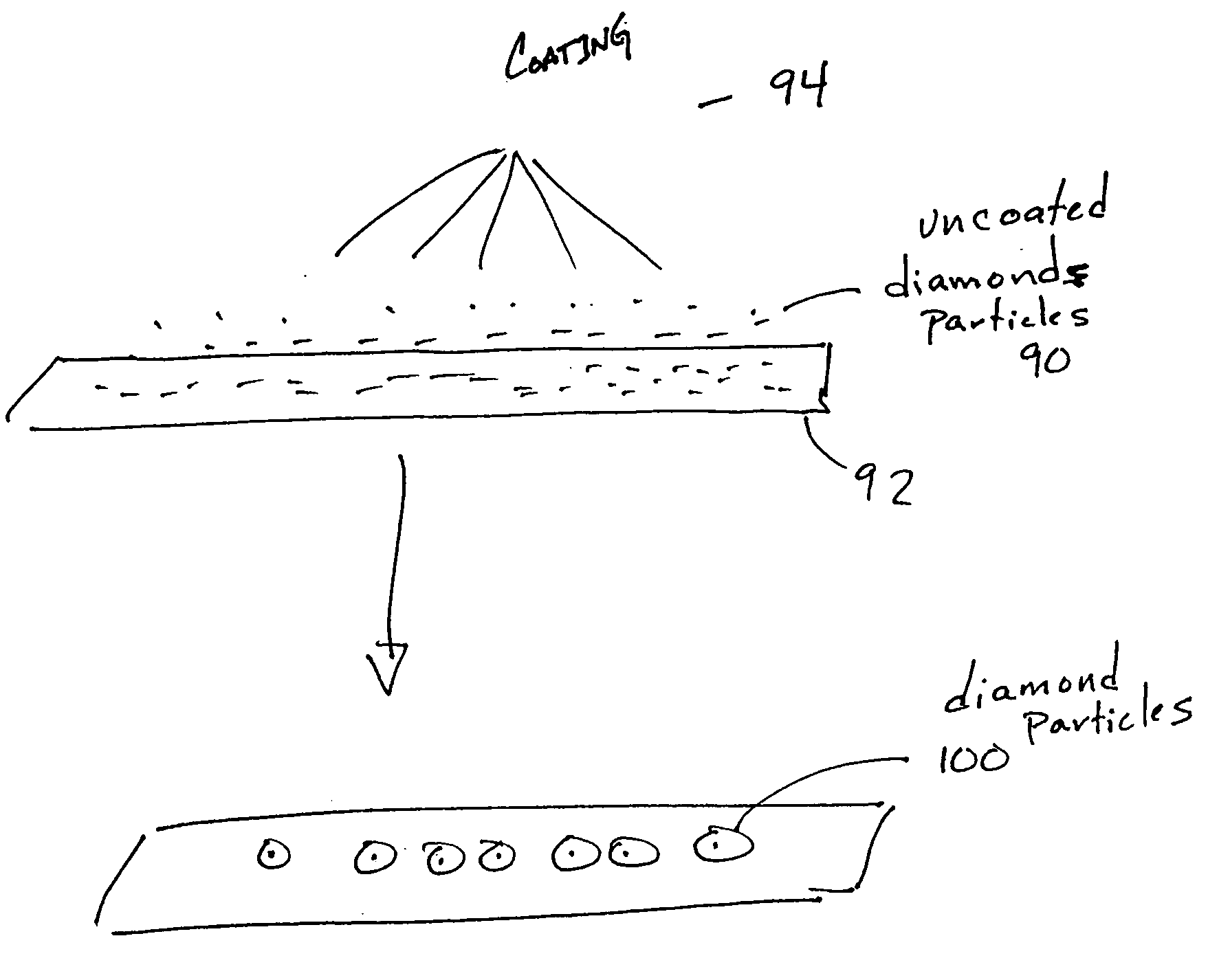

[0026] In one embodiment of the invention, coated diamonds 100 are manufactured prior to the formation of the impregnated bit, as shown for example in FIG. 3. In this embodiment, uncoated diamond particles 90 are placed on a work surface 92. The diamond particles can be natural,...

PUM

| Property | Measurement | Unit |

|---|---|---|

| temperature | aaaaa | aaaaa |

| temperature | aaaaa | aaaaa |

| temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com