Handle assembly for tool

a technology for tools and handles, applied in the field of handle assemblies for tools, can solve the problems of limiting the length of time during which the tool can be used continuously, difficult for a user of the tool to maintain a grip, and significant vibration, and achieve the effect of simplifying the assembly of the tool and reducing the cost of tool manufactur

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

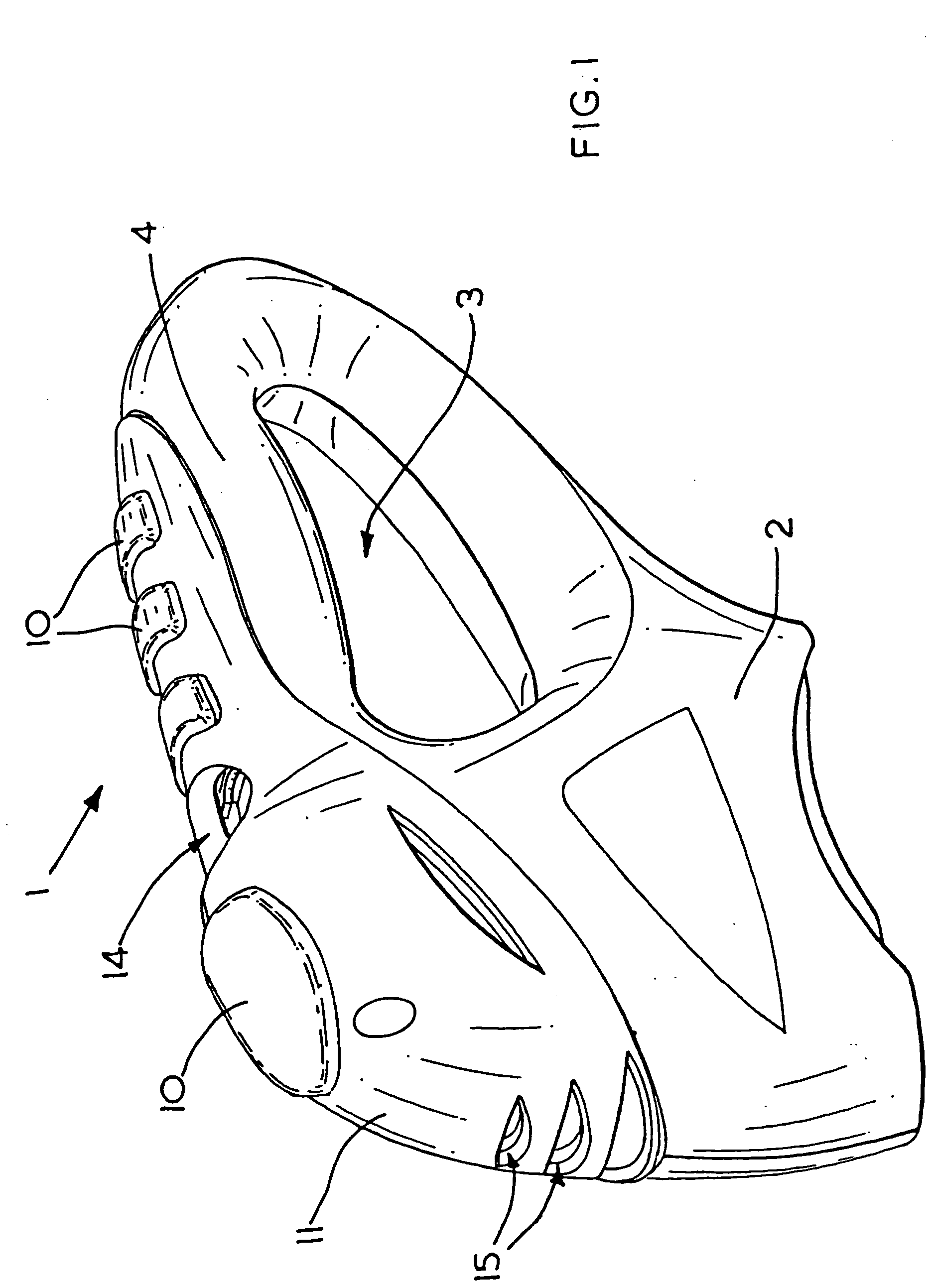

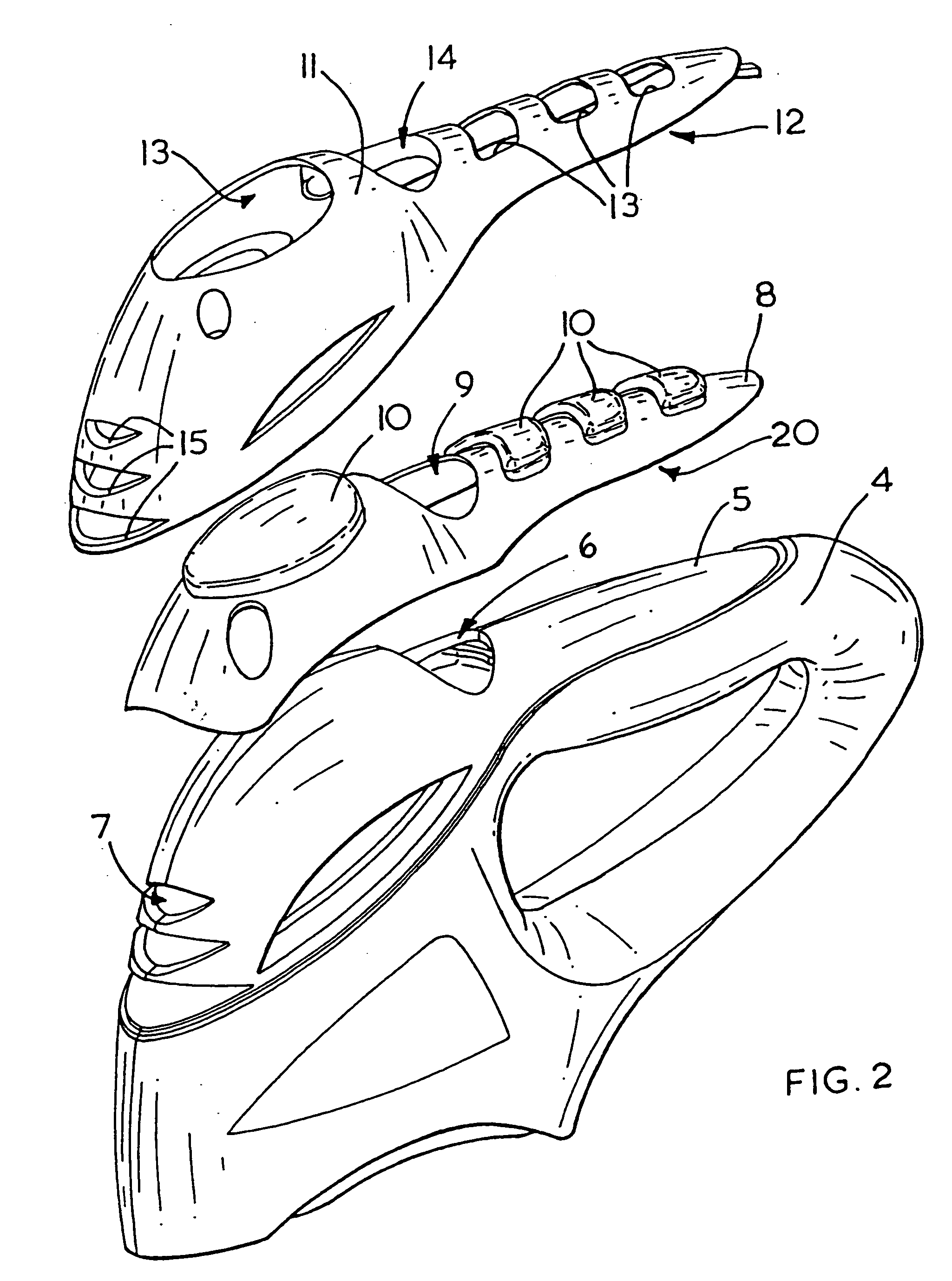

[0040] Referring to FIGS. 1 and 2, a power tool 1 such as a drill or jigsaw comprises a housing 2 defining an aperture 3 bounded on one side thereof by a handle 4, the housing 2 containing a motor (not shown) for actuating an output member such as a drill bit or jigsaw blade (not shown).

[0041] The housing 2 is formed from a generally durable plastics material, as will be familiar to persons skilled in the art, and has a recessed portion 5 on a generally smooth upper surface of the handle 4, the recessed portion 5 being provided with a recess 6 containing an actuating switch (not shown) for turning the tool 1 on and off. The housing 2 is provided with ventilation apertures 7 at one end of the recessed portion 5 to allow cooling of the interior of the housing 2.

[0042] A flexible sheet 8, of thermoplastic elastomeric material, such as a thin layer of polyurethane, having a coefficient of friction higher than that of the material from which the housing 2 is made, is formed by means of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com