Computer-aided three-dimensional bending of spinal rod implants, other surgical implants and other articles, systems for three-dimensional shaping, and apparatuses therefor

a technology of spinal rod implants and three-dimensional shaping, applied in the field of computer-aided design and construction of medical implants and to surgical procedures, can solve the problems of poor resolution of current clinical paradigm for designing and shaping surgical corrective instruments, high personnel intensity, and process that is both tiring and involving increased risks for patients, and achieves global accuracy.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

##ventive example 2

INVENTIVE EXAMPLE 2

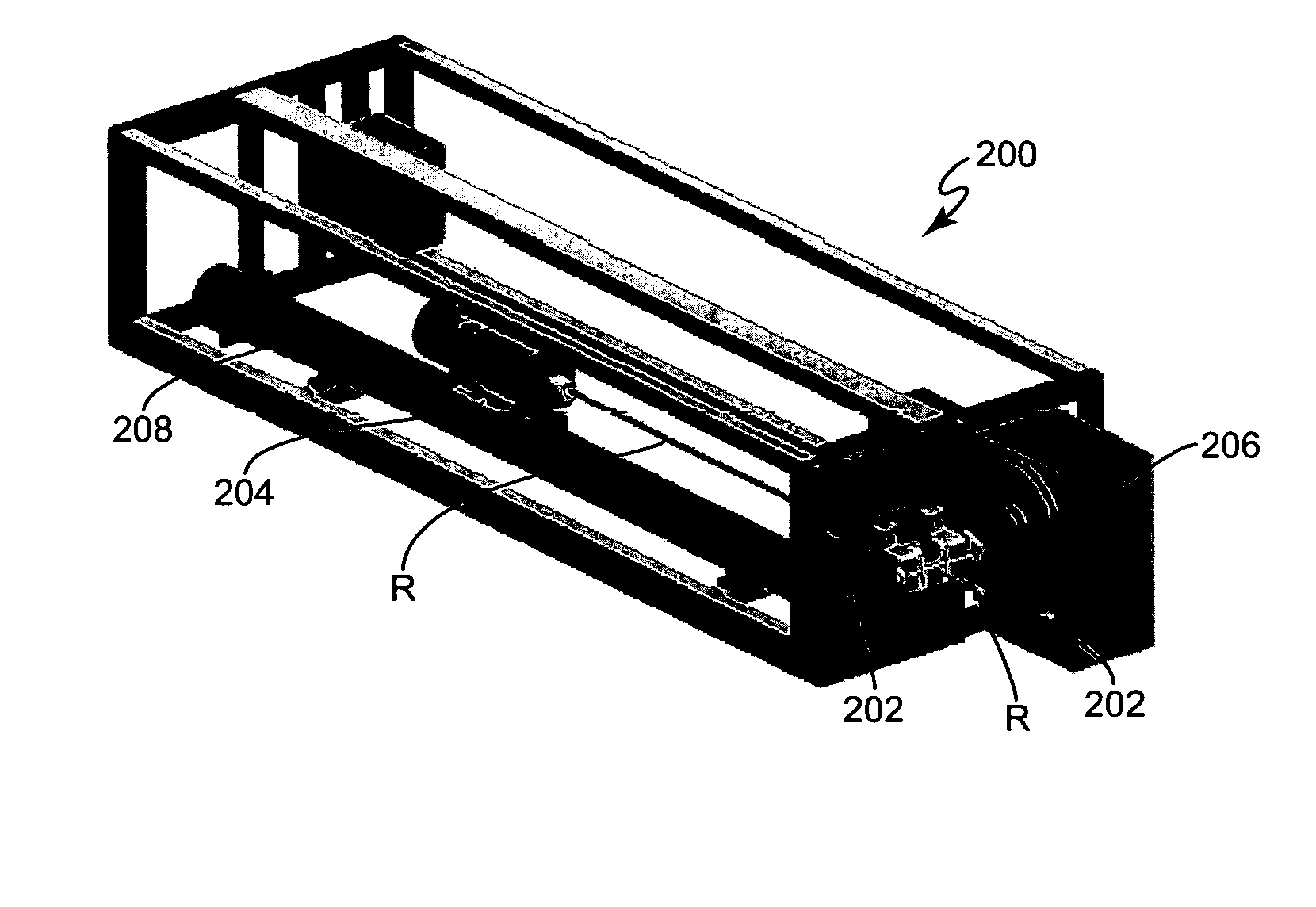

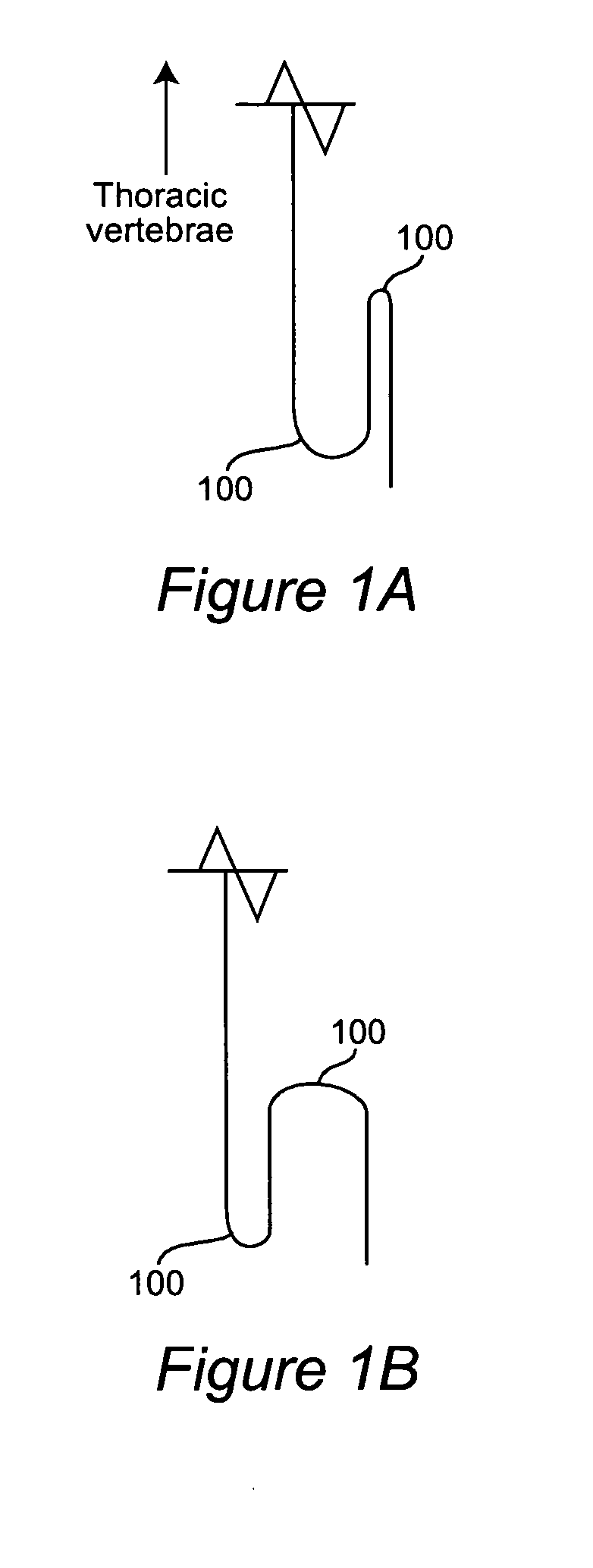

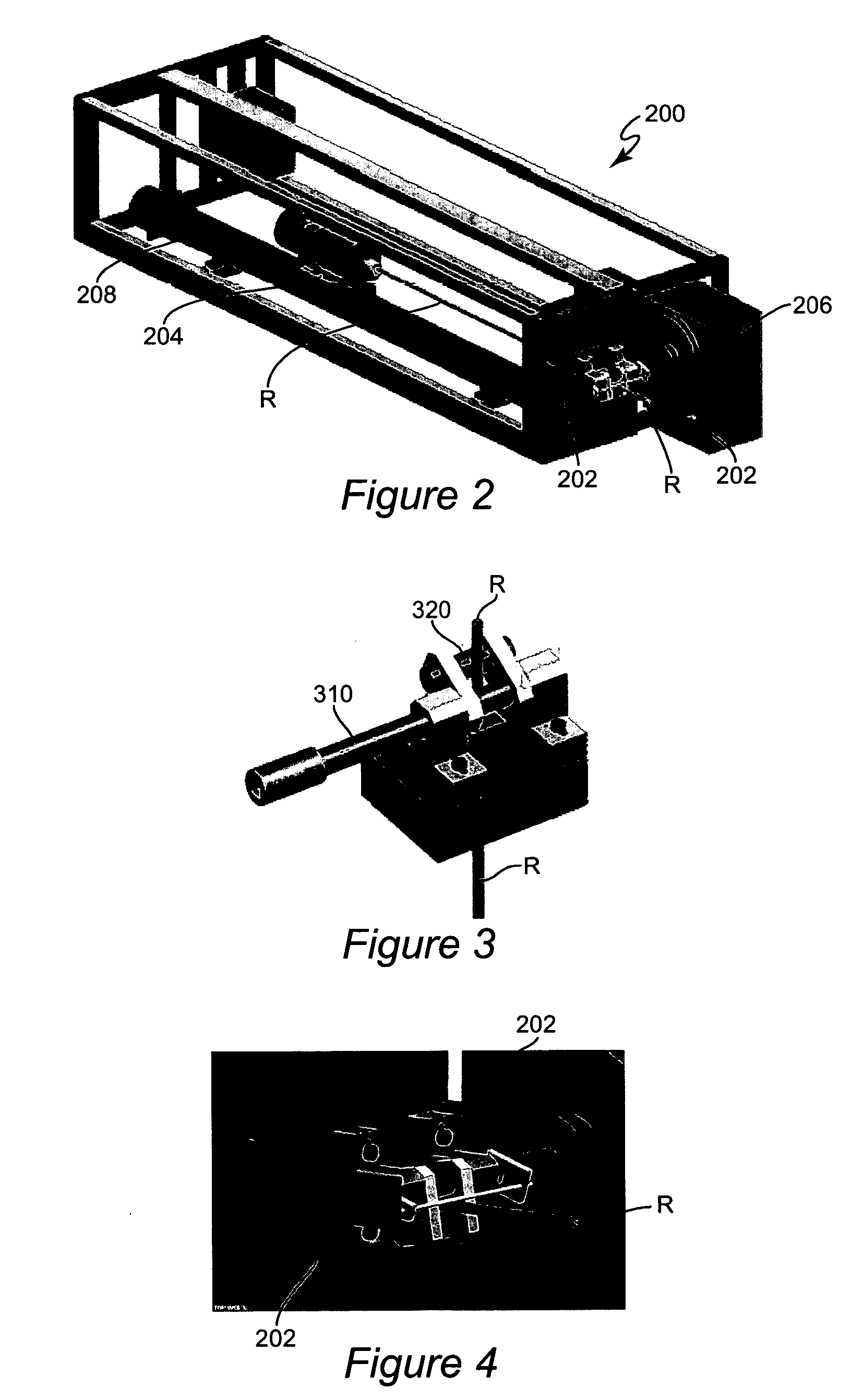

[0103] A preferred example of a use of the present invention is a method in which, in advance of surgical implantation, automated pre-screening of a three-dimensional bent shape is performed, including a determination of placement in the patient of the three-dimensional bent shape with reference to cooperating hardware placed, or to be placed, in the patient.

[0104] An example of cooperating hardware placed, or to be placed, in the patient is a pedicle screw, which is medical hardware conventionally in use, such as pedicle screw used in spinal surgery. An example of a three-dimensional bent shape is a bent spinal rod. The pedicle screws are used in attaching the spinal rod to the patient's body. In the invention, placing the bent spinal rod in the patient may be assisted by an inventive article that cooperates with the pedicle screw, such as a cap for the pedicle screw. An example of an inventive pedicle screw cap is a pedicle screw cap, comprising an article havi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| angles | aaaaa | aaaaa |

| angles | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com