Packing material and gland packing using the material and process for packing material

a gland and material technology, applied in the direction of thin material processing, engine sealing, textiles and paper, etc., can solve the problems of short packing life, high wasteful but also operating torque of rotating shaft, and earlier abrasion of rotating shaft, etc., to achieve high durability, withstand pressure ability, and lubricating property (low torque ability).

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

embodiment

[0071] Hereinafter, effect of the present invention is explained concretely by showing embodiment of the gland packing which relates to the present invention and measuring its capability. The present invention is not limited at all by the embodiment which is explained hereinafter.

Preparation of a Packing Material and a Gland Packing

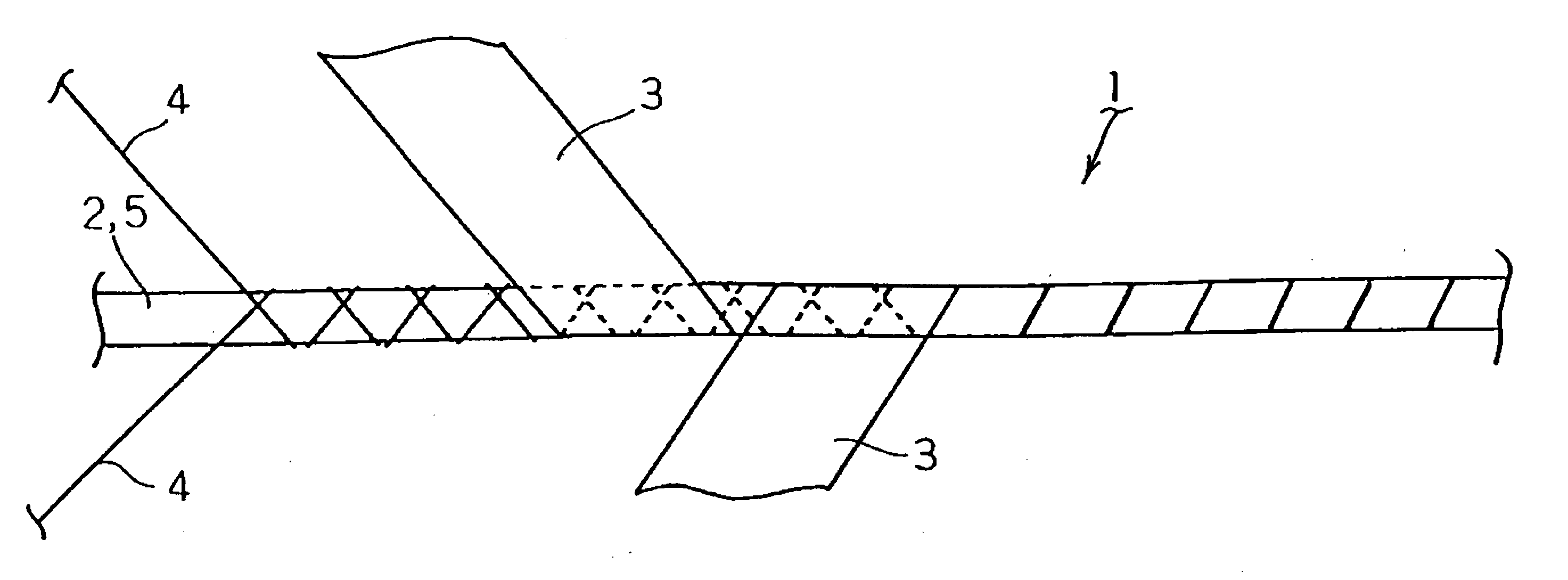

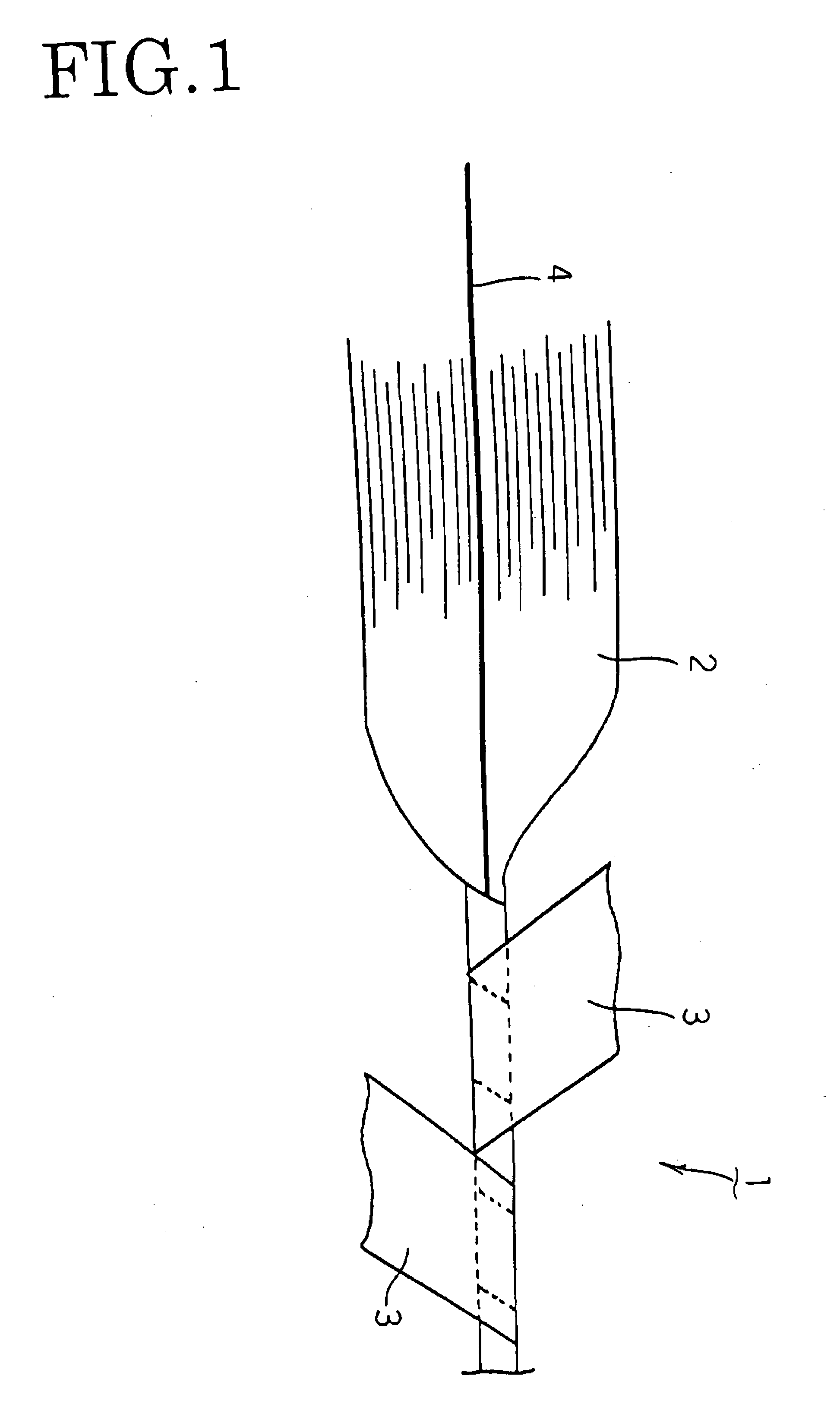

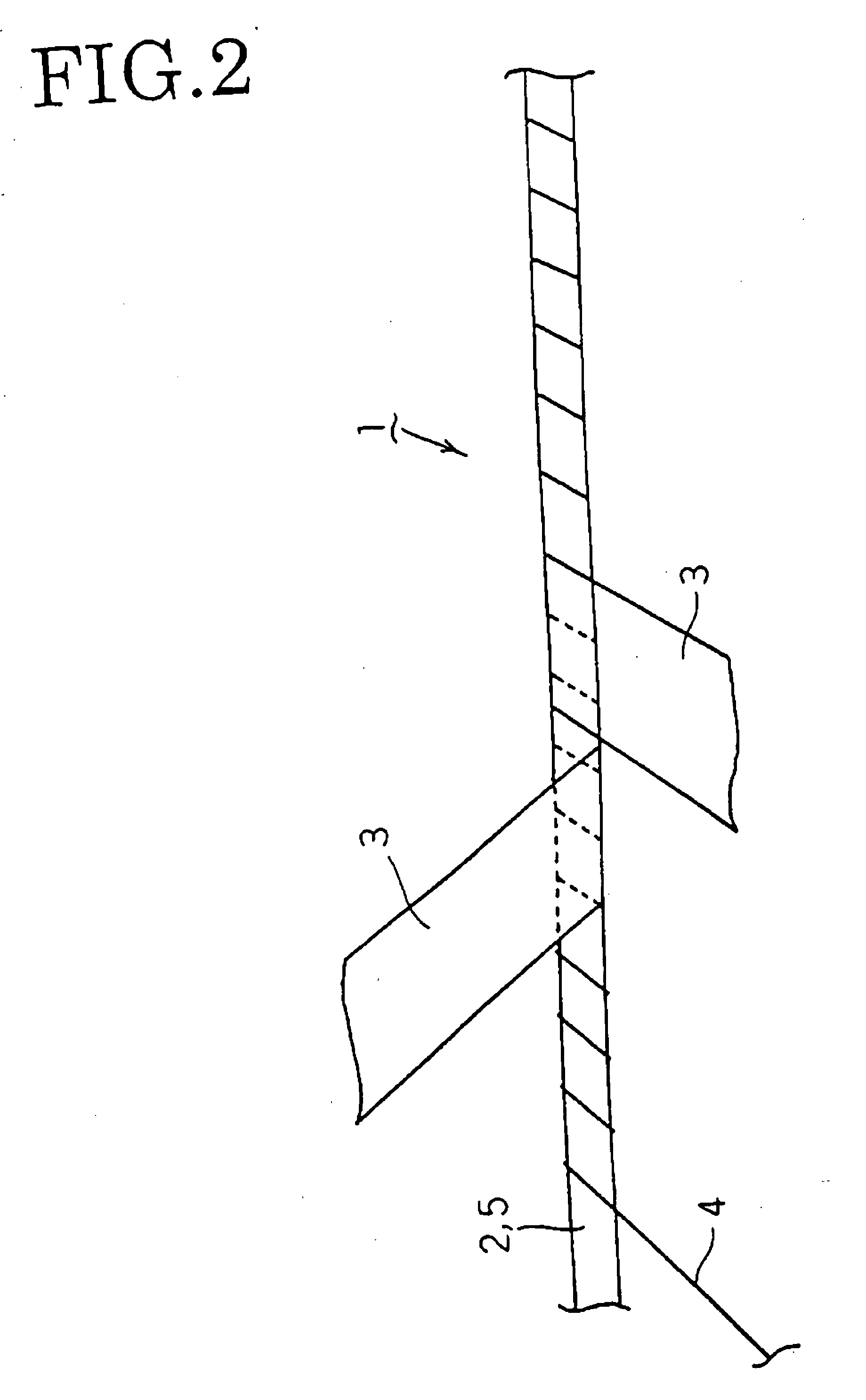

[0072] A packing material which relates to the said first embodiment was prepared by a bundle of strip carbon fiber which was sat as a base material and by a tape made from PTFE was winded on exterior surface of the base material which was twisted.

[0073] The width of the base material was 25 mm, and a diameter of twisted base material was 2.0 mm. The thickness of the tape which was made from PTFE was 0.08 mm, and its width was 13 mm. The packing material was prepared by winding the tape one fold on periphery of the twisted base material.

[0074] The packing material is braided, and a ring shaped gland packing (6) (refer to FIG. 8) is made by pressure f...

PUM

| Property | Measurement | Unit |

|---|---|---|

| speed | aaaaa | aaaaa |

| temperature | aaaaa | aaaaa |

| temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com