Design for manufacturability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] Overview

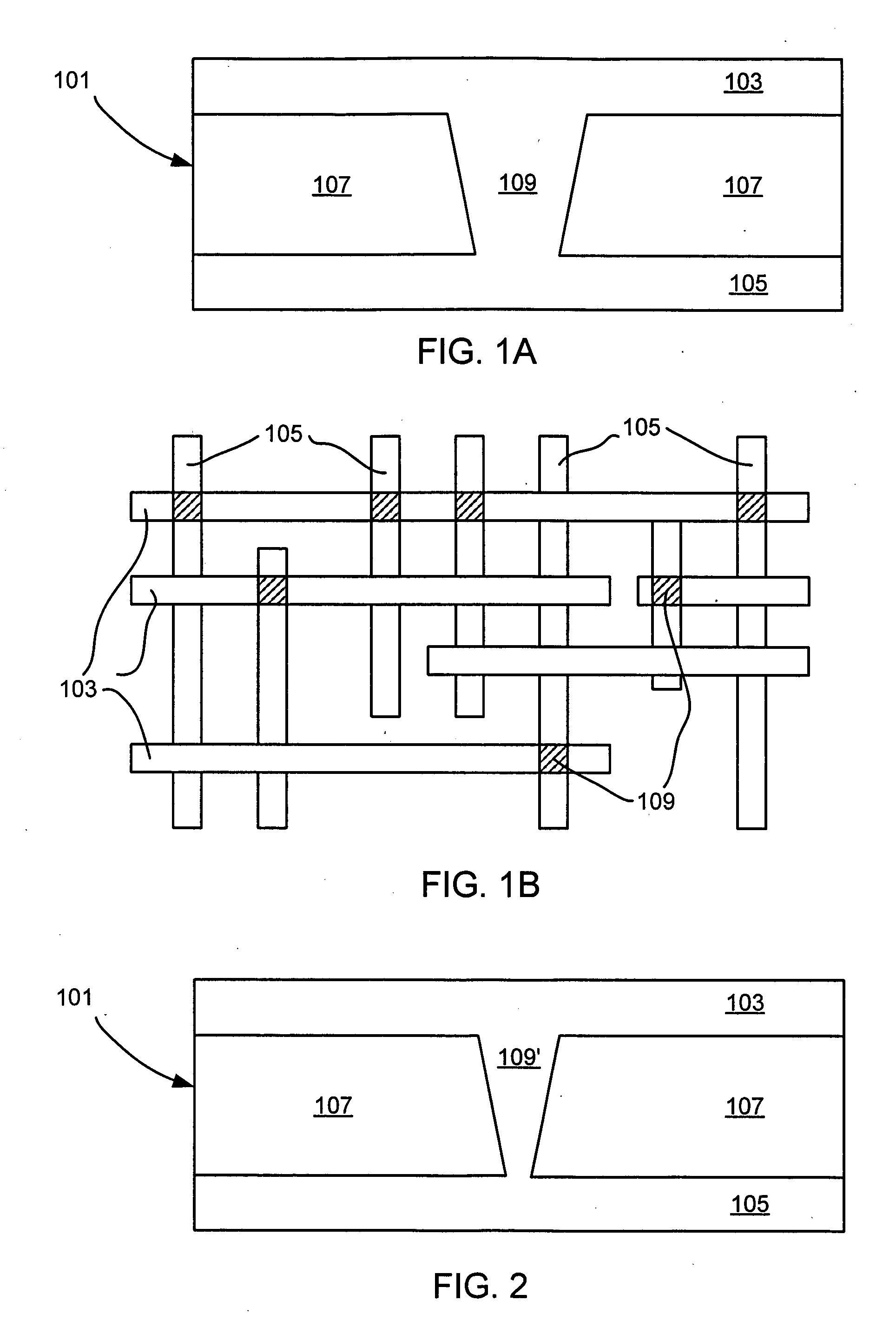

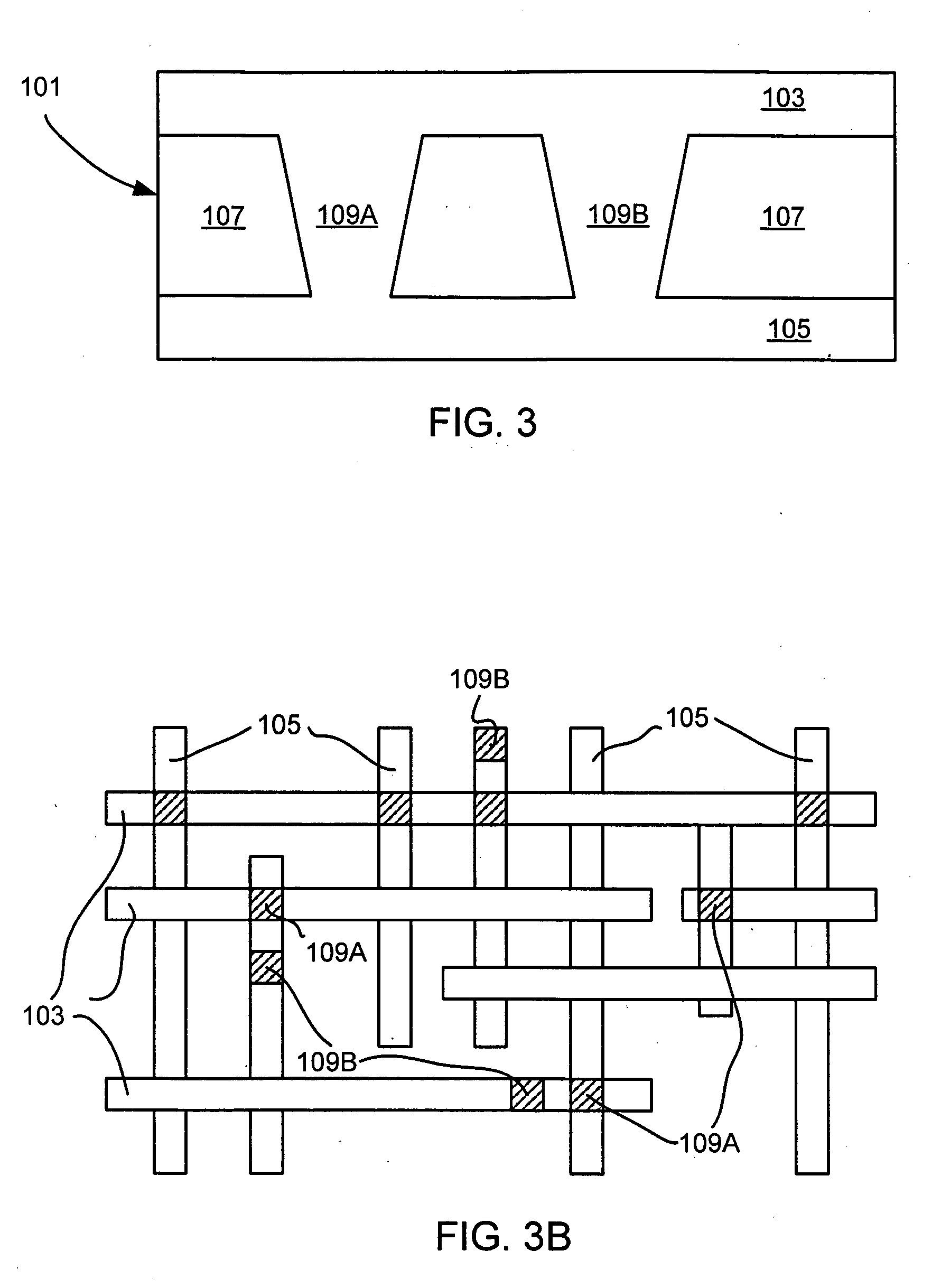

[0022] Various embodiments of the invention relate to techniques for modifying an existing microdevice design to improve the manufacturability of the microdevice. The improvements to manufacturability may result in an improved yield for the microdevices (that is, fewer failures per manufactured microdevice). The improvements may also result in better operating performance of the microdevice, lower costs for manufacturing the microdevice, or a combination of two or more of these features.

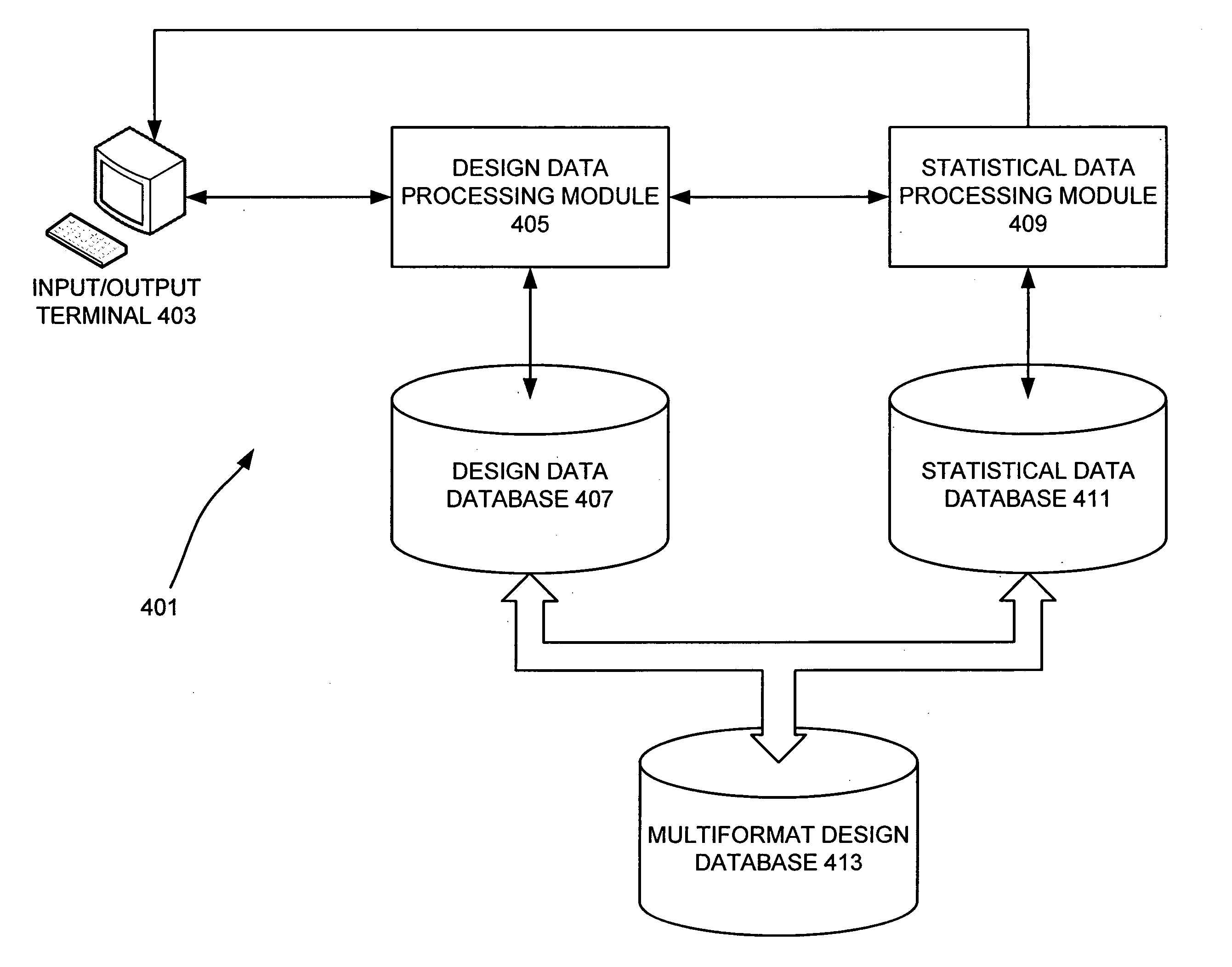

[0023] According to different embodiments of the invention, manufacturing criteria or process information associated with data in a design are provided to a database designed to receive such data. The associated design data then is identified and provided to the microdevice designer, who may choose to modify the design based upon the manufacturing criteria. Hints suggesting possible corrections, based on other criteria in a statistical database or historical use of the database, may ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com