Method of manufacturing densified firelog from unwanted and diseased wood, and method of doing business regarding same

a technology of densified firelogs and unwanted and diseased wood, which is applied in the field of densified wood products, can solve the problems of driving down the value of wood materials for this purpose, and achieve the effects of reducing or reducing the effort to reduce or mitigate the fuel buildup, reducing the need to control the fuel buildup, and reducing the need for fuel reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

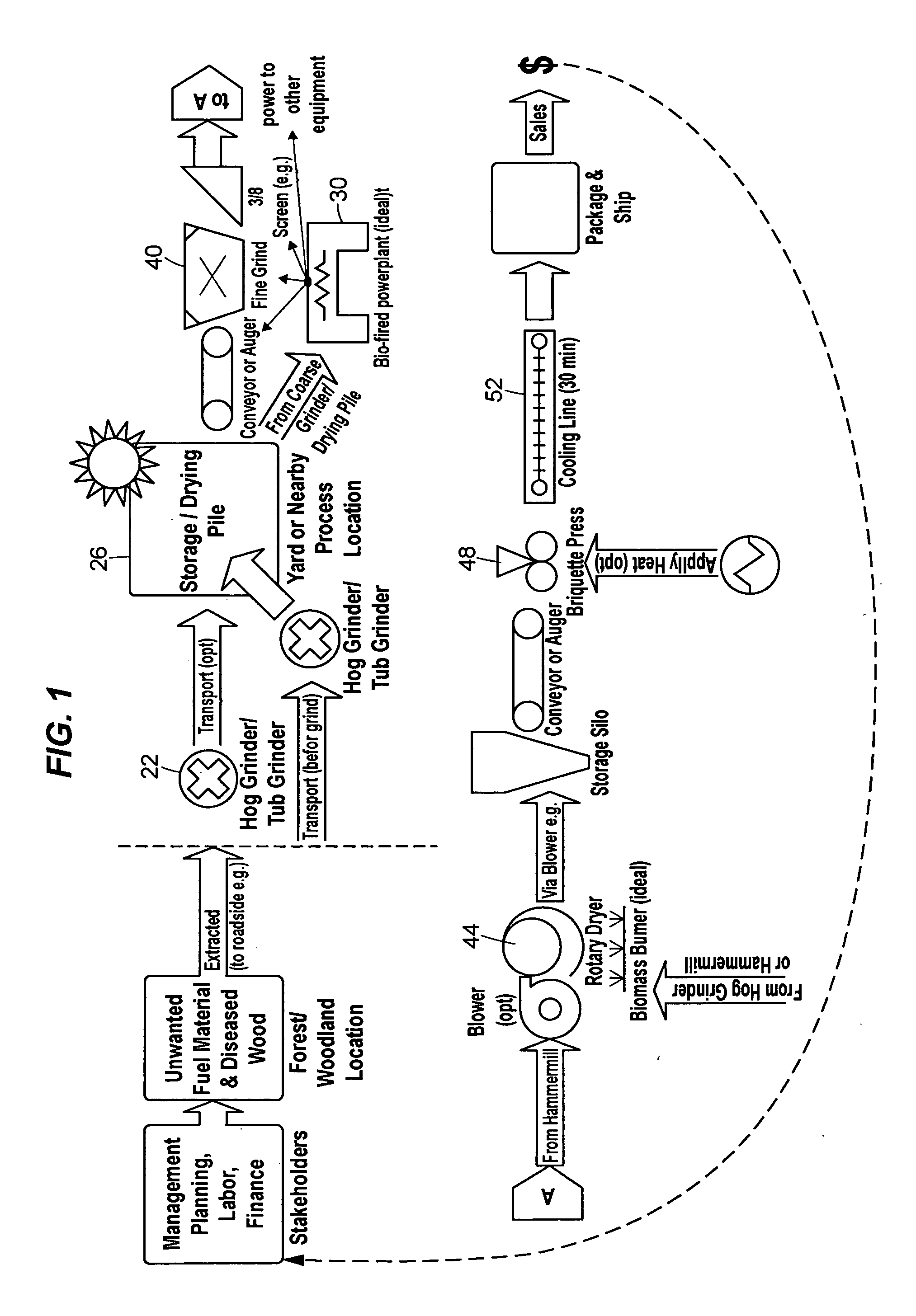

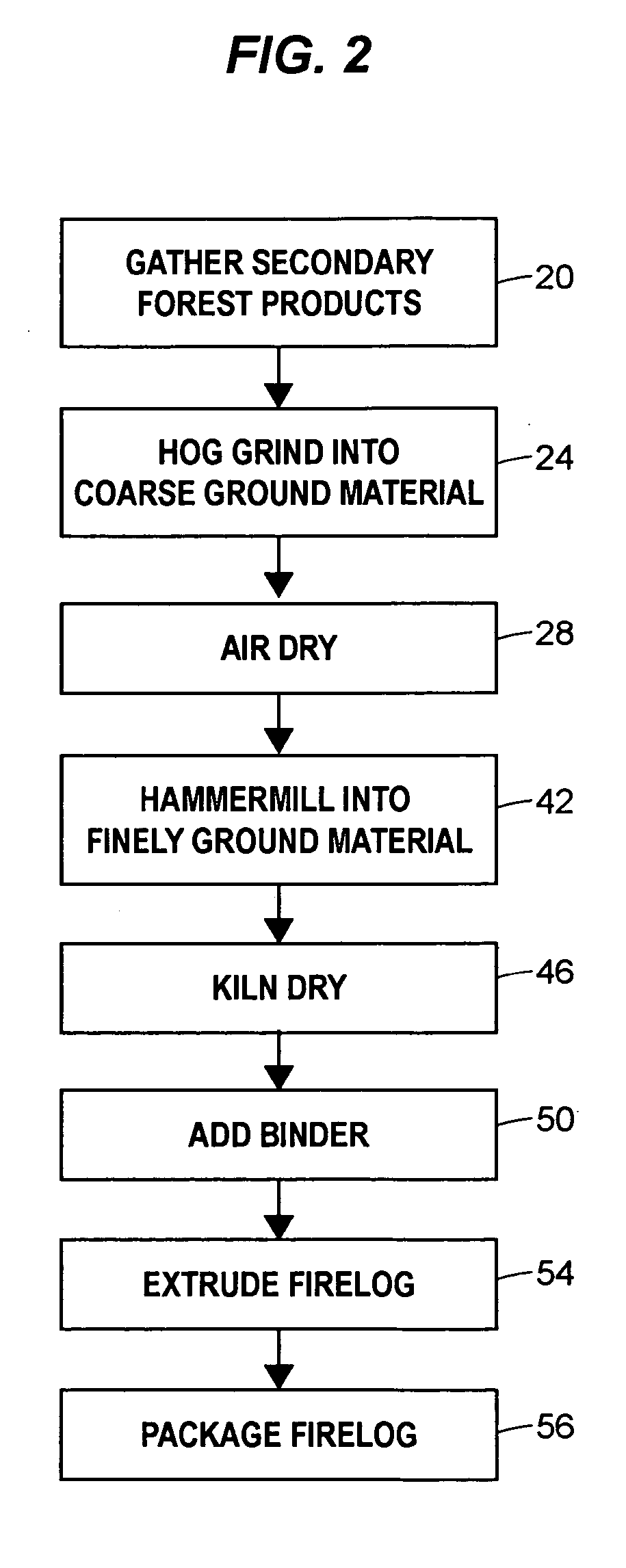

[0023] The methods and apparatus of the present invention will now be described with simultaneous reference to FIGS. 1 and 2. Mechanical thinning of woodland, forest, or world-land / urban interface is performed by means well known to practitioners of such operations. In this operation and by means of the system according to the present disclosure, it is not necessary to harvest or damage large trees not deemed to be part of the area fire fuel load. Material such as woody underbrush, manzanita, down, dead, and even rotting wood, is gathered in this step, leaving viable trees alone. Material infected with a fungal pathogen such as that causing Sudden Oak Death is equally desirable and suitable. The gathering of such “secondary forest products” is reflected by step 20 in FIG. 2.

[0024] The material as gathered is then processed by a suitably-sized wood reduction apparatus 22 such as a “hog grinder,” or “tub grinder,” which may be at a site immediately adjacent to a location at which the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| temperatures | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com