Circuit board assembly employing solder vent hole

a technology of circuit board and solder vent hole, which is applied in the direction of printed circuit, printed circuit components, printed circuit manufacturing, etc., can solve the problem of no intimate metal-to-metal contact between metal substrates, and achieve the effect of relieving pressure in the cavity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

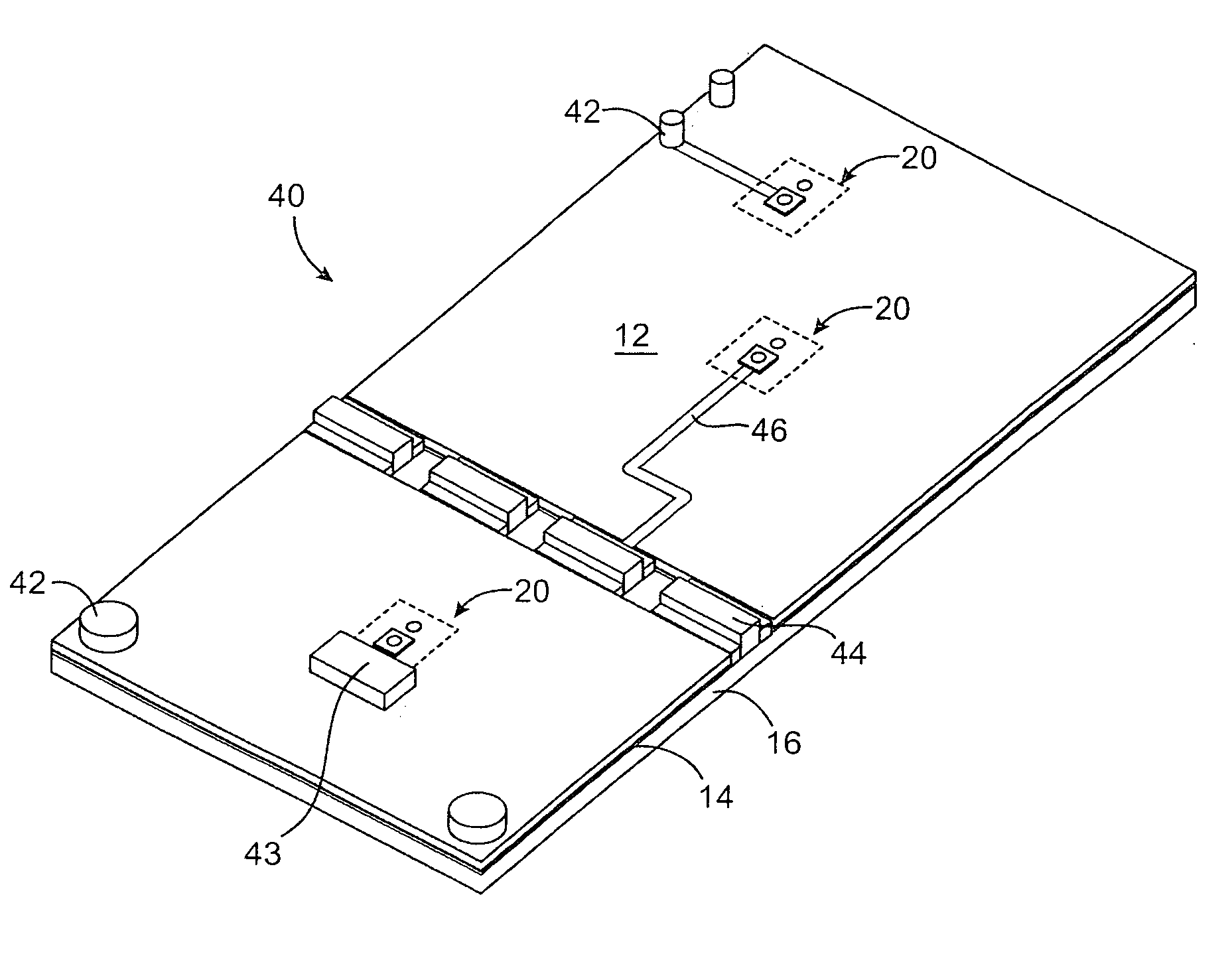

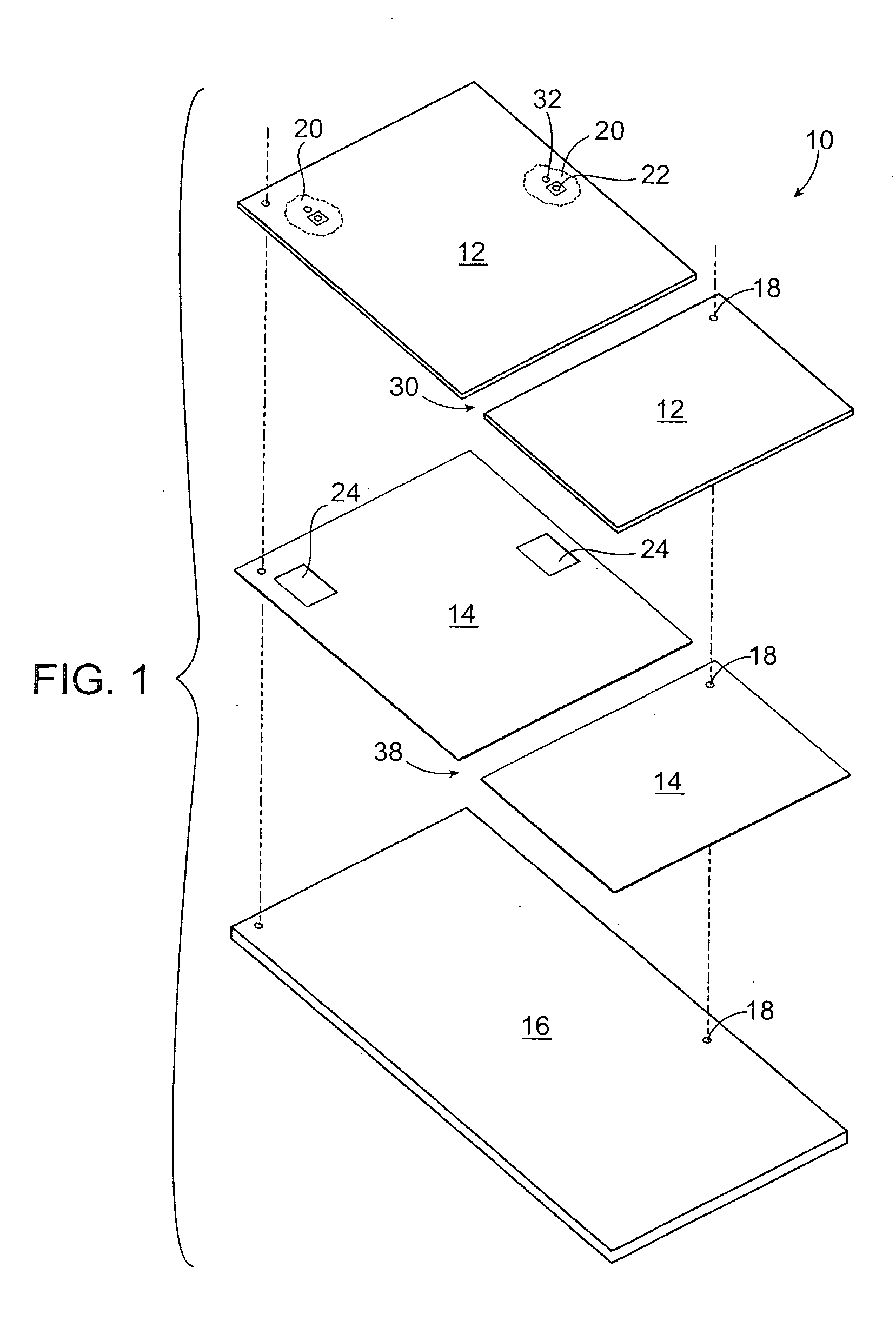

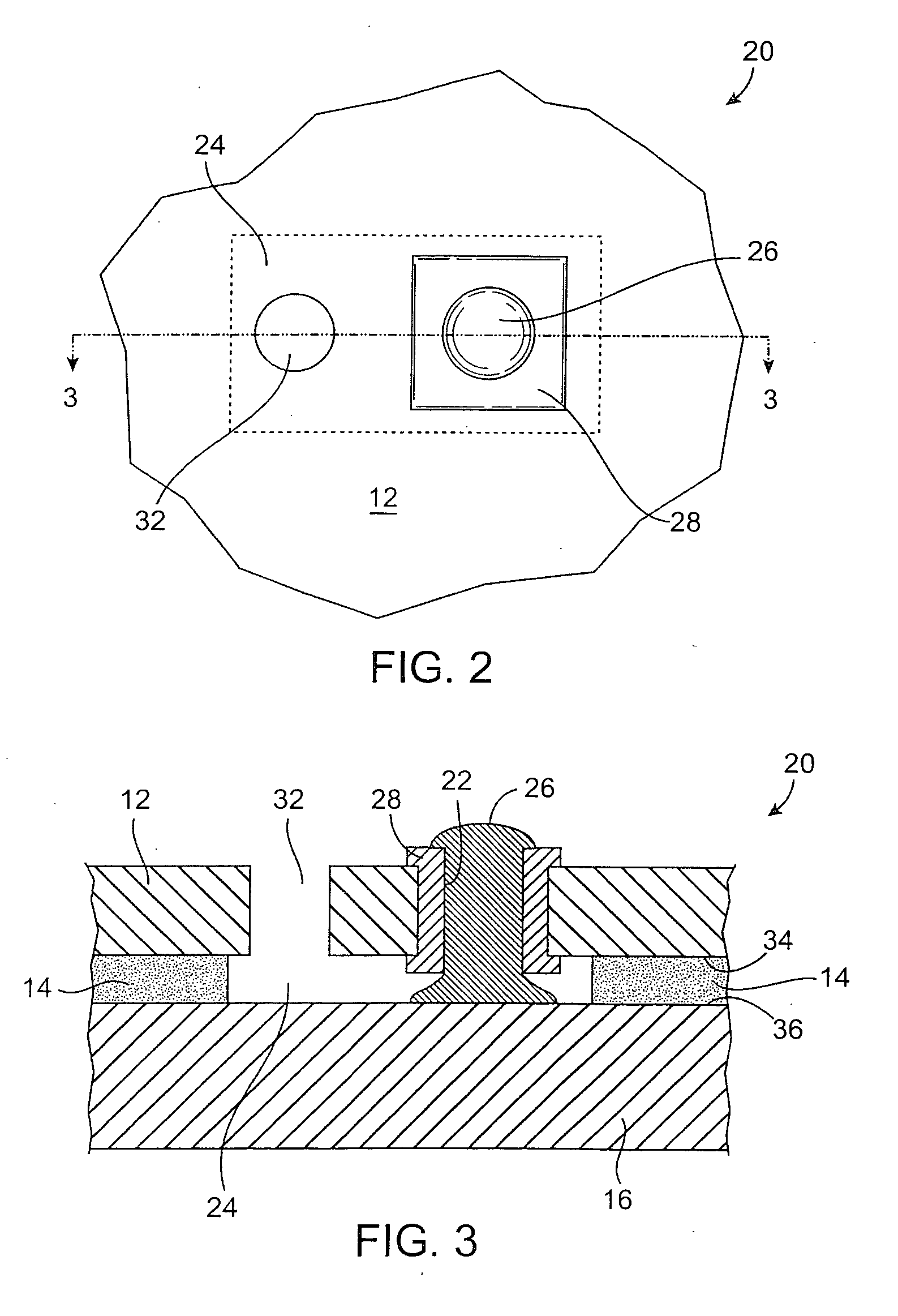

[0020]FIG. 1 is an exploded perspective view of an electronics assembly 10 in accordance with a preferred embodiment of the present invention. In this example, assembly 10 comprises printed circuit board (PCB) layer 12, nonconductive adhesive layer 14, and a conductive support substrate or pallet 16. Pallet 16 is composed of a good electrical and thermal conductor, preferably a metal such as copper. Printed circuit board layer 12 is attached to the conductive substrate 16 using the nonconductive adhesive 14 (as shown in FIG. 3). For example, a thermal set sheet epoxy 14 may be employed. The use of a thermal set nonconductive adhesive sheet (or preform) to attach a printed circuit board to a metal substrate is disclosed in U.S. Pat. No. 6,421,253 to Daniel Ash, Jr., issued Jul. 16, 2002, the disclosure of which is incorporated herein by reference in its entirety. The PCB layer 12 includes various active and passive electronic components (shown generally in FIG. 4) and in one preferre...

PUM

| Property | Measurement | Unit |

|---|---|---|

| conductive | aaaaa | aaaaa |

| electrically conductive | aaaaa | aaaaa |

| thermally conductive | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com