Integrated dehumidification system

a dehumidification system and integrated technology, applied in the field of integrated dehumidification systems, can solve the problems of limiting latent cooling capacity, failure to control excessive indoor humidity, and often requiring more dehumidification of air, so as to achieve convenient installation, maintain indoor air quality, and efficiently and effectively dehumidify outside ventilation air

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

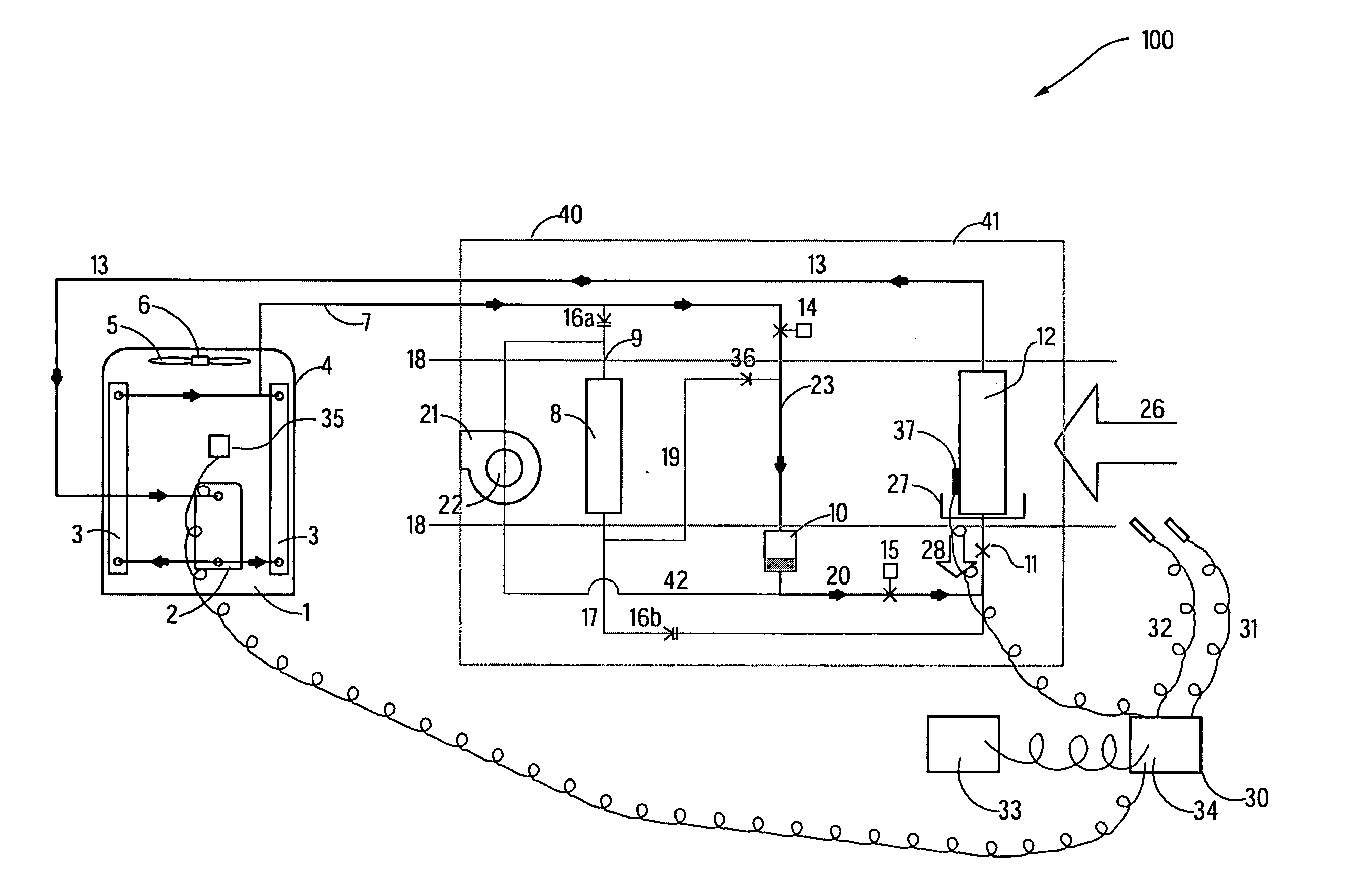

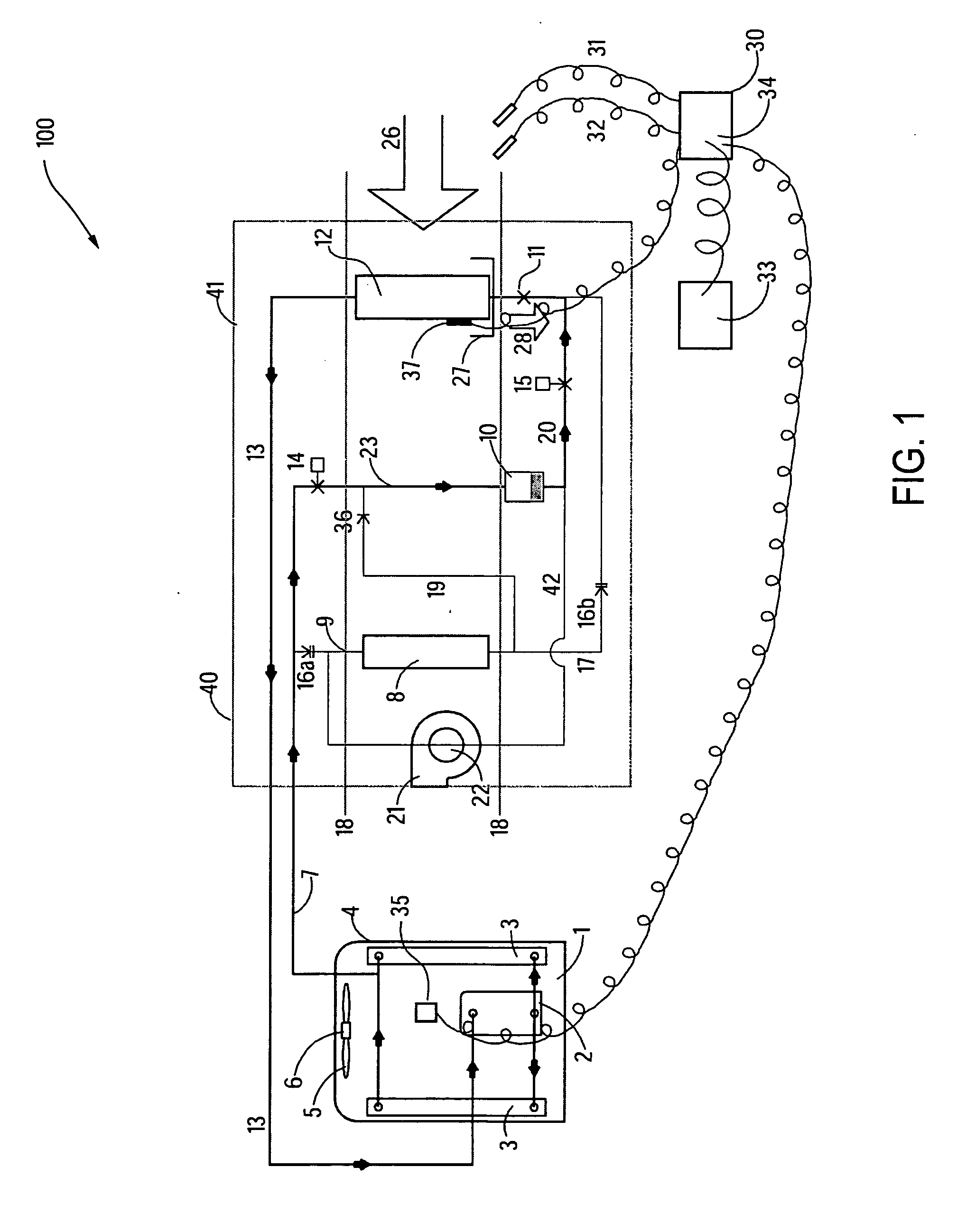

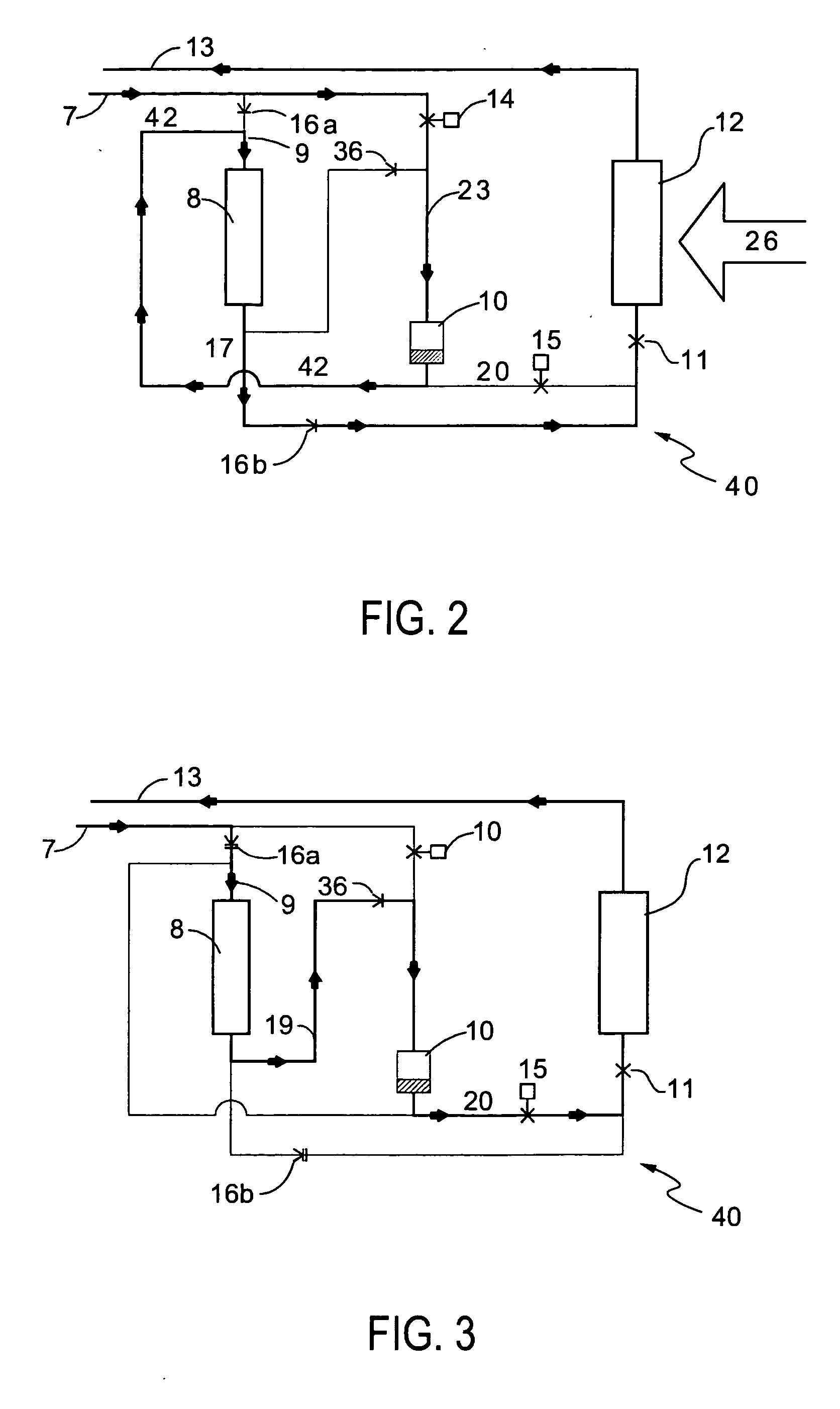

[0023] An exemplary embodiment of the systems and methods described in this disclosure comprises a set of vapor compression cooling components that can respond to a wide range of sensible and latent cooling loads, and control components with appropriate logic for automatically maintaining indoor temperature and relative humidity within close tolerances. The embodiment can condition either re-circulated indoor air, outside ventilation air supplied to buildings to maintain indoor air quality, or a mixture of the two. Exemplary components of such a system include a compressor, a condensing coil, a condenser fan, an indoor blower, an evaporator coil, a reheat coil, a refrigerant receiver, a thermostatic expansion valve, solenoid valves for switching refrigerant flow, a check valve, “pressure-differential check valves” (PDCV's), temperature and humidity sensors, and controls for selecting an operating mode based on sensed conditions.

[0024] With reference to FIG. 1, an integrated dehumid...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com