Method and apparatus for the preparation of alimentary soft granular caviar

a technology of soft granular caviar and food product, which is applied in the field of preparation of delicacy granular food product, can solve the problems of reducing the quantity of on-the-shelf product, reducing the quantity of product, and obtaining significant quantity of grains deviating from standard size, so as to achieve dietary organoleptic and ecological properties, and lowering the contamination of produ

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The unit for forming of ball-shaped grains is intended for production of black caviar, for instance, for forming ball-shaped grains 1-3 mm in diameter from an albuminous mixture. The following operations—tanning, coloring, gustatory addition—may be performed in the usual utensils or special containers.

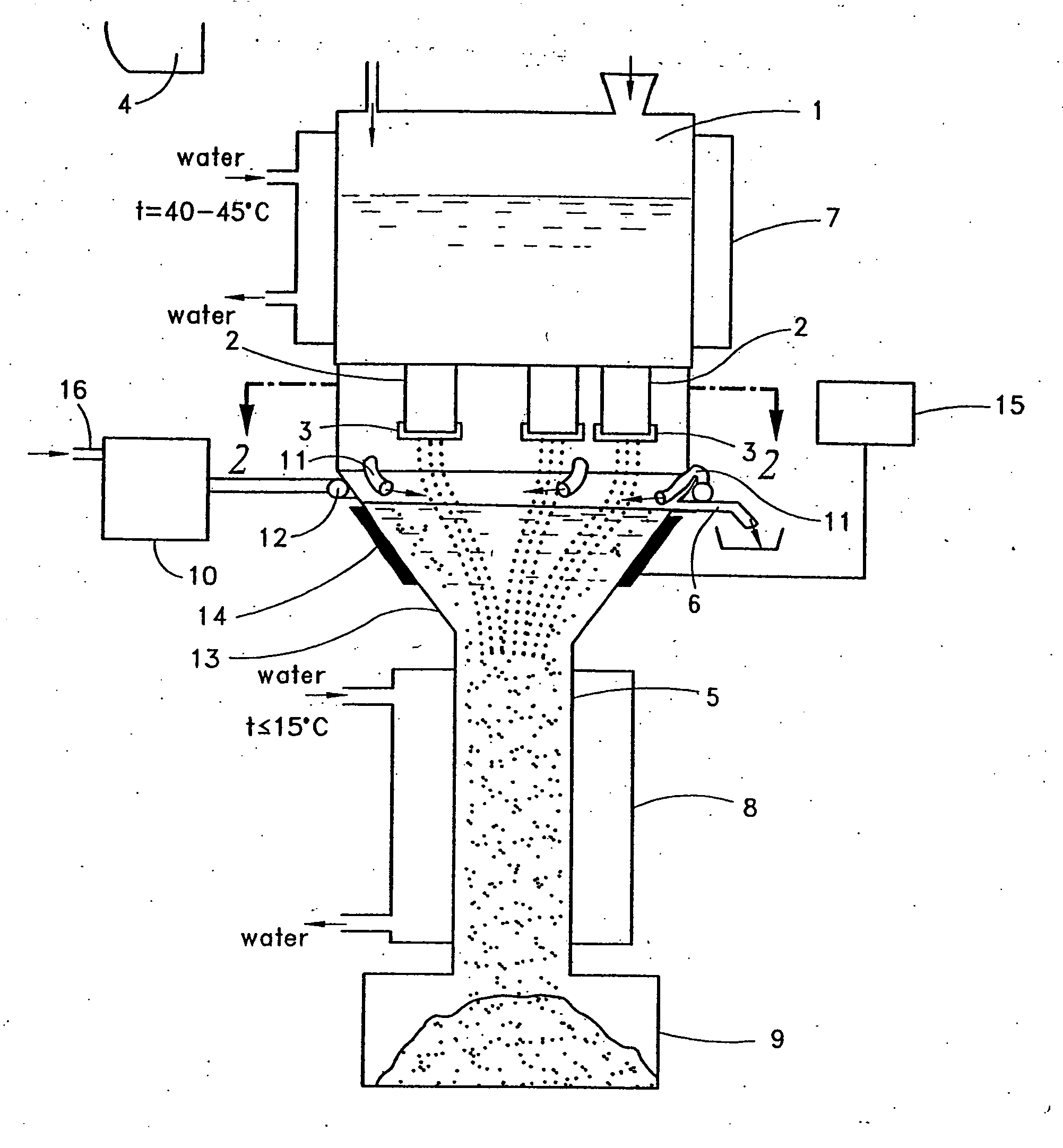

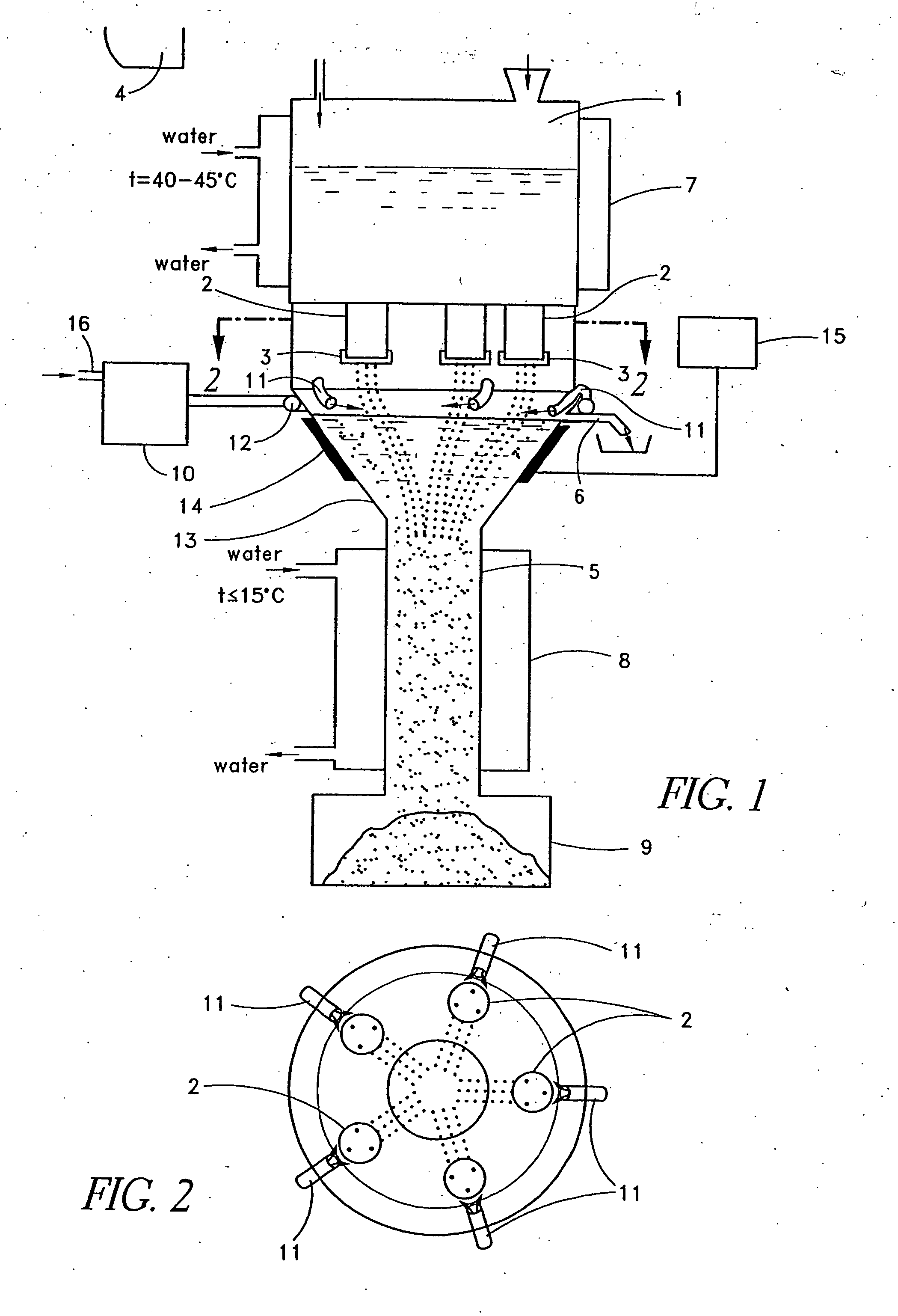

[0032] As is shown in FIG. 1, the device for manufacturing of alimentary soft caviar includes a cavity 1 for containing the basic solution of components to be supplied to the outlet pipes 2 with stream-forming heads 3 at the ends of the pipes, a source of gas pressure 4 connected to the cavity 1, a cylindrical granulating cavity 5 for the formation of caviar grains, connected to piping 6 for draining surplus formation liquid, attached axially to the cavity 1 beneath the outlet pipes 2. The cavity 1 with the basic solutions of components and the cylindrical section of the granulating cavity 5 are equipped with thermostatic means in the form of water jackets 7 and 8 located aroun...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com